Method for treating and recycling waste water in anthranilic acid production technology

A technology for the production process of anthranilic acid, which is applied in the field of treatment and recycling of anthranilic acid production process wastewater, and can solve the problem of wasting phthalimide, large consumption of ethyl acetate, and inability to realize o-amino benzoic acid Recycling of benzoic acid and phthalimide, etc., to achieve the effect of recycling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

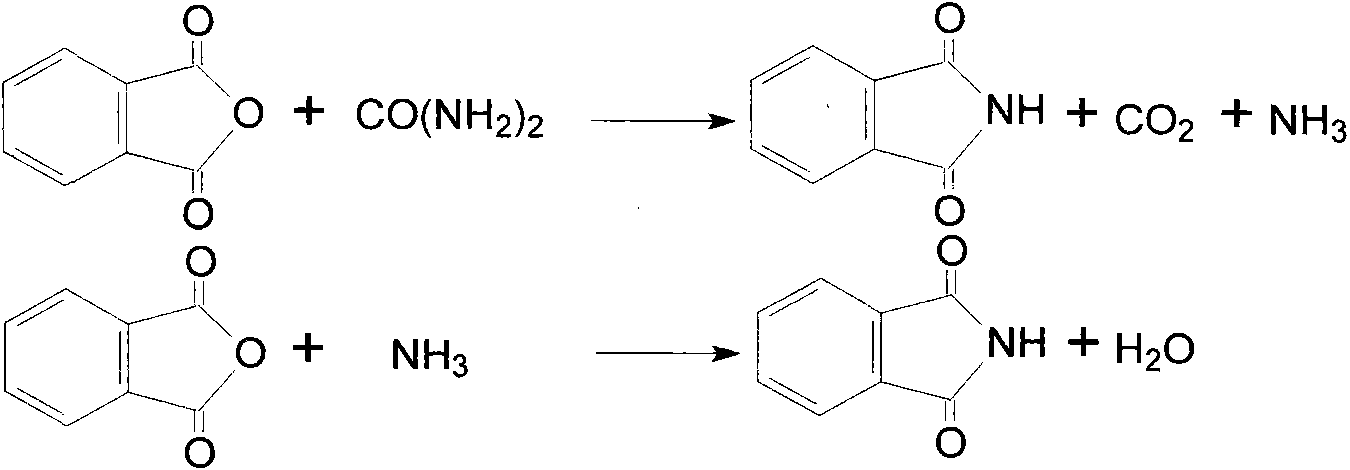

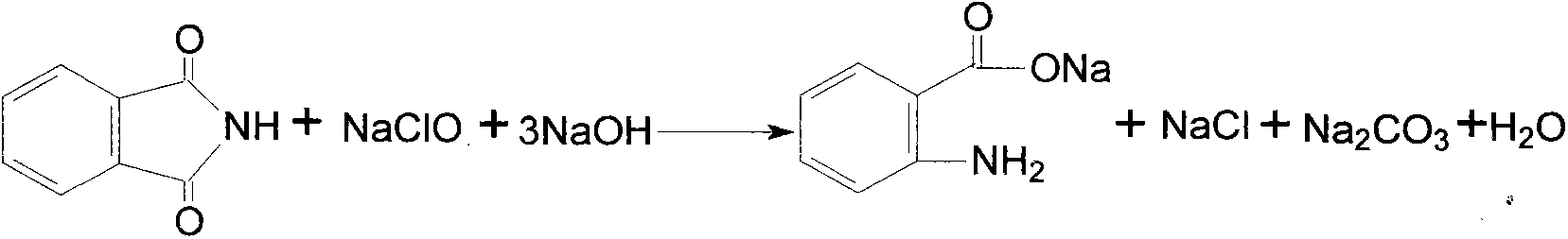

Method used

Image

Examples

Embodiment 1

[0030] Pack 20mL (about 15g, dry weight) of NDA150 resin and ZH01 resin into two adsorption columns (Φ20×250mm) with insulation jackets respectively.

[0031] Get 1000mL of reddish-brown process wastewater in the production of anthranilic acid and filter it, add 0.5ml of 1% sodium hydroxide solution dropwise, the pH is 7.92, and the upper column liquid COD Cr The content of anthranilic acid is 24170mg / L, the content of anthranilic acid is 6160mg / L, and the content of phthalimide is 7960mg / L. At 35±5℃, 640ml of column liquid is passed through the ZH01 resin column at a flow rate of 40mL / h. Grade effluent is light yellow, phthalimide content is 12.2mg / L, phthalimide content is 6014mg / L, COD Cr Reduced to 13990mg / L, after adding 0.5ml of 1% dilute hydrochloric acid dropwise, the pH was 5.08, and at 35±5°C, 400ml of the upper column liquid was passed through the NDA150 resin column at a flow rate of 40mL / h, and the secondary adsorption water was colorless, adjacent Phthalimide un...

Embodiment 2

[0035] Pack 200mL (about 150g, dry weight) of NDA150 resin and 300mL (about 225g, dry weight) of ZH01 resin into two adsorption columns (Φ35×500mm) with insulation jackets respectively.

[0036] Get 10L reddish-brown process wastewater in the production of anthranilic acid and filter, then add dropwise 5ml of 1% sodium hydroxide solution, the pH is 8.04, and the upper column liquid COD Cr The content of anthranilic acid is 23960mg / L, the content of anthranilic acid is 6210mg / L, and the content of phthalimide is 8026mg / L. At 5±5℃, 6400ml of column liquid is passed through the ZH01 resin column at a flow rate of 200mL / h. The grade effluent is pale yellow, the content of phthalimide is 14.7mg / L, the content of anthranilic acid is 6102mg / L, COD Cr Reduced to 14160mg / L, after adding 5ml of 1% dilute hydrochloric acid dropwise, the pH was 4.98, and 6400ml of the upper column liquid was passed through the NDA150 resin column at a flow rate of 200mL / h at 5±5°C, and the secondary adsorpt...

Embodiment 3

[0040] Change the ZH01 resin in Examples 1 and 2 in Examples 1 and 2 into FZH11, ZH124, ZH33 respectively, and change NDA150 resin into JX101 resin, CHA111 resin, AmberLiteXAD-7, XAD-4, XAD-2 resin respectively, Other operating conditions remained unchanged, and the results were basically the same except that the volume of each batch and the amount of recovery were changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com