Zero emission steam generation process

A steam generator and steam technology, applied in steam generation method, steam generation, earthwork drilling and other directions, can solve the problems of reducing in-situ reservoir temperature and oil recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

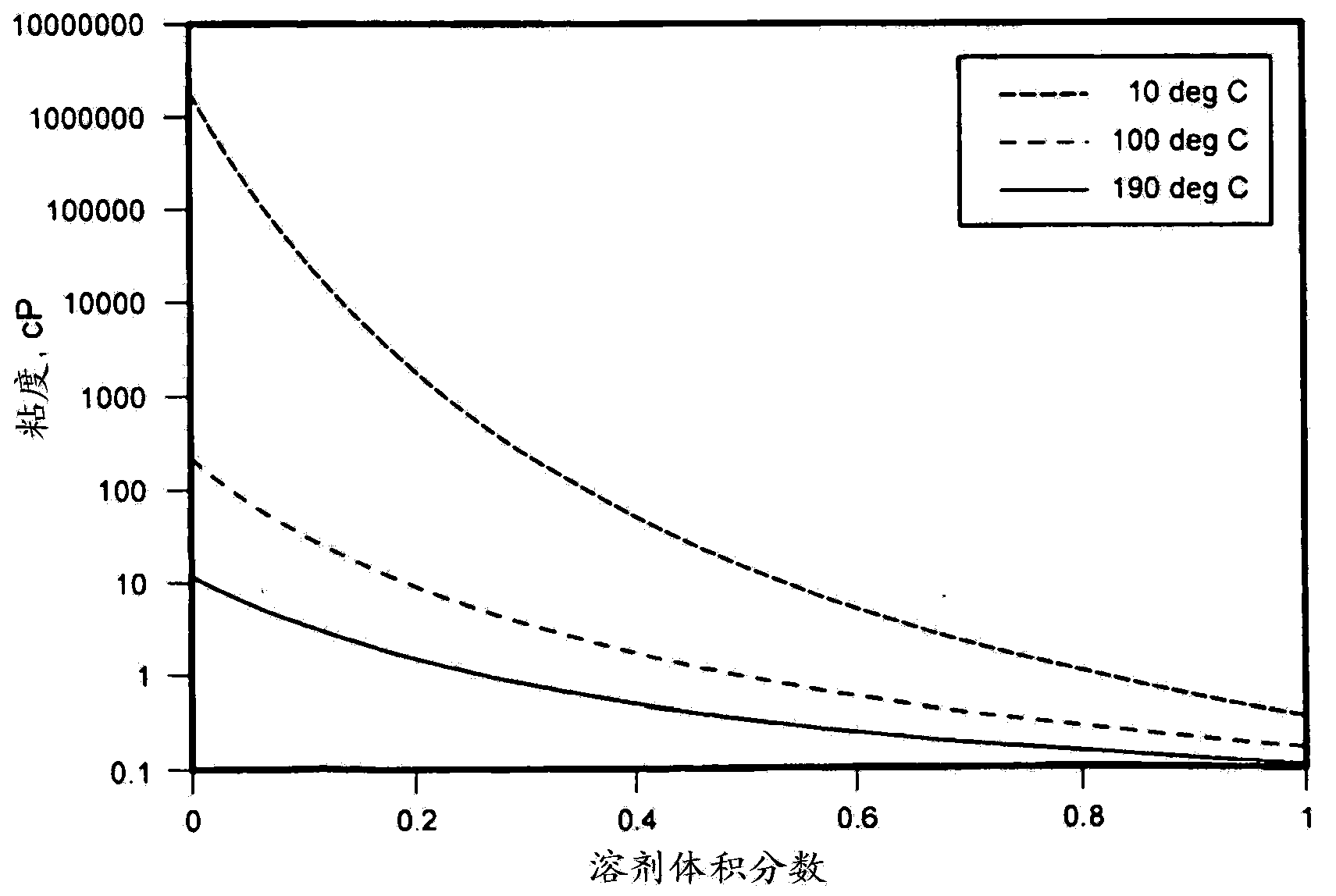

Image

Examples

no. 4 approach

[0085] A fourth embodiment of the present invention, allows the use of heavier fuels such as distillate or heavy fuel oil to produce larger fractions of carbon dioxide as high as 35%. In this embodiment, the mass fraction of carbon dioxide is adjusted as a parameter of the reservoir and oil to maximize recovery.

no. 5 approach

[0086] A fifth embodiment of the present invention allows for the addition of lighter hydrocarbons or other compounds to the steam carbon dioxide stream downstream of the steam separator to act as additional solvent for use in hydrocarbon recovery.

[0087] The sixth embodiment of the present invention allows the partial oxidation of fuels, which together with pyrolysis and hydrothermolysis can produce a synthesis gas composed of water, hydrogen, carbon dioxide, and carbon monoxide. The syngas can be injected into oil formations to enable oil recovery and partial upgrading if the injected gas is at a temperature sufficient to enable subterranean gasification of oil (typically above about 300°C).

[0088] A further benefit of injecting water with traces of oil and impurities into the oxyfuel steam generator is the use of those impurities as fuel during the combustion process. In this case, the impurities are incinerated and additional thermal energy is provided for steam genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com