Perchlorate electrolyzer and electrolytic process

A perchlorate and electrolysis device technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of increased difficulty in process control, low chlorate conversion rate, low chlorate concentration, etc., to improve the reaction Speed, reduce the concentration of air bubbles, strengthen the effect of circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

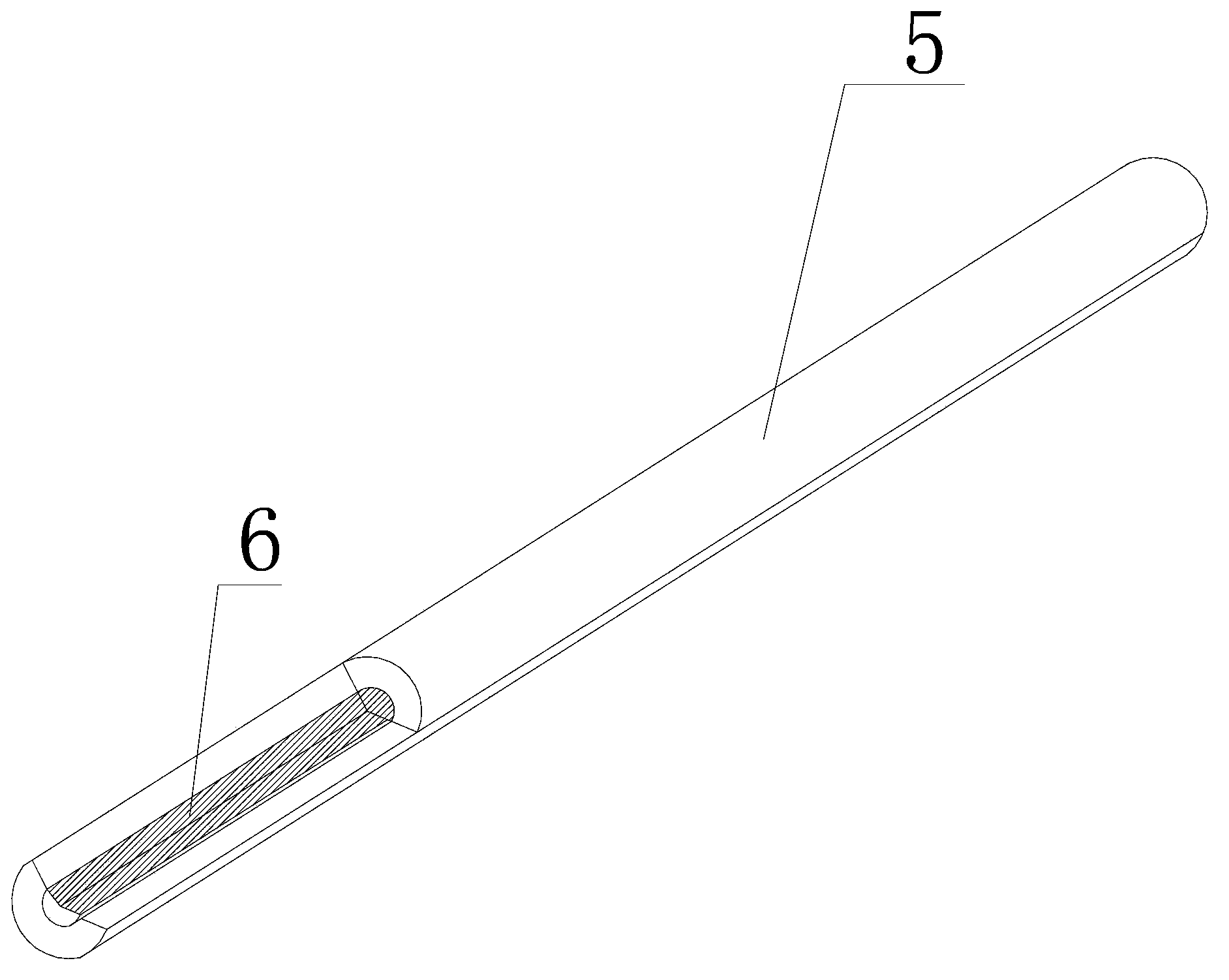

[0033] to combine figure 1 , the structure of the perchlorate electrolysis device is as follows:

[0034] A perchlorate electrolysis device, comprising several electrolyzers 1, the electrolyzers are divided into at least three groups, the electrolyzers in each group are connected in series, and each group of electrolyzers is also connected in series with a circulation barrel 2, the circulation barrel 2 It is distributed in steps, and the circulation barrels 2 are connected through the overflow pipe 3, and the overflow pipe of the circulation barrel 3 at the lowest position is connected to the electrolytic liquid storage tank 4. A circulation barrel and multiple electrolyzers form an internal circulation. Such as figure 1 , the electrolyzers are divided into three groups, each group contains three electrolyzers and a circulation barrel.

[0035] The corresponding perchlorate electrolysis process is: continuously inject the chlorate electrolyte solution with a concentration o...

Embodiment 2

[0039] to combine Figure 1 to Figure 3 , the structure of the perchlorate electrolysis device is as follows:

[0040]A kind of perchlorate electrolysis device, comprises several electrolyzers 1, and electrolyzer is divided into four groups, and the electrolyzer in each group is connected in series, and described each group of electrolyzers is also connected in series with a circulation barrel 2, and circulation barrel 2 is Ladder distribution, the circulation barrels 2 are connected through the overflow pipe 3, and the overflow pipe of the circulation barrel 3 at the lowest position is connected to the electrolytic liquid storage tank 4. A circulation barrel and multiple electrolyzers form an internal circulation. The assembly of the electrolysis device can be as follows: 12 electrolytic cells are divided into four groups, each group is composed of three electrolytic cells and a circulation barrel in series, the number of circulation barrels is large, the number of circulati...

Embodiment 3

[0048] combine Figure 1 to Figure 5 , the structure of the perchlorate electrolysis device is as follows:

[0049] A perchlorate electrolysis device, comprising several electrolyzers 1, the electrolyzers are divided into five groups, the electrolyzers in each group are connected in series, and each group of electrolyzers is also connected in series with a circulation barrel 2, and the circulation barrel 2 is Ladder distribution, the circulation barrels 2 are connected through the overflow pipe 3, and the overflow pipe of the circulation barrel 3 at the lowest position is connected to the electrolytic liquid storage tank 4. A circulation barrel and multiple electrolyzers form an internal circulation. The assembly of the electrolysis device can be as follows: 20 electrolytic cells are divided into five groups, each group is composed of four electrolytic cells and a circulation barrel in series, the number of circulation barrels is large, the number of circulation stages of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com