A kind of concave polyacrylonitrile nanoparticle and preparation method thereof

A polyacrylonitrile and nanoparticle technology, which is applied in the field of concave polyacrylonitrile nanoparticles and their preparation, can solve the problems of increasing the difficulty of large-scale production and production cost, complicated post-processing process, complicated preparation process, etc., and achieve excellent optical properties. and mechanical properties, simplify the post-processing process, and simplify the synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

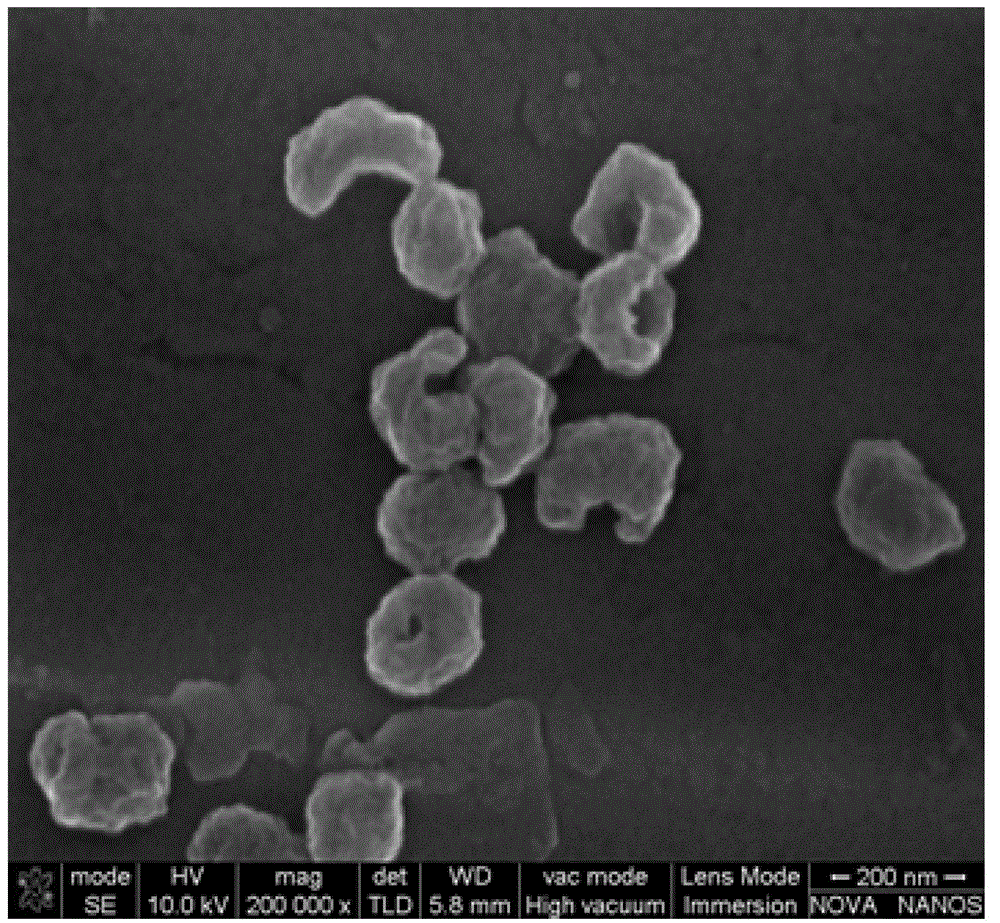

Embodiment 1

[0040] (1) Add 0.8g of hexadecane to 10g of acrylonitrile monomer and mix evenly to form an oil phase. Dissolve 0.1886g of sodium lauryl sulfate in 89.0014g of deionized water to form a water phase.

[0041] (2) Under magnetic stirring at a speed of 1200 rpm, add the oil phase to the water phase at a flow rate of 8 ml / min, and continue stirring for 20 min to form a coarse emulsion.

[0042] (3) Place the coarse emulsion obtained in step (2) in an ice-water bath, use an ultrasonic cell breaker (BRANSONModels450) at a duty cycle of 67% (work for 2 seconds in a duty cycle, stop for 1 second), and output frequency at 20KHz, Under the condition of an output power of 260W, ultrasonic crushing was performed for 6 minutes to obtain acrylonitrile monomer miniemulsion.

