Sealed N2 cleaning device

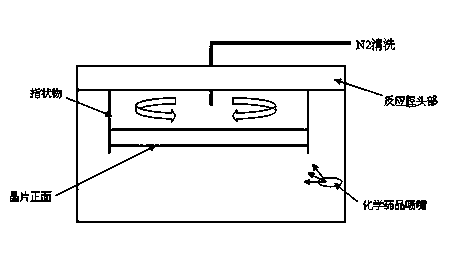

A cleaning device and sealing ring technology, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of N2 cleaning adapter 102 leakage, wafer backside contamination, etc., and achieve the effect of improving sealing conditions and avoiding chemical pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

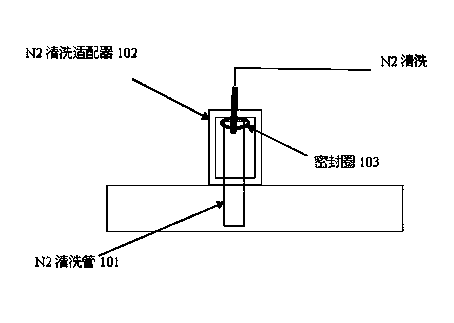

[0011] based on the following image 3 Preferred embodiments of the present invention will be described in detail.

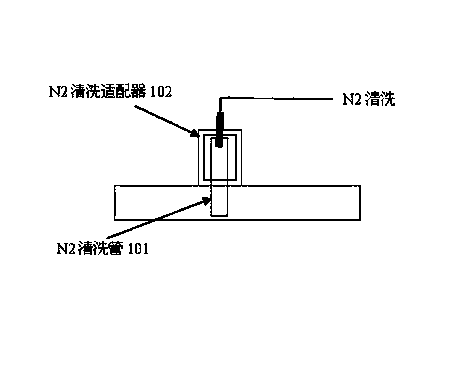

[0012] like image 3 As shown, the present invention provides a sealed N2 cleaning device, which includes an N2 cleaning tube 101 and an N2 cleaning adapter 102, and also includes a sealing ring 103 arranged on the contact surface of the N2 cleaning tube 101 and the N2 cleaning adapter 102;

[0013] The sealing ring 103 is an O-ring;

[0014] The O-shaped sealing ring is fluororubber or silicon fluororubber which can resist corrosion and provide airtight function.

[0015] Although the content of the present invention has been described in detail through the above preferred embodiments, it should be understood that the above description should not be considered as limiting the present invention. Various modifications and alterations to the present invention will become apparent to those skilled in the art upon reading the above disclosure. Therefore, the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com