Low-energy-consumption urea production technology and system adopting CO2 stripping method

A stripping, low-energy-consumption technology, applied in the low-energy CO2 stripping urea process and system field, can solve the problems of low-pressure steam such as low grade, difficult to use, and low efficiency, and achieve simple equipment transformation, increase production capacity, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

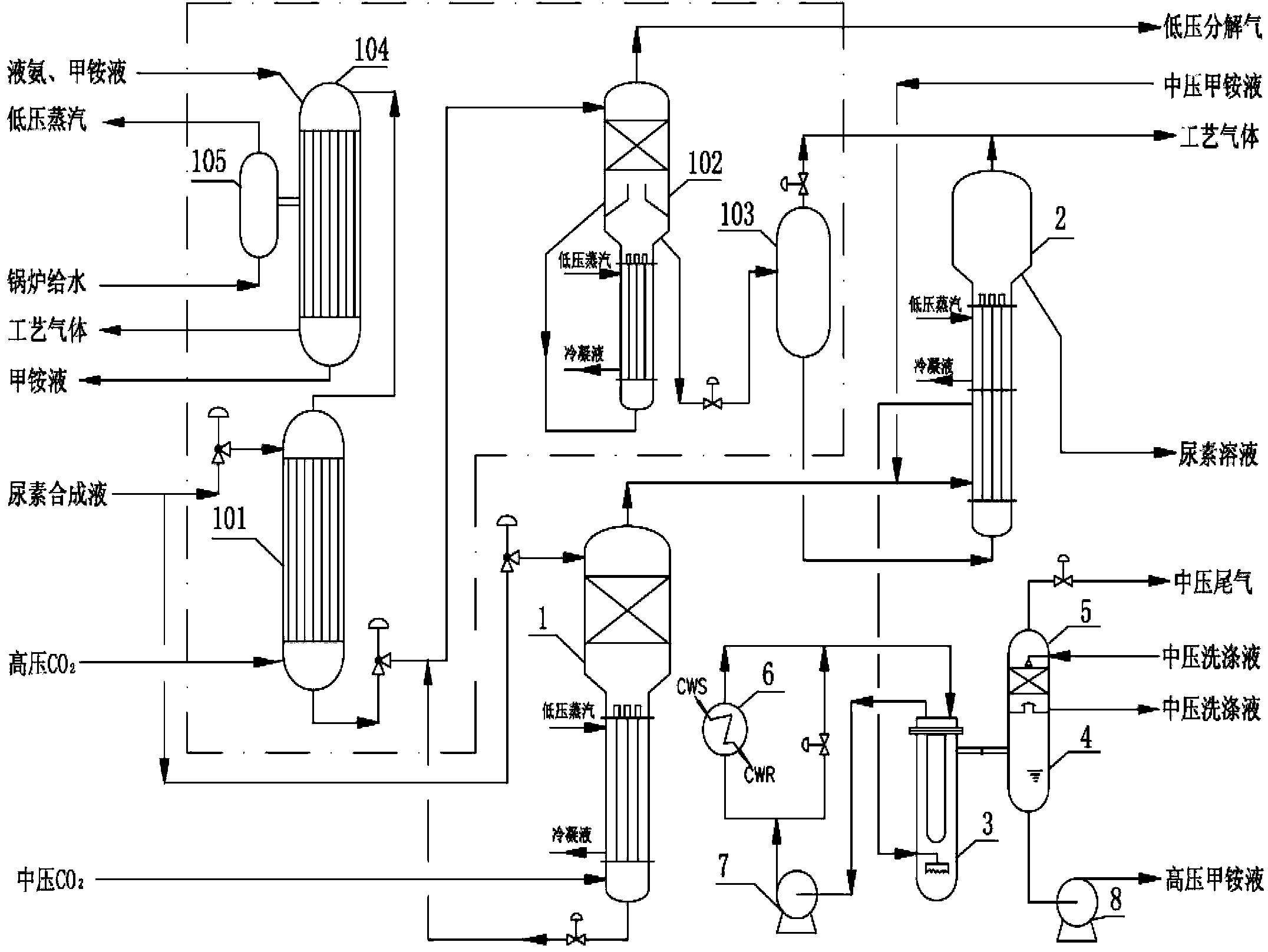

[0028] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0029] refer to figure 1 , low energy CO 2 The stripping urea system includes a high-pressure decomposition recovery system, which includes sequentially connected high-pressure CO 2 Stripper 101, low-pressure decomposition tower 102 and flash tank 103, wherein high-pressure CO 2 The stripping gas outlet of stripper 101 is connected with high-pressure methylammonium condenser 104, and described high-pressure methylammonium condenser 104 is equipped with low-pressure steam bag 105. The medium-pressure decomposition recovery system is connected in parallel with the high-pressure decomposition recovery system, and the medium-pressure decomposition system includes medium-pressure CO 2 Stripper 1, the medium pressure CO 2 The urea stripping liquid outlet of the stripping tower 1 is connected with the urea stripping liquid inlet of the low-pressure decomposition tower 102. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com