[0043] (4) Put the monomer fine emulsion obtained in step (3) into a 250mL four-neck flask, stir, blow nitrogen, add 0.15g of potassium persulfate after heating up to 75°C, and react at constant temperature for 4 hours,...

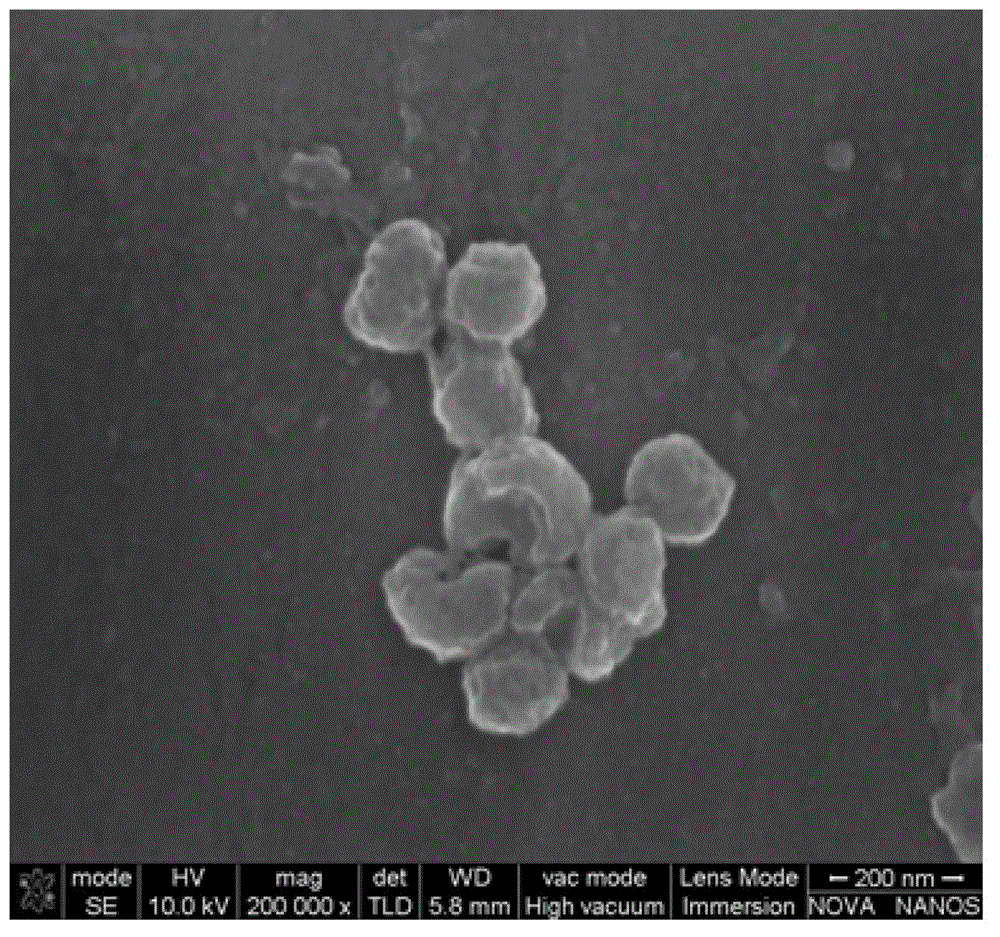

Embodiment 2

[0047] (1) Add 0.8g of hexadecane to 10g of acrylonitrile monomer and mix evenly to form an oil phase. Dissolve 0.1886g of sodium tetradecyl sulfate in 88.8614g of deionized water to form a water phase.

[0048] (2) Under magnetic stirring at a speed of 800 rpm, add the oil phase to the water phase at a flow rate of 2 ml / min, and continue stirring for 20 min to form a coarse emulsion.

[0049] (3) Place the coarse emulsion obtained in step (2) in an ice-water bath, use an ultrasonic cell breaker (BRANSONModels450) at a duty cycle of 67% (work for 2 seconds in a duty cycle, stop for 1 second), and output frequency at 10KHz, Under the condition of output power of 160W, ultrasonic crushing was carried out for 10 minutes to obtain acrylonitrile monomer miniemulsion.

