Spinning process of three-spinning-roller semicontinuous high-speed spinning machine

A technology of high-speed spinning and spinning process, applied in the field of spinning process, can solve the problems of short travel distance of the thread, unable to increase the spinning speed, insufficient reaction, etc., to achieve improved production efficiency, clear division of coagulation and acid removal, Conducive to the effect of upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

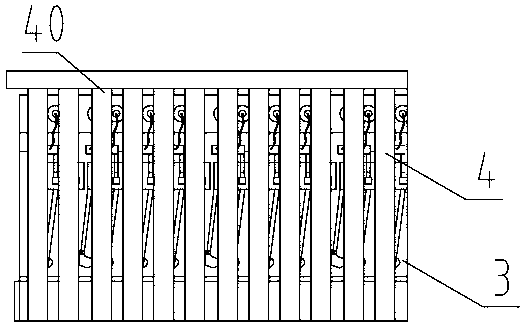

[0131] A spinning process of a semi-continuous high-speed spinning machine with three spinning rollers, including glue supply, filament molding, spinning and winding, and the spinning is completed by a spinning device 4, which includes three relative Spinning rollers 40 arranged laterally on the operating surface 102 of the spinning surface 101, the three spinning rollers 40 are respectively drafting rollers 404, coagulation rollers 405 and acid removal rollers 406, and the filaments 8 surround the drafting rollers 404, The coagulation roll 405 and the acid removal roll 406 complete the drafting, coagulation and acid removal in the spinning step under the rotation of the spinning roll 40; the speed control of the drafting roll 404, the coagulation roll 405 and the acid removal roll 406 is The following combinations:

[0132] The speed of the drafting roller 404 is controlled to be 30r / min; the speed of the coagulation roller 405 is controlled to be 900r / min; the speed of the a...

Embodiment 2

[0149] On the basis of embodiment 1, concrete process route is:

[0150] The viscose spinning stock solution is supplied with glue through the rubber supply pipe 202, the flow rate is controlled by the metering pump 201, and then enters the spinneret 301 through the filter 203, and the spinneret on the spinneret 301 sprays out filaments, and the filaments enter the tube to form After the device 303 or the bath molding device 302 is solidified and formed, the formed filaments travel to the spinning roll 40 arranged transversely relative to the operating surface 102 of the spinning surface 101, and the filaments surround the spinning roll 40 and are completed under the rotation of the spinning roll 40. Drafting, coagulation and deacidification in the spinning step, in the process of said drafting, coagulation and deacidification, the filaments are also washed with water by the washing device 42, and the filaments are exported from the spinning roll 40 and passed through the funne...

Embodiment 3

[0152] On the basis of embodiment 1, preferred:

[0153] The semi-continuous high-speed spinning machine includes a frame 1, and the two ends of the three spinning rollers 40 are respectively fixed above the two sides of the frame 1 and connected to the driving device for rotation.

[0154] Further, the three spinning rollers 40 are respectively connected with the driving device, which can realize independent and real-time speed-adjusted rotation.

[0155] The above solution can more easily control the speed coordination of each spinning roller 40, realize real-time online speed regulation, and also can change the specifications and types of filaments online without replacing gears and other transmission components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com