Machine vision-based safety fuse gunpowder density nondestructive testing method and machine vision-based safety fuse gunpowder density nondestructive testing system

A non-destructive testing and machine vision technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as hidden safety hazards, high missed detection rate, high price, etc., and achieve the effect of strong practicability, good stability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

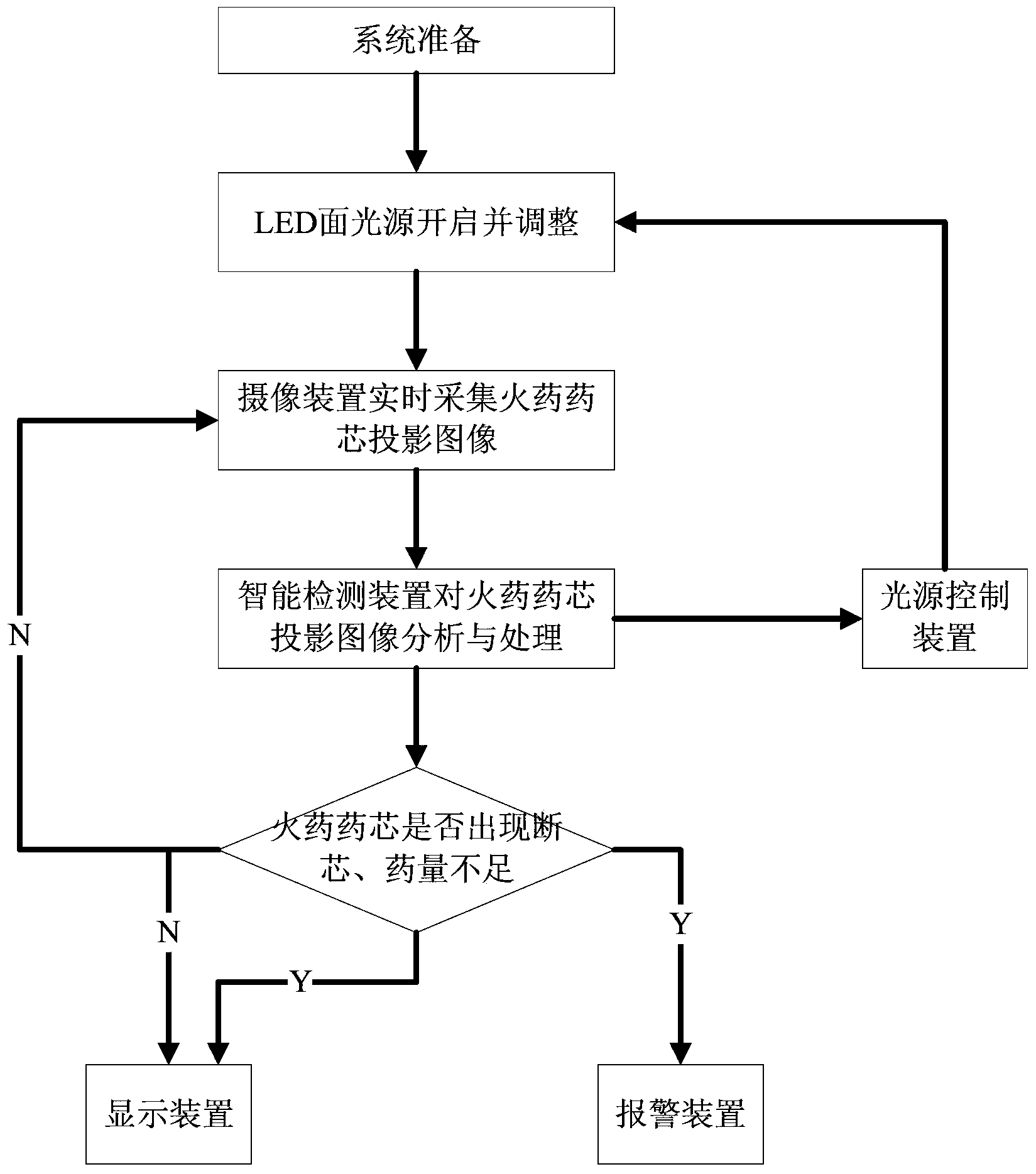

