Blast furnace soft water closed-recirculation cooling system

A circulating cooling system, soft water sealing technology, applied in the direction of cooling devices, etc., can solve the problems of the system not saving energy, the difficulty of commissioning and commissioning, and the small amount of cooling circulating water, so as to reduce the initial investment, reduce the total circulating water volume and lift of blast furnace cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

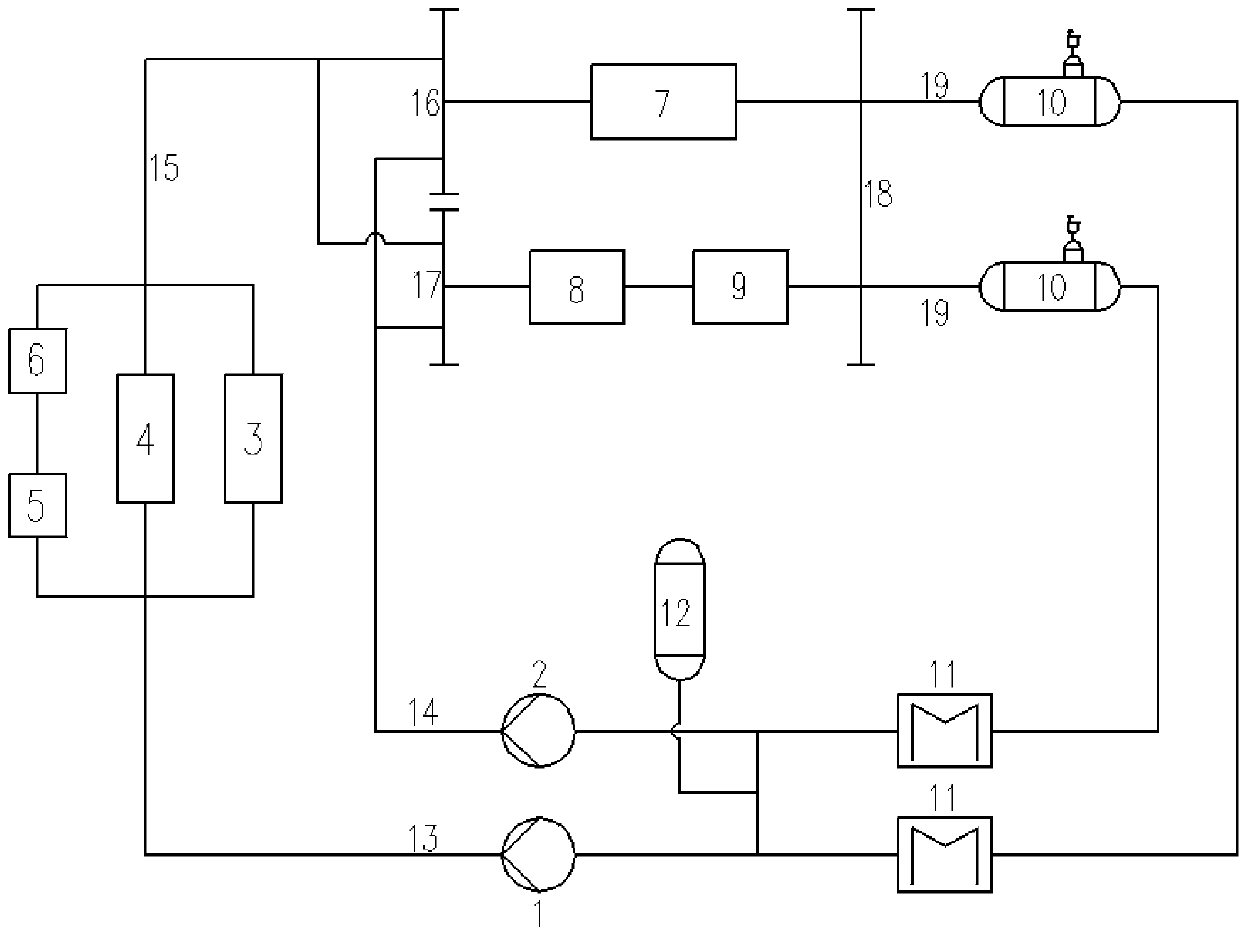

[0017] The present invention includes high-pressure cooling equipment, low-pressure cooling equipment, degassing tank 10, heat exchanger 11, pressure-stabilizing expansion tank group 12, water supply pump group, high-pressure water supply pipe 13, low-pressure water supply pipe 14, high-pressure return water pipe 15, cooling wall water supply Ring pipe 16, furnace bottom water supply ring pipe 17, return water ring pipe 18, return water main pipe 19; the water supply pump group is connected with high-pressure water supply pipe 13 and low-pressure water supply pipe 14 respectively, and high-pressure water supply pipe 13 is connected with series-parallel high-pressure cooling equipment The high-pressure cooling equipment is then connected to the high-pressure return pipe 15, the high-pressure return pipe 15 and the low-pressure water supply pipe 14 are connected in parallel and are connected to the stave water supply ring pipe 16 and the furnace bottom water supply ring pipe 17, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com