Starch composition, starch-based film, and preparation method of starch-based film

A composition and starch-based technology, applied in the fields of fully biodegradable films, starch-based films and their preparation, can solve problems such as poor water resistance, low mechanical strength, and unsatisfactory degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

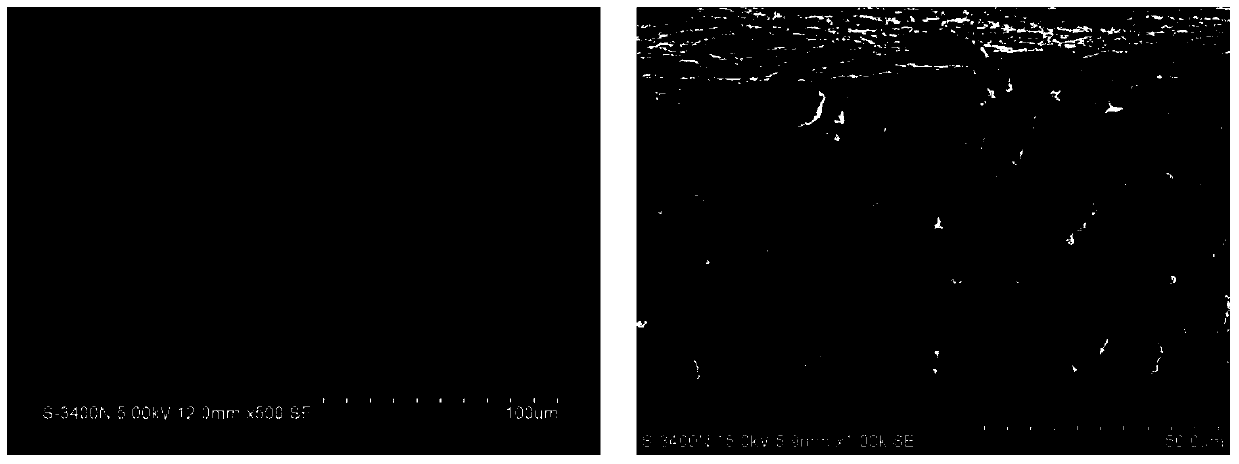

Image

Examples

preparation example Construction

[0058] The preparation method of the present invention comprises the following steps:

[0059](a) treating the gelatinized liquid of native starch with starch debranching enzyme, and performing a hydrolytic enzymatic cleavage reaction on the native starch to obtain an enzymatic starch paste;

[0060] (b) subjecting the enzymatic starch paste obtained in step a) to inactivation treatment, and then complexing and precipitating it with a polar complexing agent to obtain the starch composition.

[0061] In the present invention, the starch composition is prepared by an enzymatic digestion-compounding agent method, and the amylose content is greater than 90wt%, preferably more than 95wt%, more preferably more than 98wt%.

[0062] The starch debranching enzyme used in the present invention may be pullulanase, isoamylase or a combination thereof. The natural starch used is selected from the group consisting of potato starch, mung bean starch, tapioca starch, pea starch, corn starch,...

Embodiment 1

[0117] Take 600g of natural tapioca starch (amylose content 22wt%) and add it to the reaction kettle, add 0.7 liters of alcohol to disperse, then add 15 liters of 0.5mol / l NaOH solution, and heat at 80°C for gelatinization. Cool the gelatinized starch solution to 40°C, adjust the pH to about 6 with 2M hydrochloric acid solution, add 12g of starch pullulanase, and react for 15 minutes. Then gradually raise the temperature to 80°C, add 1.4 liters of n-butanol for complexation reaction for 2 hours, obtain a precipitate after cooling to room temperature, and centrifuge the precipitate, wash and filter the centrifuged product with alcohol, and dry it in vacuum at 60°C to obtain starch Composition, after testing, the amylose content in the final product is 96wt%.

[0118] Grind the starch composition into powder, weigh 100g of the starch composition powder, add alcohol to disperse, add water to make a starch composition aqueous suspension solution with a mass fraction of 5%, and hea...

Embodiment 2

[0121] Take 750g of potato starch (amylose content about 23wt%), add 0.8 liters of alcohol to disperse, pour the dispersion into the reaction kettle, and then add 16 liters of 0.5mol / l NaOH solution. Heat up to 85°C and maintain for 1.5 hours to fully gelatinize the starch. When cooling to 45°C, add hydrochloric acid to adjust the pH of the starch gelatinization solution to 6, then add 7g isoamylase and 5g pullulanase, and enzymatically hydrolyze for 20 minutes. Then the temperature was raised to 80° C., and 1.3 liters of isoamyl alcohol was added to carry out complexation reaction for 1.5 hours. Cool and stand overnight, and centrifuge to separate the crude starch composition. Wash the crude starch composition with ethanol to remove n-butanol, and then put it into a blast drying oven at 60°C to dry to obtain the final product of the starch composition. The amylose content is 95wt% after testing.

[0122] Grind the starch composition into powder, weigh 100g, add alcohol to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com