Semi-automatic electronic block instrument and working method of block instrument

A blocking machine, semi-automatic technology, applied in railway car body parts, railway signals and safety, interlocking devices between switches and signals, etc., can solve the problems of large maintenance workload, poor anti-interference ability, and large workload, etc. Achieve the effect of convenient upgrade and transformation, strong anti-interference ability and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

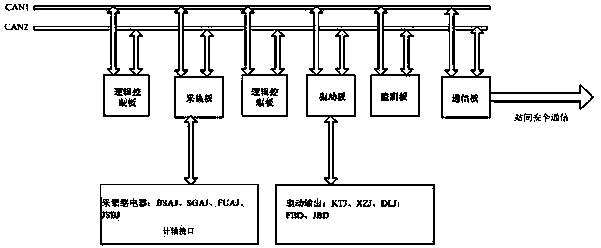

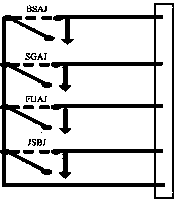

[0038] Such as figure 1 As shown, the present invention is connected by a CAN bus by a communication board, an acquisition board, a driver board, a monitoring board, a communication board and two logic control boards. Such as figure 2 As shown, each logic control board consists of two parallel CPU , a comparator and a fault detection module. The two logic control boards are controlled by a switch, and the two logic control boards form a two-by-two redundant system, which greatly improves the system reliability. The monitoring board communicates with the microcomputer monitoring system, and uploads the working status and alarm information of the equipment to the microcomputer monitoring system, so as to achieve real-time maintenance of the system and accurate fault location.

[0039] image 3 It is a schematic diagram of the acquisition interface circuit. The acquisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com