Battery pack suspension mechanism for pure electric vehicles

A pure electric vehicle and suspension mechanism technology, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of the service life of the vehicle battery pack, low power, long charging time, etc., to improve stability and work reliability High performance, small size, and the effect of ensuring horizontal position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

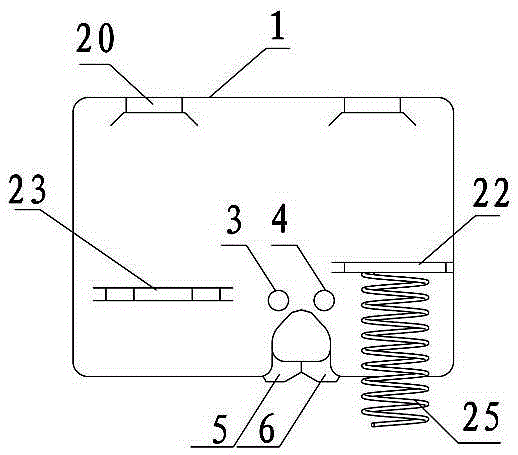

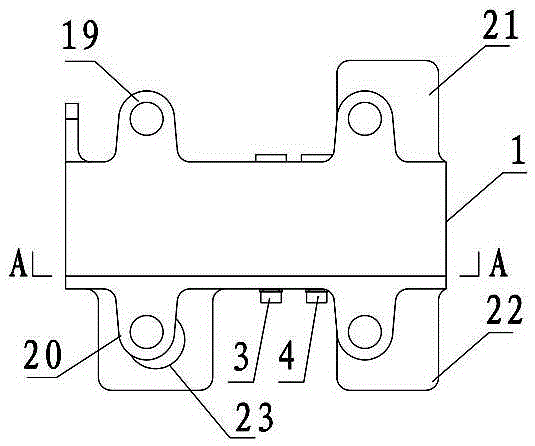

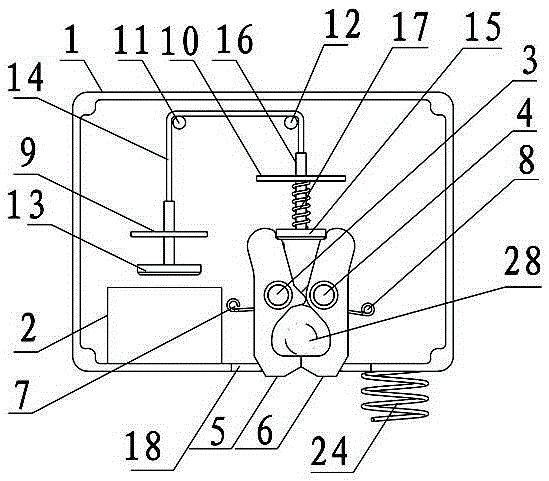

[0019] Such as Figure 1-5 As shown, the battery pack suspension mechanism for pure electric vehicles of the present invention includes a box body 1; an electromagnet 2 is fixed at the inner bottom of the box body 1, and is positioned at a horizontal interval on the box wall on one side of the electromagnet 2. Two rotating shafts 3, 4 are fixed, and a pair of hooks 5, 6 are hinged on the two rotating shafts 3, 4, and the two hooks 5, 6 connect with the box wall through the torsion springs 7, 8 set on the two rotating shafts 3, 4 respectively. connection, the top and middle of each hook 5,6 are correspondingly provided with a stop groove 26 and a flange 27; the position-limiting guide plate 9, 10. Guide posts 11 and 12 are respectively fixed on the box walls above the two limit guide plates 9 and 10; an armature 13 is arranged directly above the electromagnet 2, and the armature handle slides through and is located above the electromagnet 2. The limit guide plate 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com