High-temperature material vertical cooler and waste heat using system

A technology for high temperature materials and coolers, which is applied in the treatment of discharged materials, waste heat treatment, and energy efficiency improvement, etc., can solve the problems of high cost of grate coolers, difficult utilization of waste heat in low temperature sections, waste of sensible heat resources, etc. The effect of compactness, reduction of dust pollution, and reduction of electricity burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

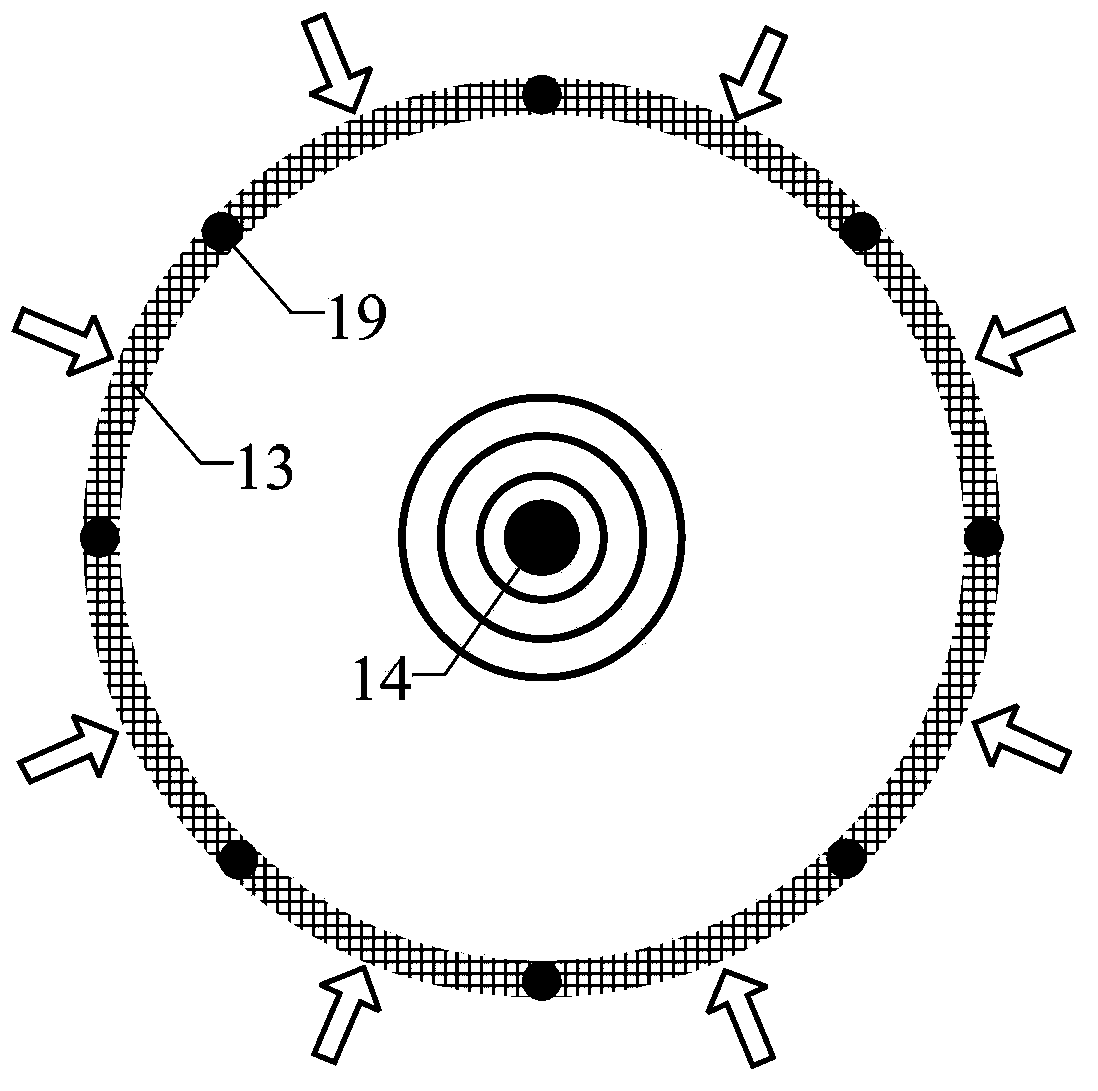

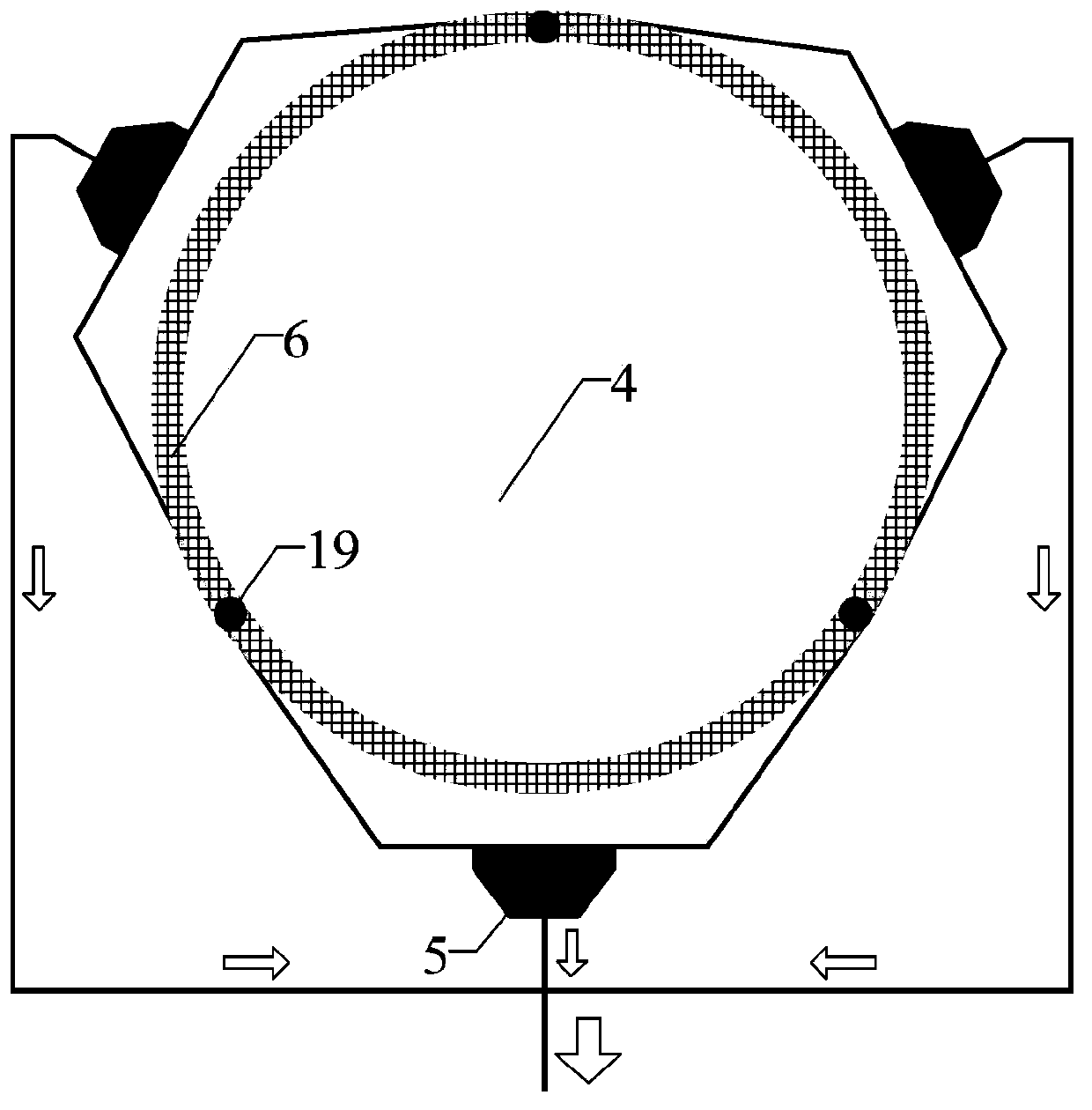

[0022] refer to figure 1 As shown, the present invention first proposes a vertical cooling machine for high-temperature materials, which includes a cylindrical body supported by a bracket 19. The lower part of the body is a cold air input section, the middle part is a cooling section 4, and the upper part is a material input section; The bottom of the cold air input section is provided with an upper cone bucket 15 for receiving materials, and a wind cap 14 is arranged in the center of the upper cone mouth of the upper cone bucket 15. The wind cap 14 is connected with an air duct extending out of the machine body. The cold wind input The lower end wall of the section is provided with a louver air inlet 13; the wall of the cooling section 4 is provided with a water-cooled wall 10, and the middle part of the cooling section 4 is provided with a cooling pipe 9, and the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com