Disc-shaped MgF2 crystal filming material and production method thereof

A technology for forming magnesium fluoride and a production method, which is applied in the field of disk-shaped magnesium fluoride MgF2 crystal coating material and its production field, can solve the problems of unbalanced heating of crucibles, limited quantity and length, and long time consumption, and achieve improved surface finish , no outgassing evaporation surface, excellent internal quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiment:

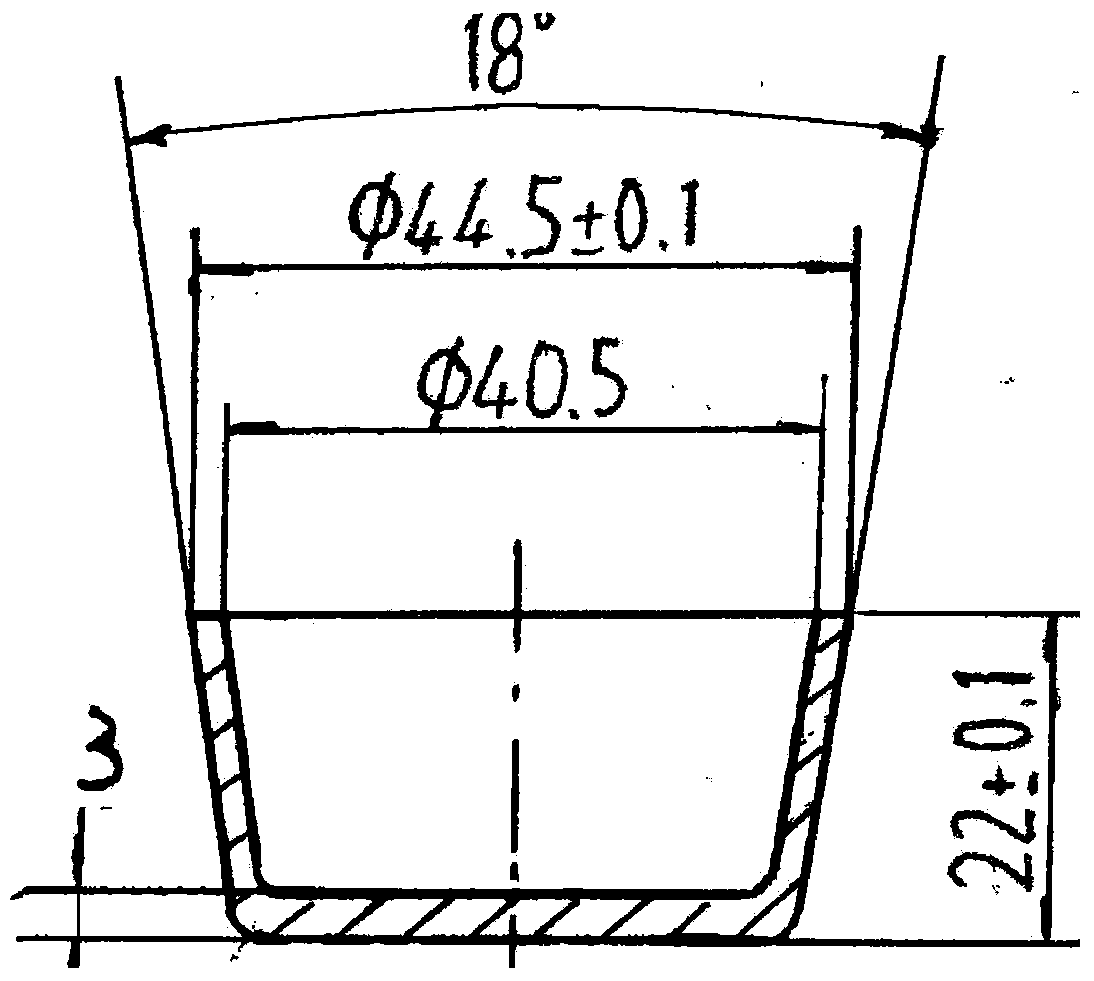

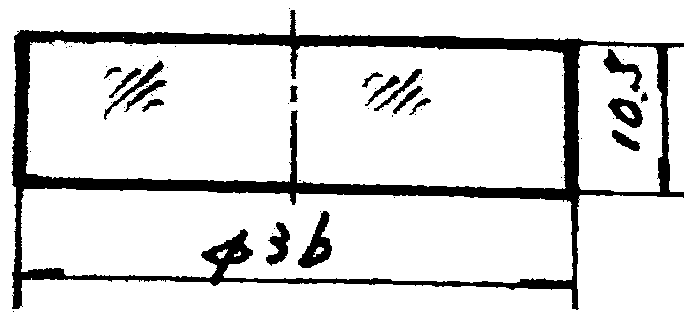

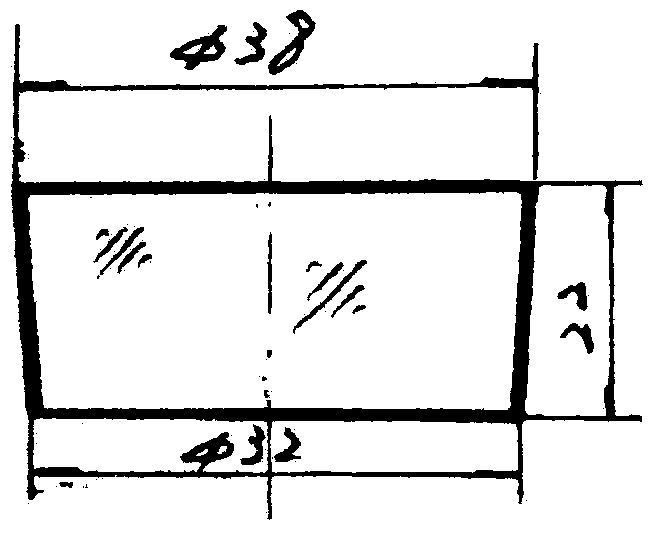

[0030] A disc-shaped magnesium fluoride crystal coating material of the present invention is a colorless and transparent polycrystalline optical crystal, at a wavelength of 500mm, its refractive index Ne=1.38, and the material density is about 3.17 grams / cm 3 ;The shape of the material is a disc shape or a conical column shape designed and processed to suit the diameter and depth of various specifications of electron gun crucibles or crucible linings. Its diameter ranges from 20mm to 56mm, and its thickness ranges from 5mm to 30mm;

[0031] The production method of the material includes two processes of vacuum sintering magnesium fluoride rod crystal and optical mechanical forming process, wherein: 1) the process steps of vacuum sintering magnesium fluoride rod crystal are:

[0032] ①Heating up: Put the magnesium fluoride powder into the vacuum sintering device to evacuate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com