[0050] (4) Put the monomer fine emulsion obtained in step (3) into a 250mL four-necked flask, stir, blow nitrogen, add 0.01g of potassium persulfate after heating up to 75°C, react at constant temperature for 4 hours...

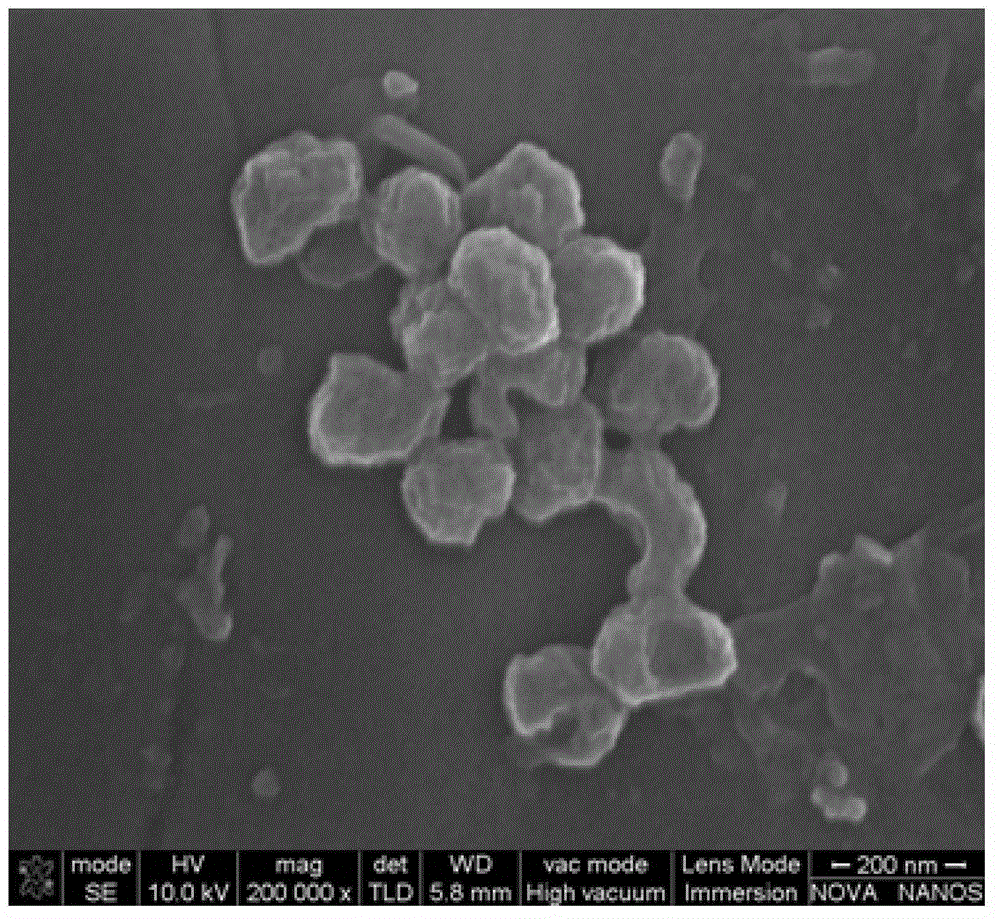

Embodiment 3

[0054] (1) Add 0.8g of hexadecane to 10g of acrylonitrile monomer and mix evenly to form an oil phase. Dissolve 0.1886g of sodium lauryl sulfate in 88.7114g of deionized water to form a water phase.

[0055] (2) Under magnetic stirring with a rotation speed of about 1500 rpm, add the oil phase to the water phase at a flow rate of 10 ml / min, and continue stirring for 20 min to form a coarse emulsion.

[0056] (3) Place the coarse emulsion obtained in step (2) in an ice-water bath, use an ultrasonic cell breaker (BRANSONModels450) with a working cycle of 67% (working for 2 seconds in a working cycle, stop for 1 second), and an output frequency of 30KHz, Under the condition of output power of 360W, it was ultrasonically crushed for 2 minutes to obtain acrylonitrile monomer miniemulsion.

[0057] (4) Put the monomer fine emulsion obtained in step (3) into a 250mL four-neck flask, stir, blow nitrogen, add 0.3g potassium persulfate after heating up to 75°C, react at constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com