Coupler knuckle push iron, railway vehicle coupler and railway vehicle

A technology of knuckle tongue and hook body, which is applied to railway car body parts, railway couplings, transportation and packaging, etc., to achieve the effects of improving strength, optimizing layout and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

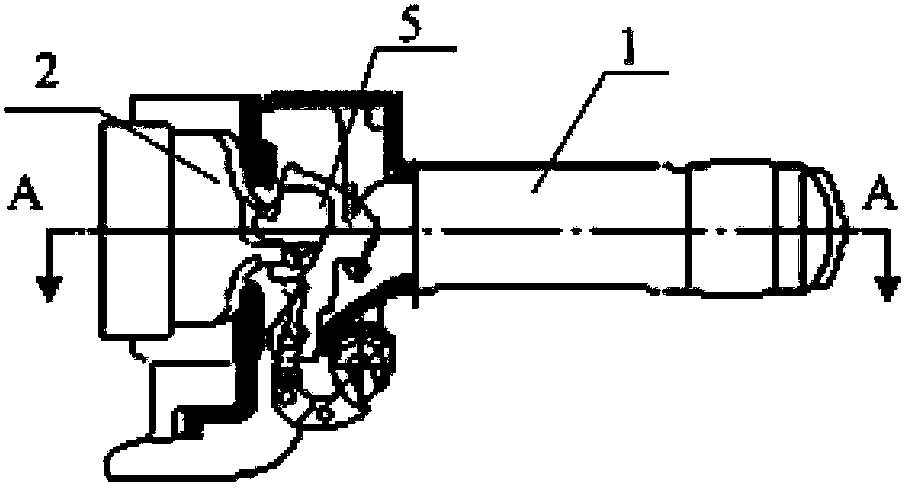

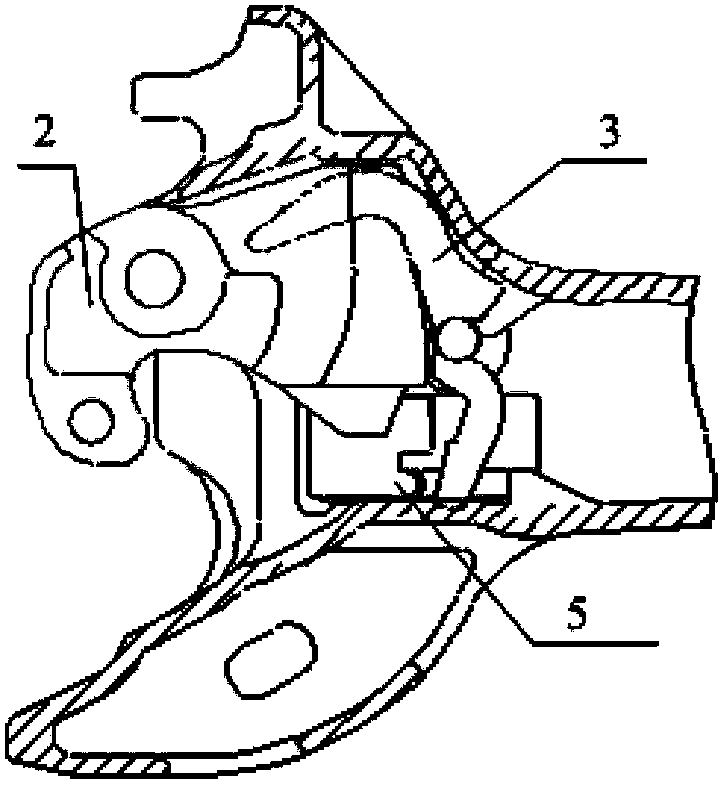

Image

Examples

Embodiment Construction

[0022] "Longitudinal" described in the present invention refers to the direction in which the rail extends; "front" refers to the running direction of the train; When the leg rotates around the push iron pin in the horizontal plane, the vertical projection of the kick leg when it is rotated to the maximum angle position relative to the longitudinal direction, and the vertical projection of the kick leg when it is rotated to the minimum angle position relative to the longitudinal direction, is when The longitudinal projection of the position of the kick leg when the coupler is in the locked and fully open states respectively.

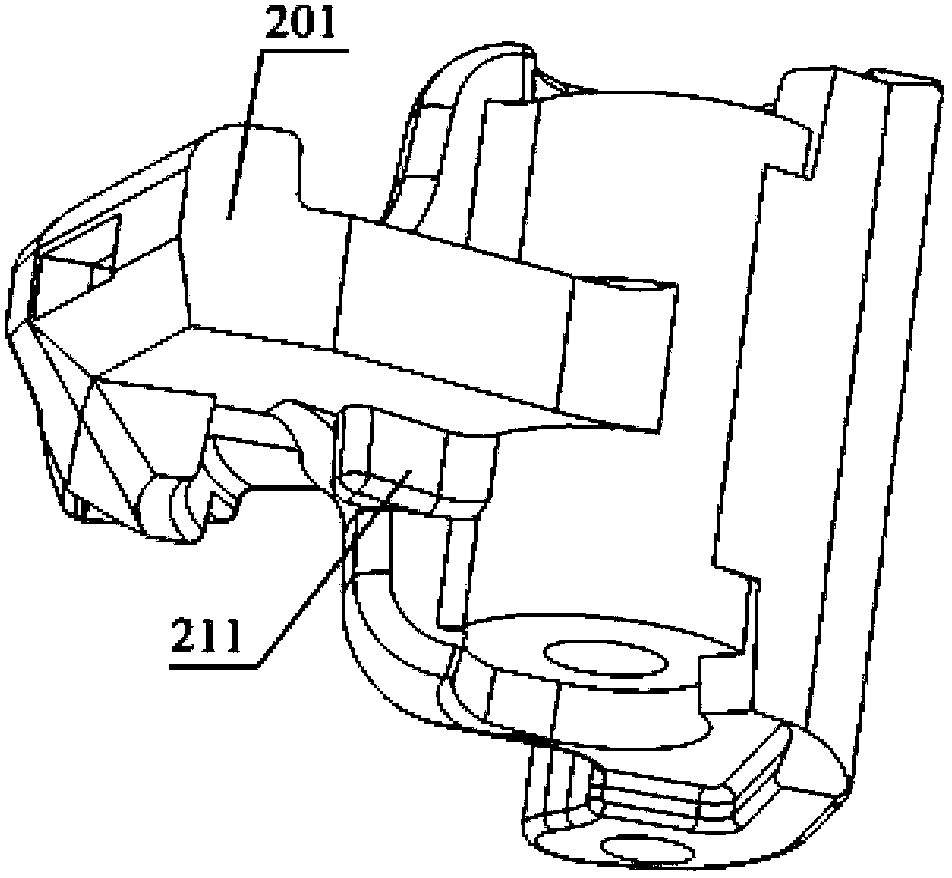

[0023] Figure 8 It is a perspective view of the tongue pushing iron in the railway vehicle coupler embodiment of the present invention; please refer to Figure 8 , the present embodiment provides a knuckle pusher, including: a pusher pin 73 vertically arranged for hinged connection with the hook body, and the pusher pin 73 is respectively fixedly provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com