System and method by means of power plant waste heat for conducting aeration cooling on mine

A technology for mine ventilation and waste heat from power plants, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. It can solve the problems of insufficient effective cooling capacity, large temperature rise, and high operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

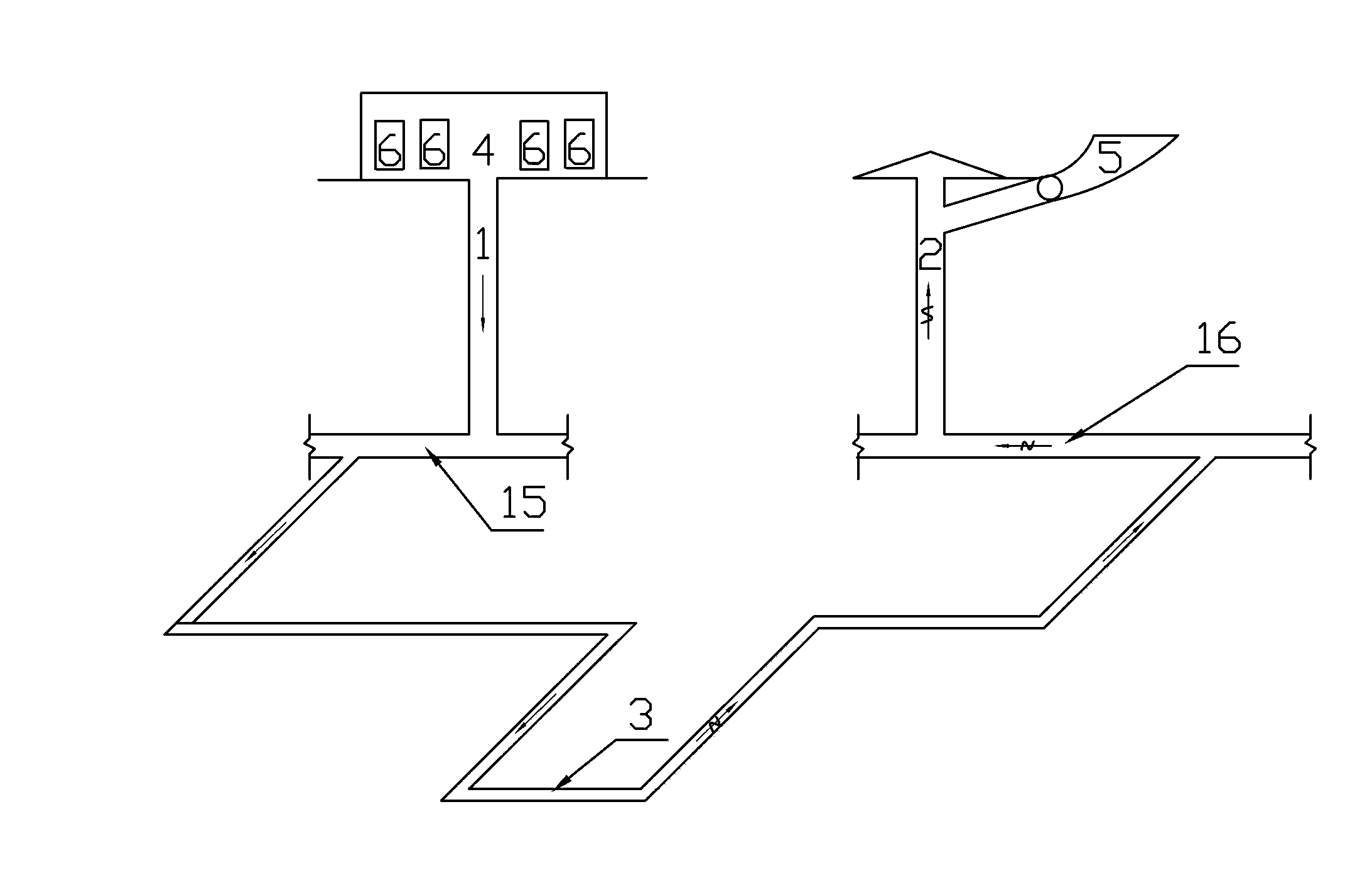

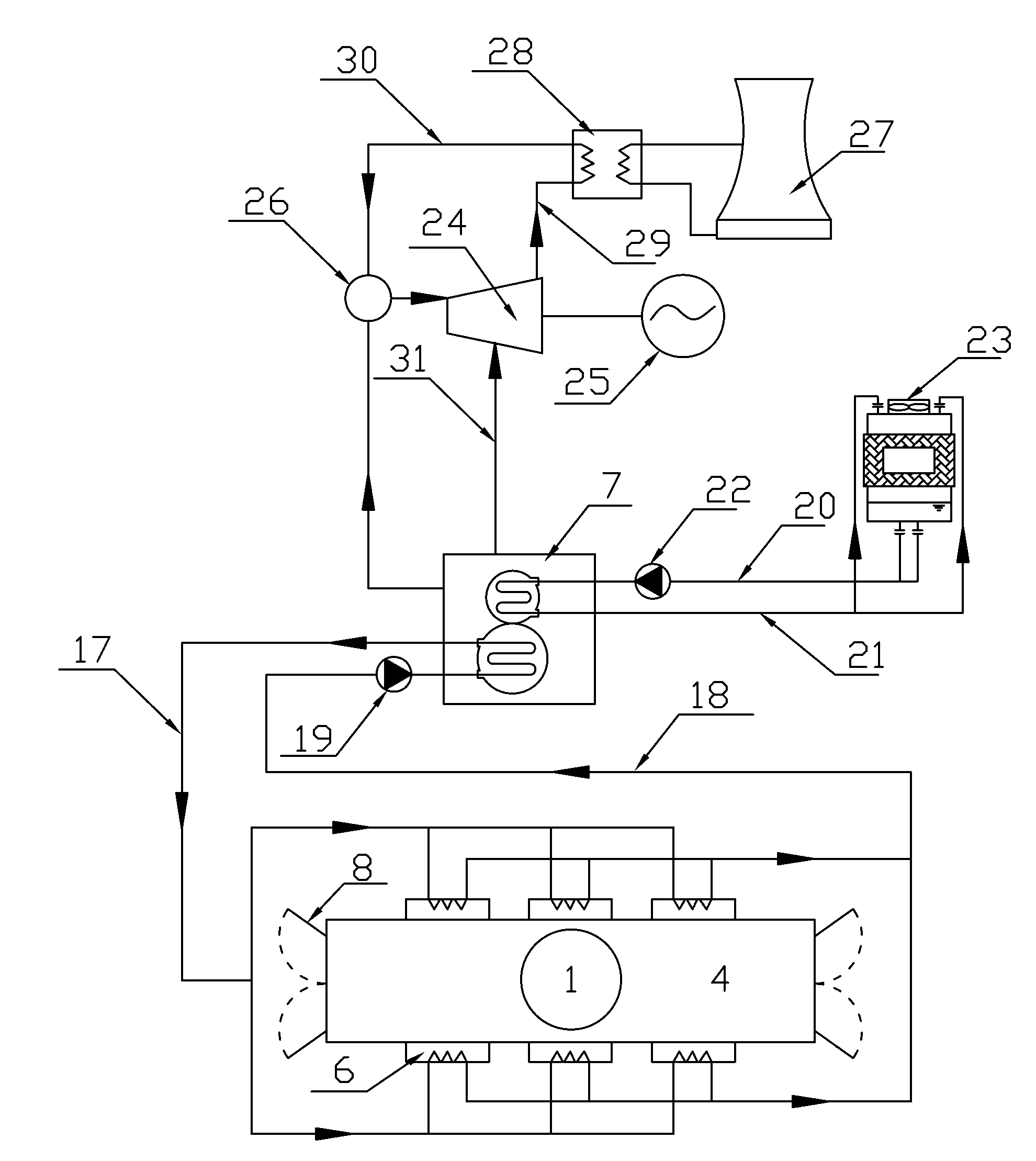

[0021] Implementation mode one: if figure 1 , 2 As shown, the present invention utilizes waste heat from a power plant to ventilate and cool a mine. The system includes an air intake shaft 1 and an exhaust shaft 2, which are communicated through a mine ventilation system roadway. A mine ventilator 5 is provided, and a personnel / material inlet and an air inlet are provided on the wellhead structure, and it is characterized in that: it also includes an air cooler 6 and a lithium bromide absorption refrigerator 7, and the air cooler 6 is arranged on the wellhead structure 4, The personnel / material inlet is provided with a damper 8; when the damper 8 is closed, the negative pressure generated by the mine ventilator 5 at the inlet wellhead will draw the ground air into the underground after being cooled and dehumidified by the air cooler; the lithium bromide absorption type The refrigerating machine 7 is arranged on the ground, and the lithium bromide absorption refrigerating mach...