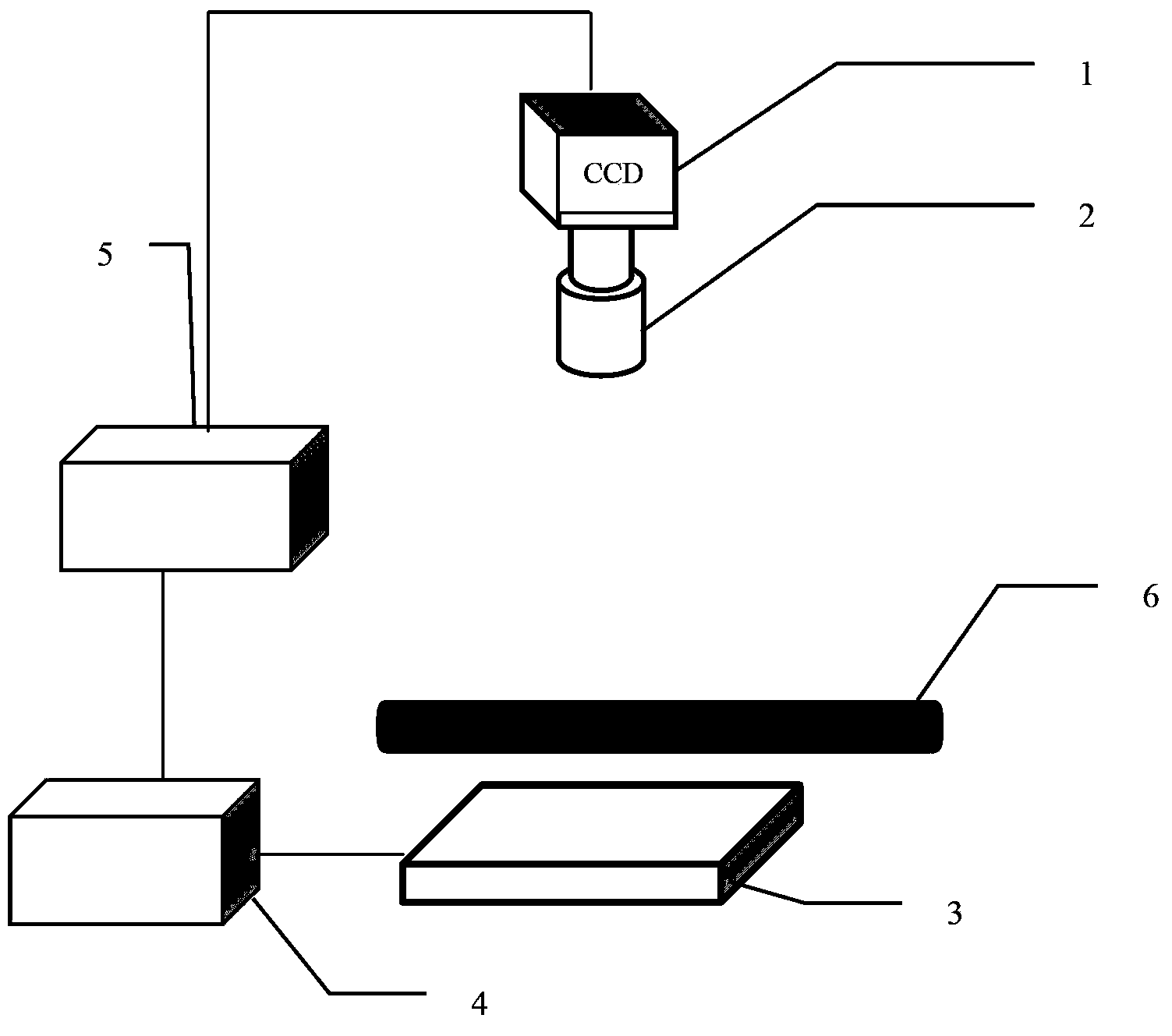

[0037] see Figure 1 to Figure 7 , the non-destructive detection method of fuse gunpowder density based on machine vision provided by the invention, it comprises the steps:

[0038] (1), a camera device 1 is set, which is used to collect fuse and gunpowder core perspective images;

[0039] (2), a light source control device 4 is set, which is used to adjust the illumination brightness of the light source, and make the light source produce a uniform light-emitting surface;

