Method for increasing butene-2 yield through C4 fraction containing small amount of butadiene

A carbon four fraction, butadiene technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., to achieve good resistance to impurities and poisons, high isomerization rate, and reduce olefin loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Hydrogenation and isomerization operations are carried out in fixed-bed adiabatic reactors. The nickel-based catalyst prepared according to the method described in claim 2 is filled in the reactor, and the catalyst is sulfurized and activated in situ. The selective hydrogenation and isomerization operations of the ether C4 fraction containing 1.56% butadiene were carried out in a continuous manner.

[0015] During the hydroisomerization process, the operating conditions are as follows: Reactor inlet temperature: 60 o C; Reactor pressure: 1.2MPa

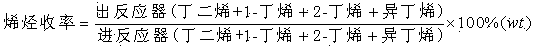

[0016] Liquid phase space velocity: 6h -1 , hydrogen / butadiene molar ratio: 2.15; see Table 1 for the composition of the material and the effluent of the hydroisomerization reactor operated under the above conditions.

[0017] Table 1

[0018]

Embodiment 2

[0020] Hydrogenation and isomerization operations are carried out in fixed-bed adiabatic reactors. The nickel-based catalyst prepared according to the method described in claim 2 is filled in the reactor, and the catalyst is sulfurized and activated in situ. The selective hydrogenation and isomerization operations of the raffinate C4 fraction containing 0.60% butadiene are carried out in a continuous manner.

[0021] During the hydroisomerization process, the operating conditions are as follows: Reactor inlet temperature: 60 o C; Reactor pressure: 1.4MPa; Liquid phase space velocity: 6h -1 Hydrogen / butadiene molar ratio: 2.67; See Table 2 for the composition of the hydroisomerization reactor effluent operated under the above-mentioned conditions.

[0022] Table 2

[0023]

Embodiment 3

[0025] Hydrogenation and isomerization operations are carried out in fixed-bed adiabatic reactors. The nickel-based catalyst prepared according to the method described in claim 2 is filled in the reactor, and the catalyst is sulfurized and activated in situ. The selective hydrogenation and isomerization operations of the ether C4 C4 fraction containing butadiene with a mass fraction of 0.21% were carried out in a continuous manner.

[0026] The operating conditions of hydroisomerization are as follows: Reactor inlet temperature: 70 o C; Reactor pressure: 1.6MPa; Liquid phase space velocity: 6h -1 , Hydrogen / butadiene molar ratio: 2.8; See Table 3 for the composition of the material and the effluent of the hydroisomerization reactor operated under the above conditions.

[0027] table 3

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com