Controllable water-paint-coated furniture microwave drying device

A technology of microwave drying and water-based paint, which is applied to devices, coatings, and pretreatment surfaces for surface coating. It can solve problems such as short service life, furniture cracking, air bubbles, etc., to prevent microwave leakage and achieve real-time accuracy. The effect of controlling and protecting personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

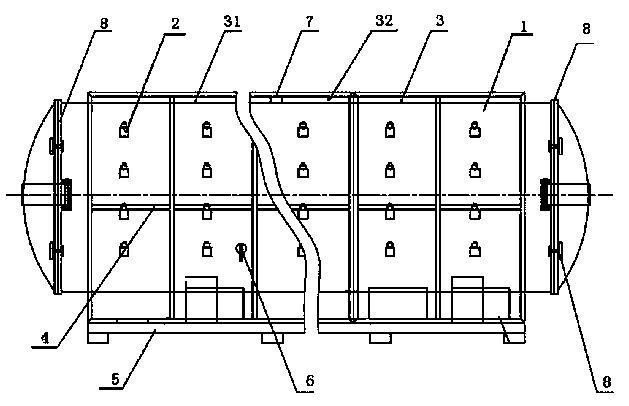

[0024] A controllable microwave drying water-based paint coating furniture equipment, including: a box body 1, a microwave emission device 2, a sensing system, an exhaust system 4, a transmission system 5, a travel limiter 6, a smoke alarm 7 and a sealing The tightening device 8 and the PLC controller; the sensing system includes: a temperature sensor 31 and a humidity sensor 32; the transmission system uses materials that do not absorb microwaves.

[0025] The connections of the above components are as follows:

[0026] The microwave emission system 2 is located on both sides and the top of the box; the temperature sensor and the humidity sensor are located on both sides and / or the top of the box; the exhaust system is located on the top of the box; the transmission system runs through the entire box , the part located in the box is distributed under the microwave; the stroke limiter is located at both ends of the box; the PLC controller is respectively connected with the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com