Gamma-3-hexenyl-gamma-butyrolactone synthesis method

A synthetic method and technology of butyrolactone, which is applied in the direction of organic chemistry, can solve the problems of inconvenient source of raw materials and low yield, and achieve the effects of low production cost, easy operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

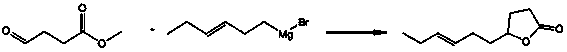

Image

Examples

Embodiment 1

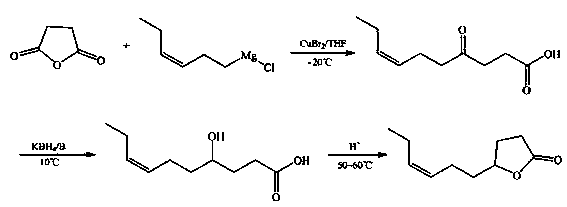

[0028] A kind of synthetic method of gamma-3-hexenyl-gamma-butyrolactone, specifically comprises the steps:

[0029] (1), Synthesis of 4-oxo-7-decenoic acid intermediate

[0030] In the reactor, add 100g (1.0mol) of succinic anhydride, 11g (0.05mol) of copper bromide and 600ml of tetrahydrofuran to obtain a mixed solution, and cool to -20°C;

[0031] Keep the temperature at -20°C, add a solution consisting of 172g (1.2mol) of 1-chloro-cis-3-hexene magnesium and 200ml tetrahydrofuran dropwise into the above mixture within 2 hours, and continue to control the temperature at - 20°C, carry out Grignard reaction for 2 hours, add 1N hydrochloric acid to the obtained reaction solution to adjust the pH=2, then filter, the obtained filtrate is extracted with chloroform, and the obtained organic layer is sequentially washed with a 10% mass percent concentration of sodium bisulfite aqueous solution 1. After washing with saturated brine, dry with anhydrous sodium sulfate, and distill the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com