Beveling machine

A technology of beveling machine and telescopic mechanism, which is applied in the field of beveling machine, can solve the problems of large tank body, difficult processing, high technical proficiency requirements, etc., and achieve the effect of small size and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

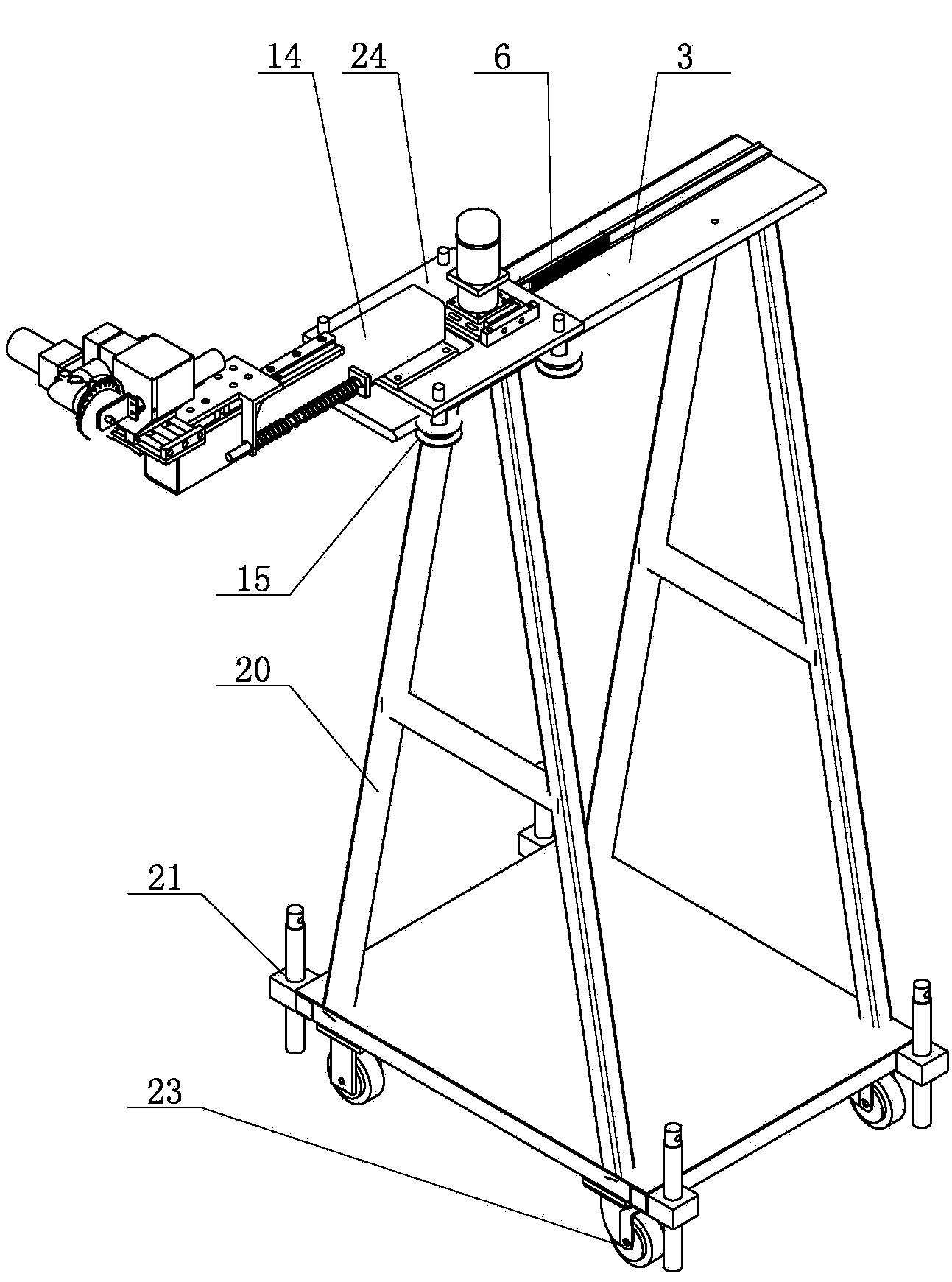

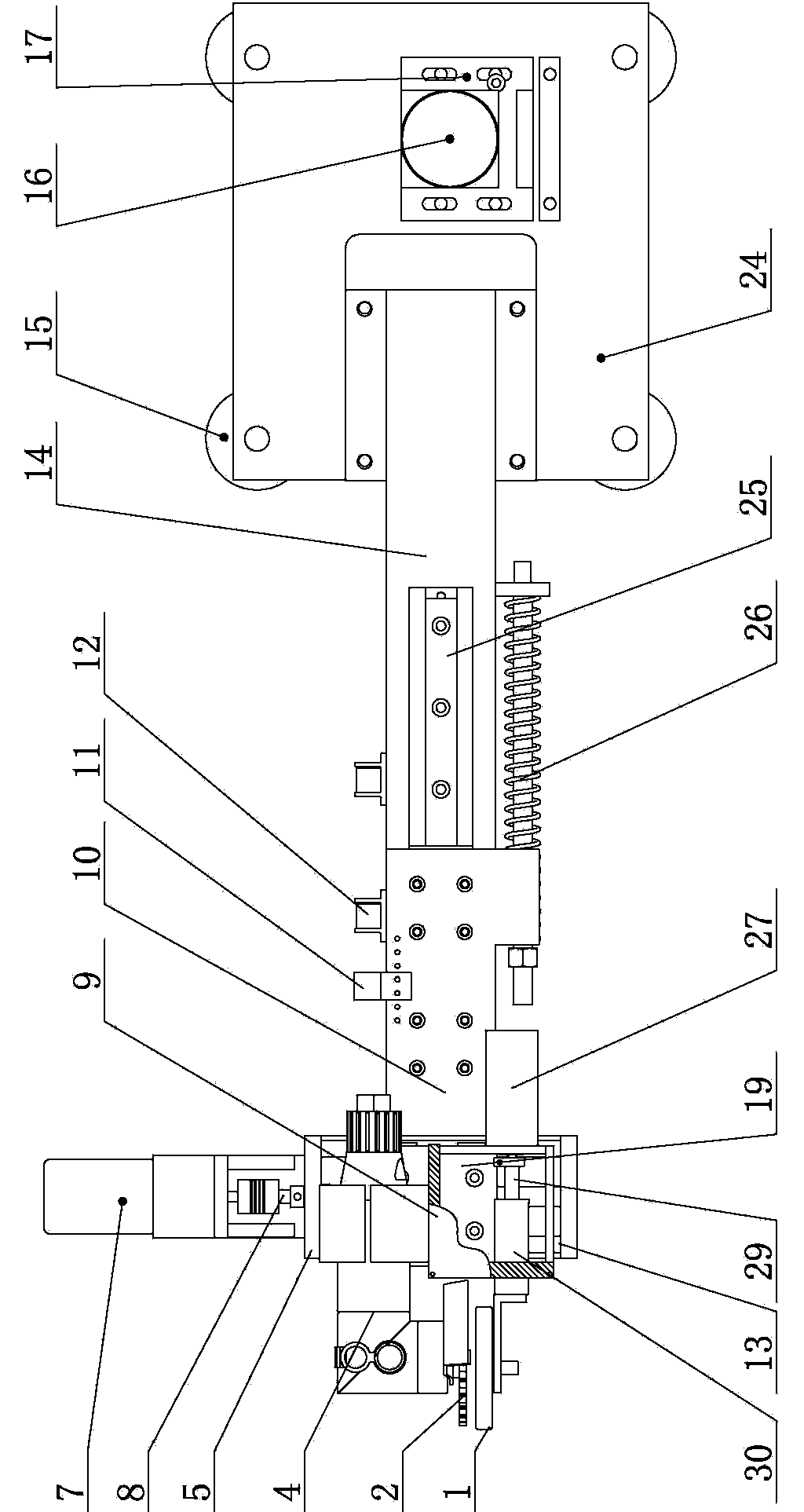

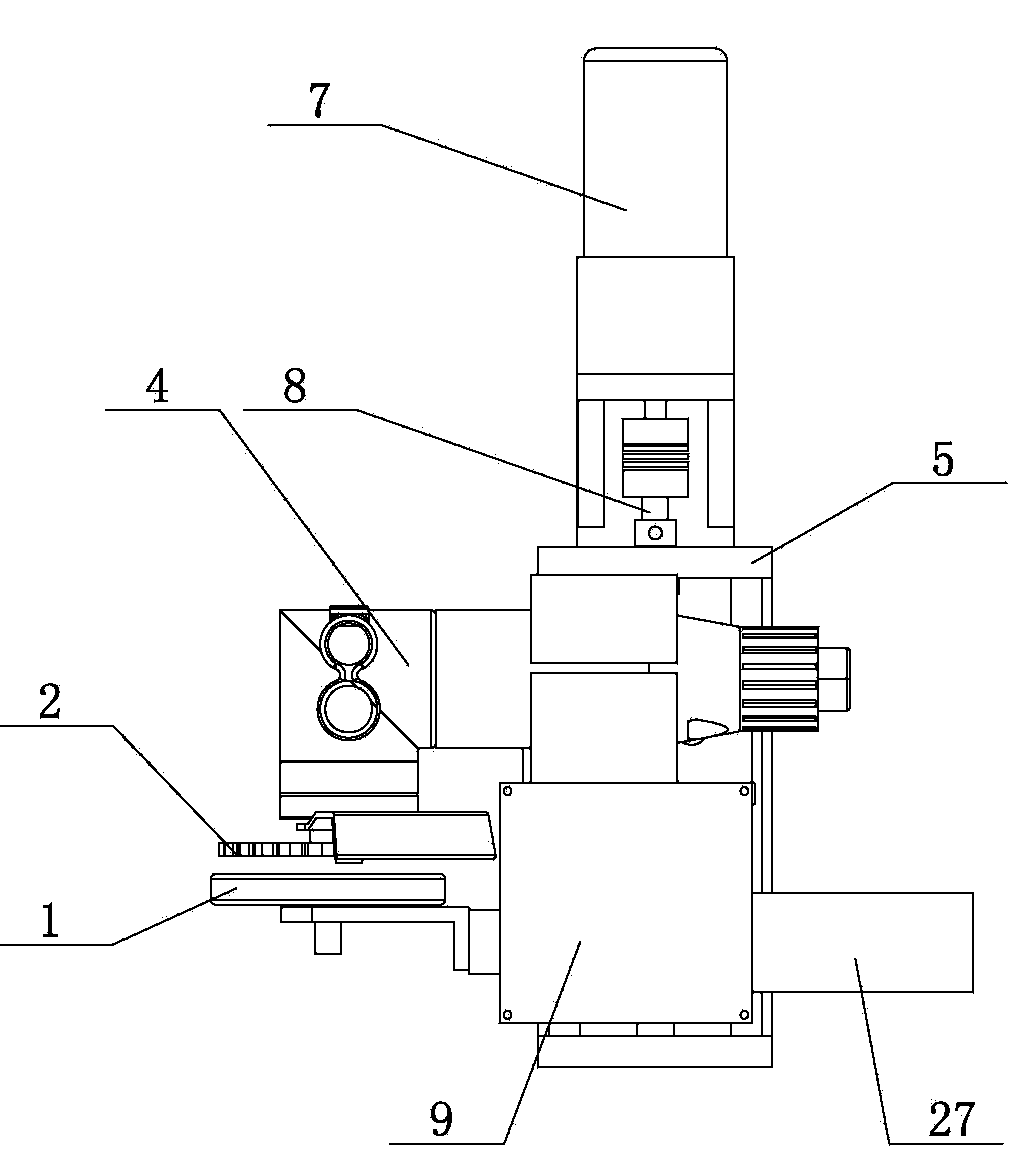

[0009] Such as figure 1 As shown, the beveling machine of the present invention includes a bracket 20 . A base is installed on the support 20, and the sliding frame 10 is installed on the base. The carriage 10 can slide back and forth along the base. Connecting seat is installed on the sliding frame 10, and cutting knife and bearing 9 are installed on the connecting seat. Telescopic mechanism is installed on the bearing 9, profiling wheel 1 is installed on the linear moving parts of telescopic mechanism, and profiling wheel 1 is arranged side by side with cutter, to control the depth of cut of cutter. A spring 26 is installed between the sliding frame 10 and the base, and the spring 26 provides a reset force for the sliding frame 10 to ensure that the cutter and the profiling wheel 1 apply pressure to the tank body all the time.

[0010] working principle:

[0011] First erect the two ends of the tank body on the rotating mechanism, so that the tank body 28 can rotate arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com