High-performance Ag2O/Bi2WO6 compound light catalyst and preparing method thereof

A technology of composite light and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve unfavorable economical production, photogenerated electron-hole recombination rate Fast, complicated preparation steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

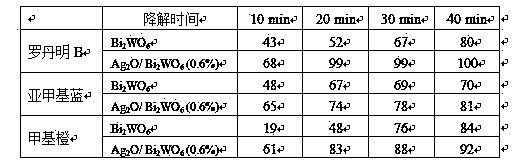

[0038] Bi 2 WO 6 Powder preparation method:

[0039] Weigh 0.3881 g (0.8 mmol) Bi(NO 3 ) 3 ·5H 2 O was dissolved in 17 mL of distilled water, and under vigorous magnetic stirring, 0.1319 g (0.4 mmol) of Na 2 WO 4 2H 2 O. After continuing to stir for 30 min, the white suspension was transferred to a 25 mL hydrothermal reactor, and reacted at a constant temperature of 160 °C for 12 h. After natural cooling to room temperature, the product was centrifuged, washed and dried to obtain pale yellow Bi 2 WO 6 Ultrastructure powder. The 5mg photocatalyst was illuminated by a 500W xenon lamp for 20min to 10mL 10 -5 The degradation rate of the M RhB test solution was 60%.

[0040] Ag 2 O / Bi 2 WO 6 The preparation example of the composite photocatalyst is as follows.

Embodiment 1

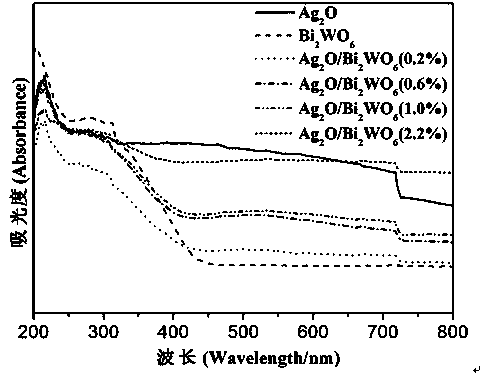

[0042] Weigh 0.1g Bi 2 WO 6 powder in a 50 mL beaker, add 2.0 mL (0.59×10 -3 mol / L) AgNO 3 Stock solution, stirred at room temperature for 20min, then added with AgNO 3 Equal metering ratio (0.25×10 -3 mol / L) NaOH stock solution 2.0 mL, continue to stir for 20 min, then centrifuge the precipitate, wash, and dry at 60°C, collect the brown-black powder to obtain Ag with a wt.% of 0.2% 2 O / Bi 2 WO 6 catalyst of light. The 5mg photocatalyst was illuminated by a 500W xenon lamp for 20min to 10mL 10 -5 The degradation rate of M RhB test solution was 72.6%.

Embodiment 2

[0044] Weigh 0.1g Bi 2 WO 6 powder in a 50 mL beaker, add 6.0 mL (0.59×10 -3 mol / L) AgNO 3 Stock solution, stirred at room temperature for 20min, then added with AgNO 3 Equal metering ratio (0.25×10 -3 mol / L) NaOH stock solution 6.0ml, continue to stir for 30min, then centrifuge the precipitate, wash, and dry at 60°C, collect brown-black powder to obtain Ag with 0.6% Ag wt.% 2 O / Bi 2 WO 6 catalyst of light. The 5mg photocatalyst was illuminated by a 500W xenon lamp for 20min to 10mL 10 -5 The degradation rate of the M RhB test solution was 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com