Repairing process applicable to polluted clay

A technology of clay and technology, applied in the field of restoration technology, can solve the problems of difficult screening, poor treatment effect and low treatment efficiency, and achieve the effect of enhancing treatment effect, improving treatment effect and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

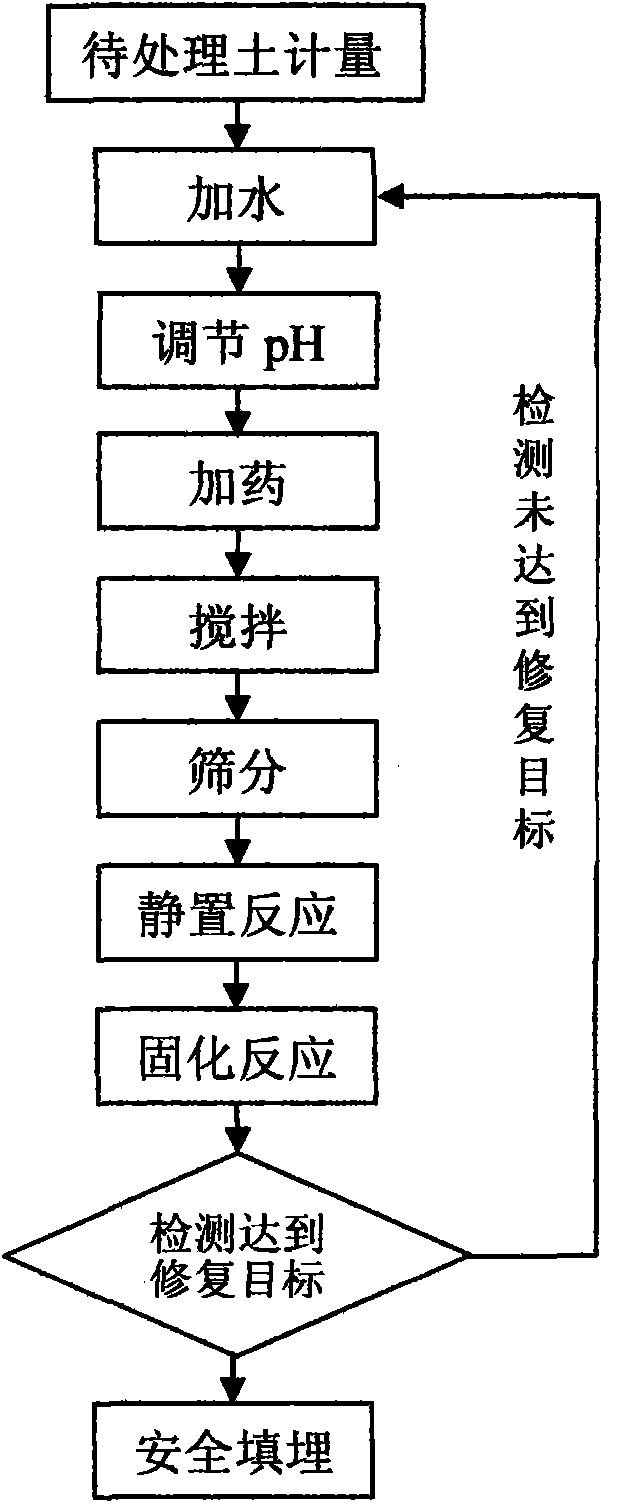

[0018] Such as figure 1 Shown, the present invention is applicable to the restoration process of polluted clay, and it comprises the following steps:

[0019] 1) Measurement of the soil to be treated: Load the contaminated clay to be treated into a dump truck, weigh it with a floor scale, transport it to the treatment site after weighing, and dispose of it in separate piles. Each pile of contaminated clay to be treated weighs 50 tons;

[0020] 2) adding water: adding enough water to the polluted clay measured in step 1) to ensure that the soil moisture content is at 20% to 30%;

[0021] 3) Adjusting PH: adding acid or alkali to the contaminated clay treated in step 2) for adjustment, adjusting to the acid-base condition required for the reaction between the stabilizing agent and the pollutant, and testing with pH test paper;

[0022] 4) Dosing (stabilization): adding a stabilizing agent to the contaminated clay treated in step 3), the dosage is 3%-5%;

[0023] 5) Stirring: S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com