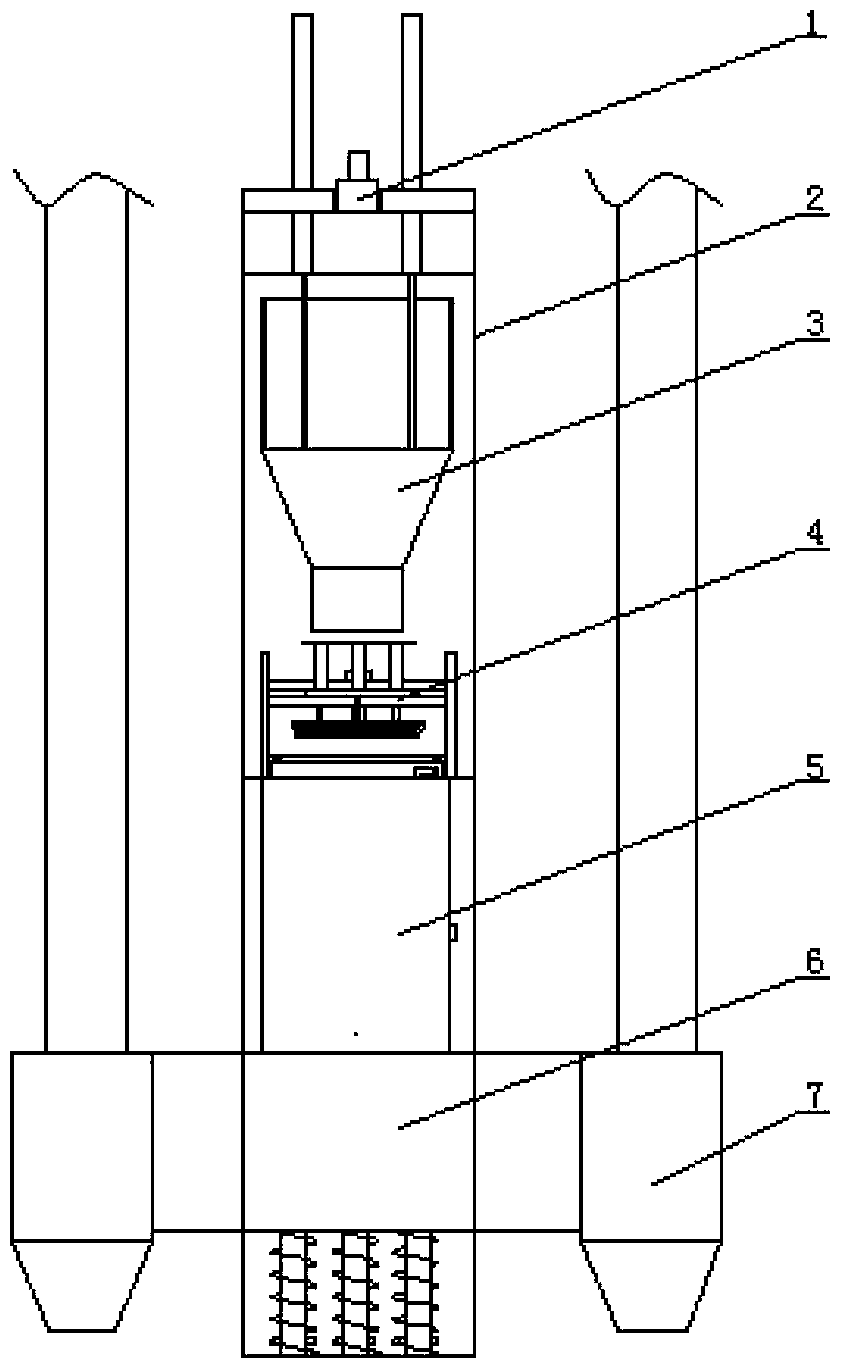

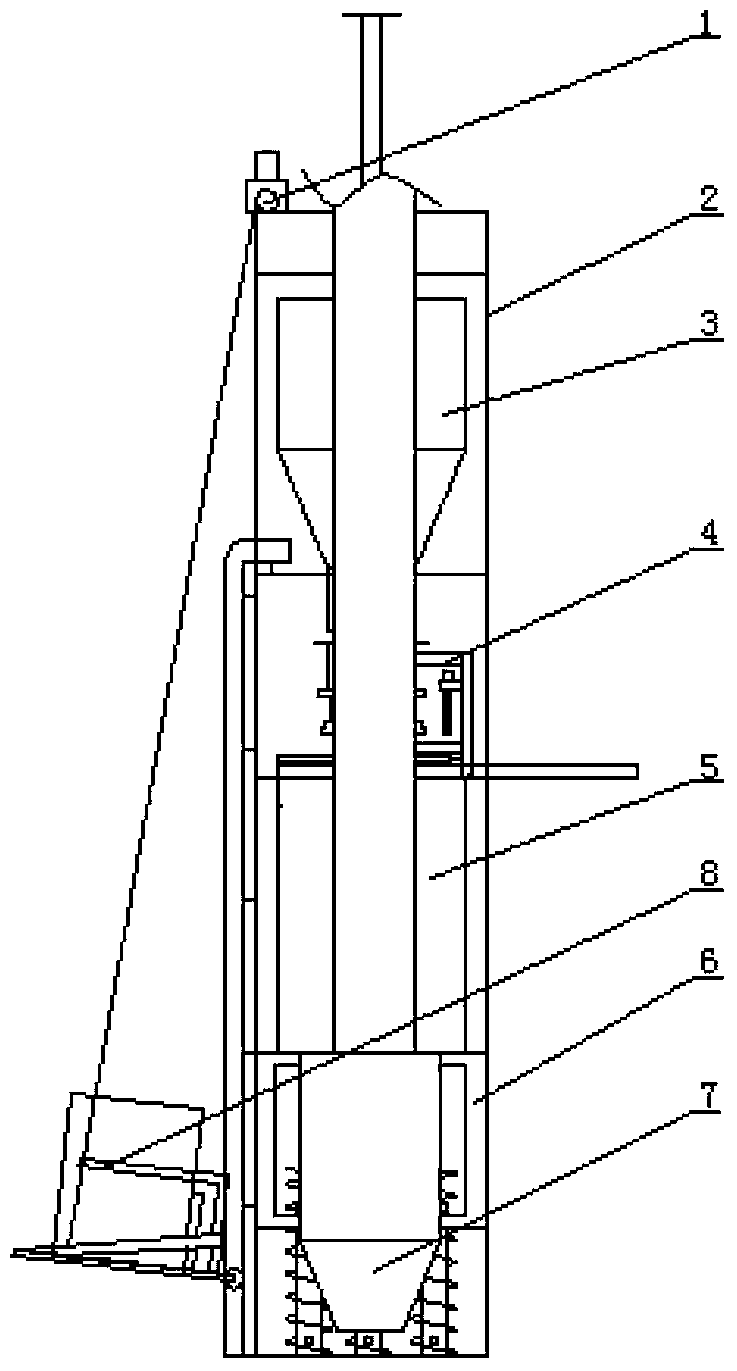

Steam-catapulting-type organic matter garbage disposal system

A waste treatment system and organic matter technology, applied in grain treatment, chemical instruments and methods, and solid waste removal, etc., can solve problems such as the inability of equipment to meet, and achieve the effect of stable support, convenient feeding, and fast feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0043] A steam ejection type organic waste treatment system, the system includes a system frame 2, a pressure maintaining ejection device 5, a pressure maintaining ejection device screw cap controller 4, a liftable feeding funnel 3, a feeding lifting device 8, and a discharge guide cylinder 6 , Vapor-solid separator 7, in the system frame from bottom to top install the pressure-holding ejection device, the pressure-holding ejection device screw cap controller, the liftable feeding funnel, install the feeding lifting device on one side of the system frame, and install the pressure-holding ejection device on the side of the system frame The lower part is equipped with a discharge guide cylinder, which is connected to a vapor-solid separator. Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com