Hydrogenation coke method by adding coking distillate oil in residual oil

A technology of coking distillate oil and residual oil, which is applied in the field of adding coking distillate oil to residual oil for hydrogen coking, which can solve the problems of low quality petroleum coke, short furnace tube coking cycle, and low yield of liquid products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

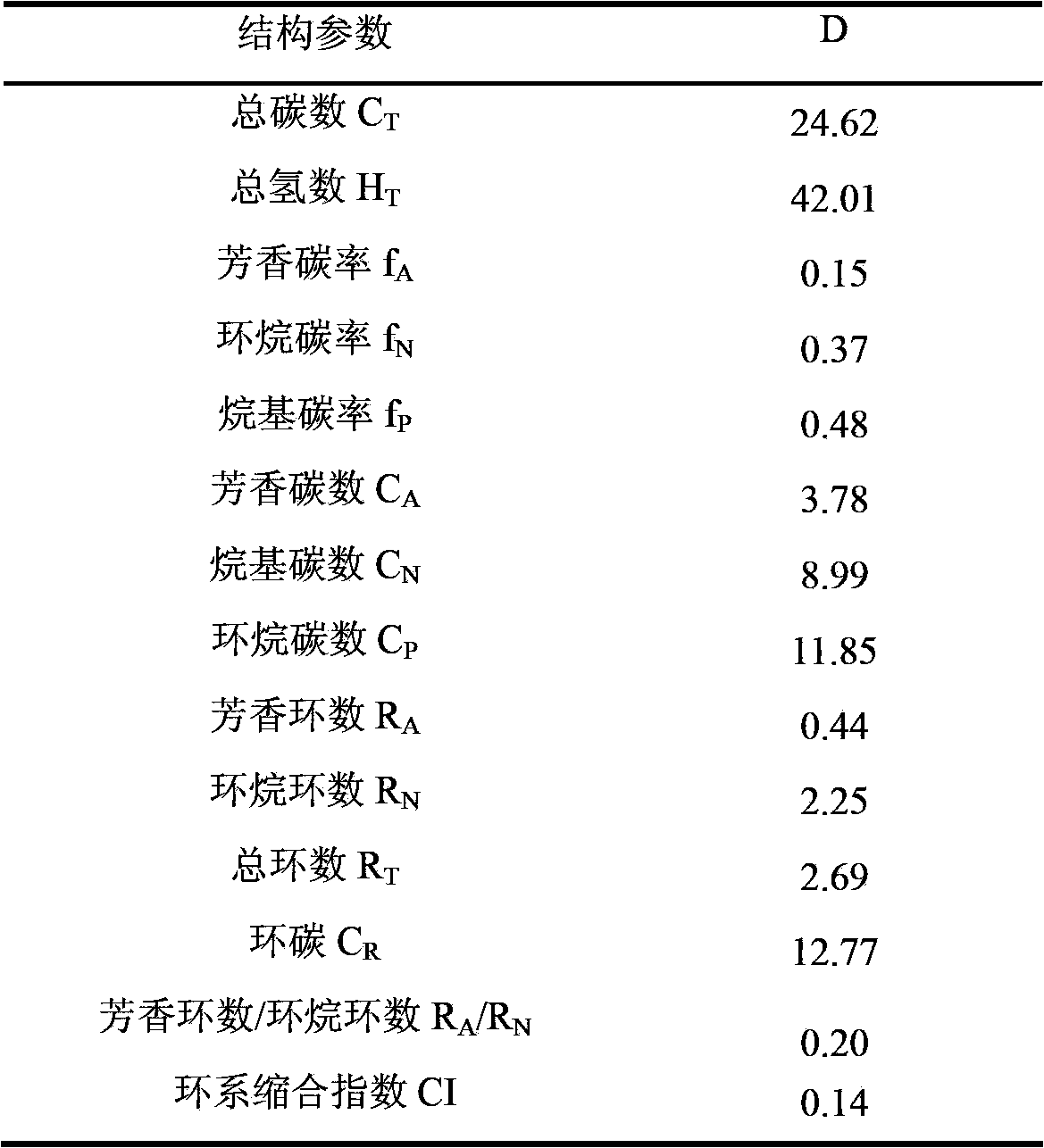

[0013] The properties of a typical hydrogen donor fraction are shown in Table 1.

[0014] Table 1 Structural parameters of hydrogen donor coking wax oil

[0015]

[0016] It can be seen that the naphthenic carbon content of this part of coking distillate oil is higher, so the concentration of active hydrogen atoms that can be transferred to other large aromatic free radicals that are easy to condense and generate coke is higher when heated, so in In the delayed coking process, using this part of the fraction to circulate will inevitably inhibit the coking of the furnace tube and the formation of shot coke, reduce the coke yield, and increase the yield of liquid distillate oil products. The alkyl carbon fraction of the hydrogen-donating wax oil component is low, indicating that the number of free radicals generated by this part of the alkyl carbon is the smallest when heated, so the probability of consuming its own potential hydrogen-donating capacity is the lowest. The rel...

Embodiment 2

[0020] The properties of a typical hydrogen donor fraction are shown in Table 1.

[0021] Table 3 Structural parameters of hydrogen donor coking wax oil

[0022]

[0023] Table 4 Changes in liquid recovery and coke production

[0024]

[0025] It can be seen that the naphthenic carbon content of this part of the coking distillate is low, and the alkyl carbon content of the hydrogen-donating wax oil component is relatively high, so the effect after its addition is not as good as that of the distillate D. The amount of coke produced and the effect of liquid collection are not good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com