A gas-hydraulic damping cylinder for vertical jacking

A gas-liquid damping cylinder and jacking technology, which is applied to fluid pressure actuating devices, servo motors, mechanical equipment, etc., can solve the problems of many potential leakage points, difficult assembly and maintenance, complicated pipelines, etc. Simplified structure and pipeline integration The effect of pipeline integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

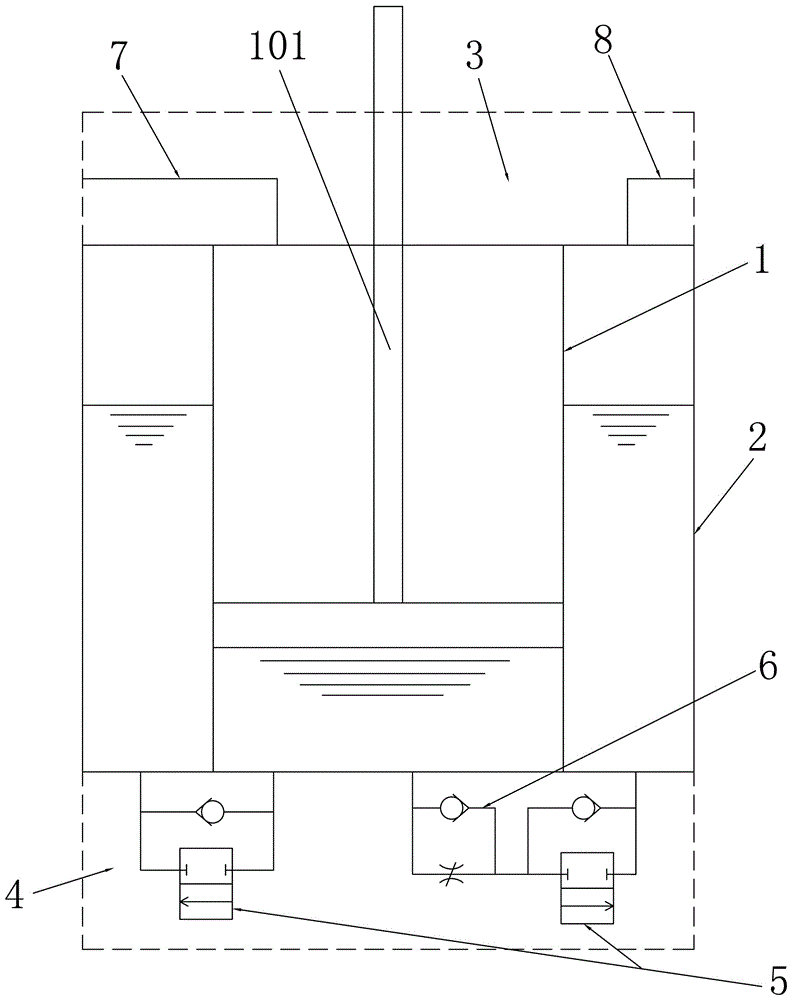

[0011] See attached figure 1 As shown, the gas-hydraulic damping cylinder described in this embodiment is mainly used for the vertical lifting of the descending brick stacker, and it includes a central hydraulic cylinder 1, an outer oil storage sleeve 2, a pneumatic cylinder head 3 and a hydraulic control Integrated cylinder base 4; among them, the hydraulic control integrated cylinder base 4 is provided with two independent hydraulic passages connecting the lower chamber of the central hydraulic cylinder 1 and the outer oil storage sleeve 2, and the two hydraulic passages are provided with one-way cut-off The valve 5 controls the flow of the liquid working medium from the lower chamber of the central hydraulic cylinder 1 to the outer oil storage sleeve 2; one of the two hydraulic passages is also provided with a one-way throttle valve 6 for opening the one-way stop valve 5 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com