Small grain SAPO-34 molecular sieve preparation method

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve characteristics such as silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, and can solve the problem of large grain size of SAPO-34 molecular sieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

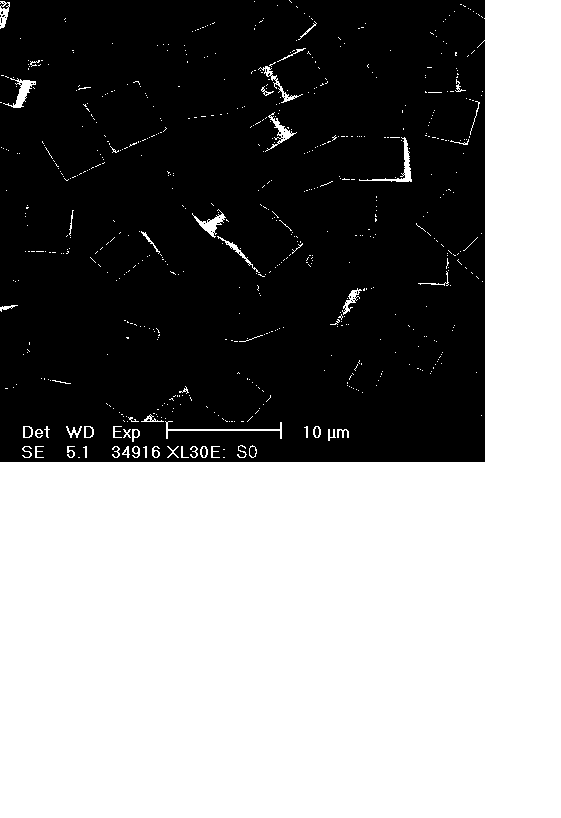

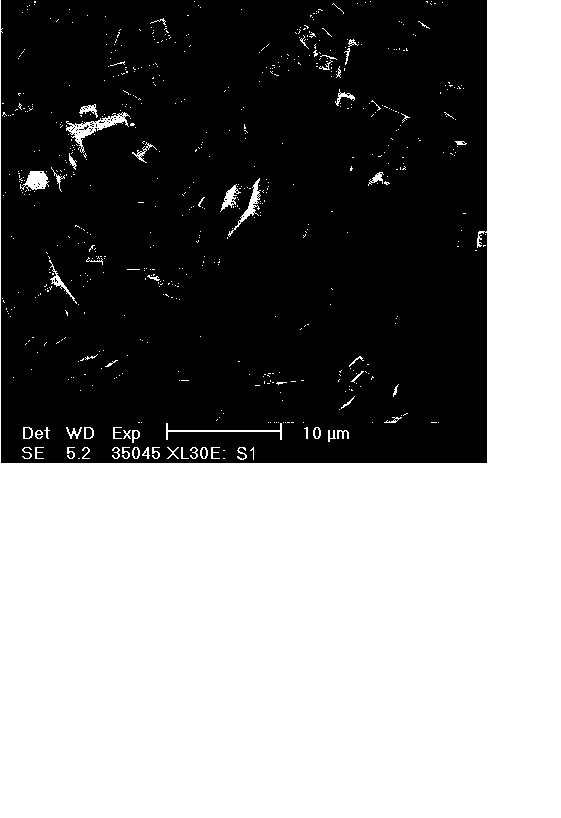

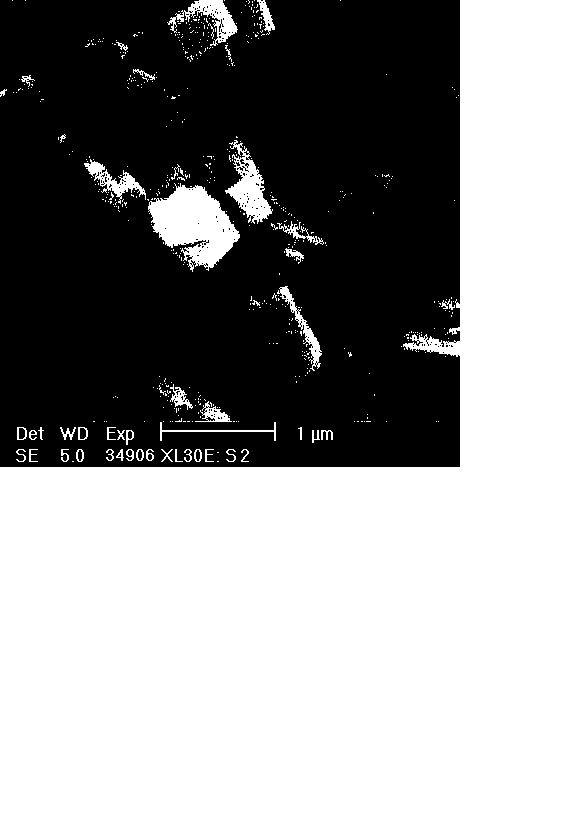

[0027] Prepare the initial crystallization solution in the same way as in Comparative Example 1. After the crystallization solution is crystallized at 200 °C for 4 hours in the crystallization tank, stop heating, cool to 120 °C, and keep it for 0.5 h. The temperature was raised to 200 °C again, and the crystallization was continued for 20 h; the obtained product was washed, centrifuged, and dried at 110 °C to obtain a solid sample. XRD results showed that the obtained product was SAPO-34 molecular sieve with an average grain size of 1.3 μm. figure 2 . The catalytic evaluation results of the MTO reaction showed that the selectivity of diene (ethylene + propylene) reached a high point of 81.9% when the reaction lasted for 45 minutes.

[0028]

Embodiment 2~5

[0030] The operation steps and experimental conditions are the same as in Example 1. In the first stage, crystallize at 200°C for 8 hours, cool to 120°C, keep for 0.5 h, then raise the temperature to 200°C at a rate of 2°C / min, and continue to crystallize for 20 h, the average particle size of the obtained samples and the MTO catalytic results are shown in Table 1.

[0031] Table 1

[0032]

Embodiment 6~8

[0034] The operation steps and experimental conditions are the same as in Example 1. In the first stage, the crystallization was performed at 200 °C for 4 hours, cooled to 150 °C, and kept for 0.5 h, then the temperature was raised to 200 °C at a rate of 2 °C / min to continue the crystallization n Hours, the average particle size of the obtained samples and the MTO catalytic results are shown in Table 2.

[0035]

[0036] Table 2

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com