Embodiment approach 2

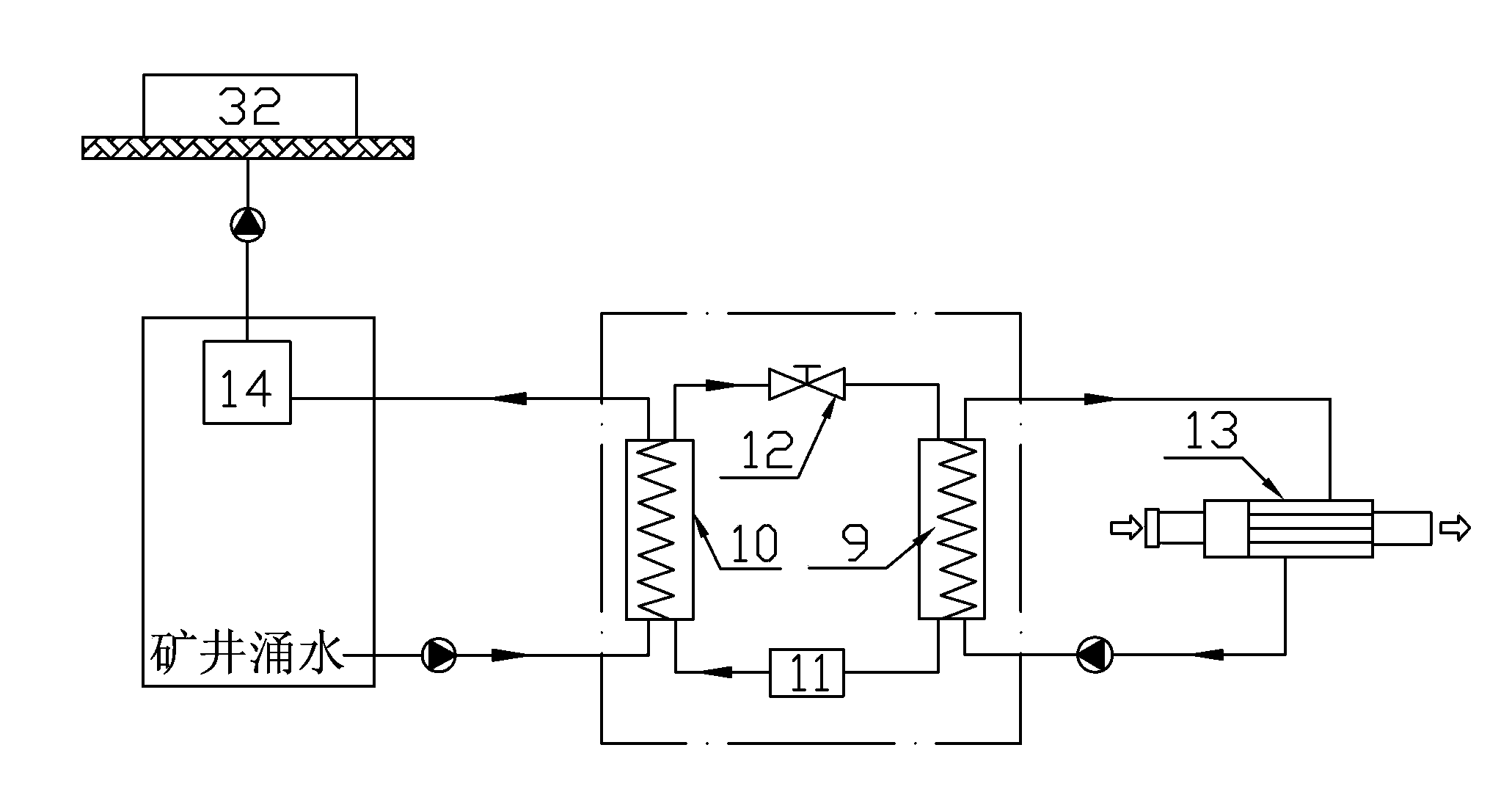

[0028] Implementation mode two: if image 3 Shown: the system of the present invention utilizes waste heat from power plants to ventilate and cool mines also includes local refrigeration equipment—underground mobile air-conditioning units. The downhole mobile air conditioner unit includes an evaporator 9, a condenser 10, a compressor 11, an expansion valve 12, an air cooler 13 and a condensing heat discharge system. The compressor 11 in the main engine sucks and compresses the low-pressure gaseous refrigerant that absorbs the superheat load It is high-pressure and high-temperature steam, and the heat is transferred to the cooling water through the condenser 10 in the main engine, and the refrigerant becomes a low-temperature and high-pressure liquid at the same time. Then the refrigerant in the low-temperature and high-pressure state passes through the expansion valve 12 to become a low-temperature and low-pressure gas-liquid two-phase mixture and enters the evaporator 9 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com