[0040] (3), a display device is provided for displaying the current processing result;

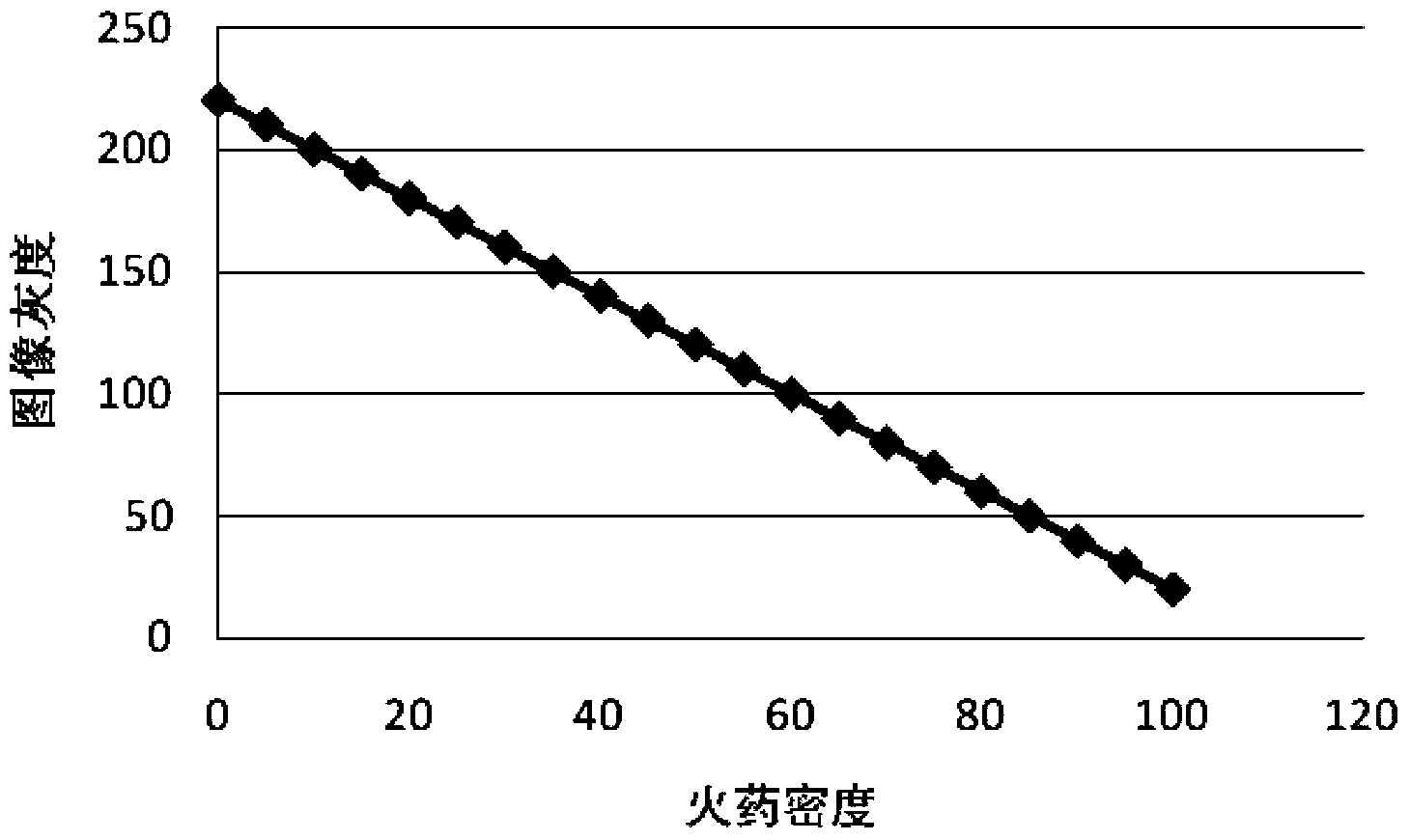

[0041] (4), an intelligent detection device 5 is set, and described intelligent detection device 5 is provided with a digital image processing chip, is integrated with the analysis software based on the grayscale analysis method in the image processing and the black and white center of gravity method in the described digital image processing chip, Based on the processing software of the mathematical model of the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com