automatic bread maker

A technology for automatic bread making, applied in toasting devices, household appliances, applications, etc. It can solve problems such as adverse effects, starch damage ratio, difficulty in taking out bread, etc., and achieve excellent kneading performance and prevent splashing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

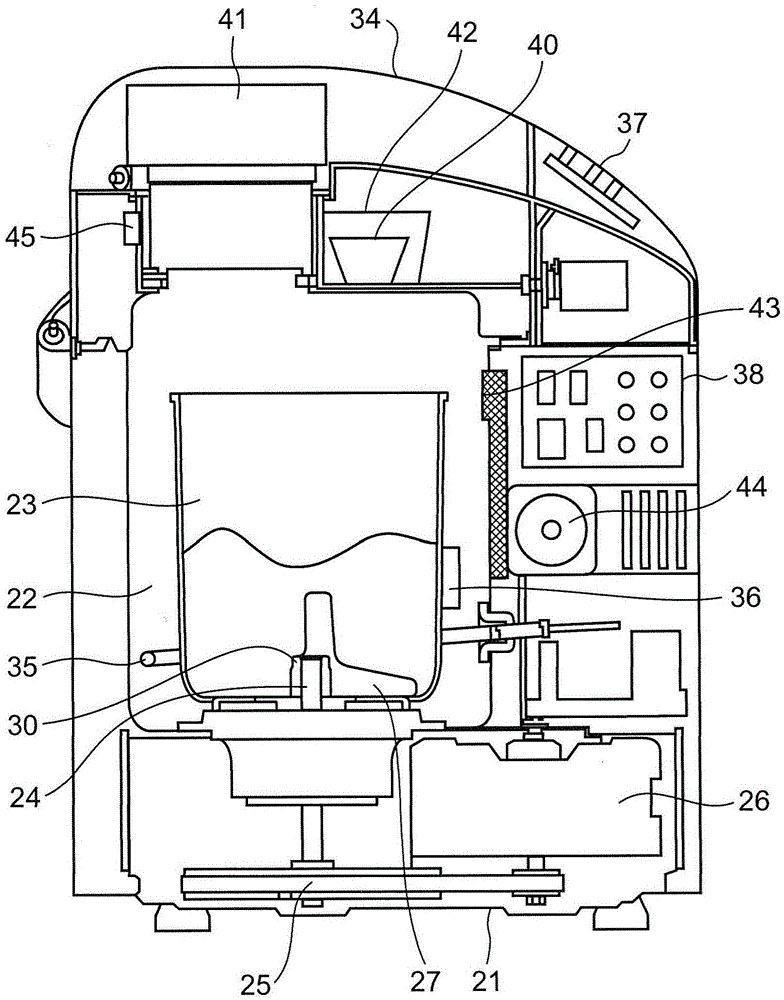

[0109] figure 1 It is a cross-sectional view showing the structure of the automatic bread maker according to Embodiment 1 of the present invention. figure 2 It is a control block diagram of the automatic breadmaker in Embodiment 1 of this invention.

[0110] Such as figure 1 As shown, the automatic bread making machine of Embodiment 1 is equipped with: a baking chamber 22 provided inside the equipment main body 21; a bottomed container (baking box) 23, which is detachably stored in the baking chamber cooking ingredients. In this container 23 , a rotating shaft 24 is drawn out through the bottom surface of the container 23 , and a D-cut portion having a D-shaped cross section perpendicular to the axial direction is formed on the rotating shaft 24 . That is, the lead-out end of the rotating shaft 24 is arranged at the center of the bottom surface of the container 23 . The rotary shaft 24 is connected to a motor 26 via a power transmission unit 25, for example, a V-belt. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com