Reciprocating compressor crankshaft reliability optimization design method

A technology of compressor crankshaft and optimization design, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of not considering the change of the crankshaft load, no interaction of the cranks, and simplification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

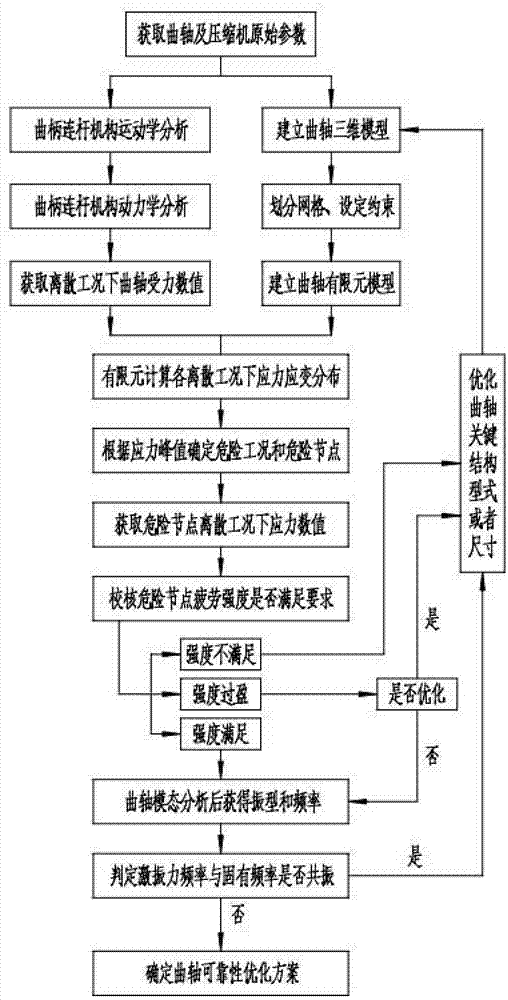

[0067] For ease of understanding, the specific workflow and principles of the present invention are further described below in conjunction with the accompanying drawings:

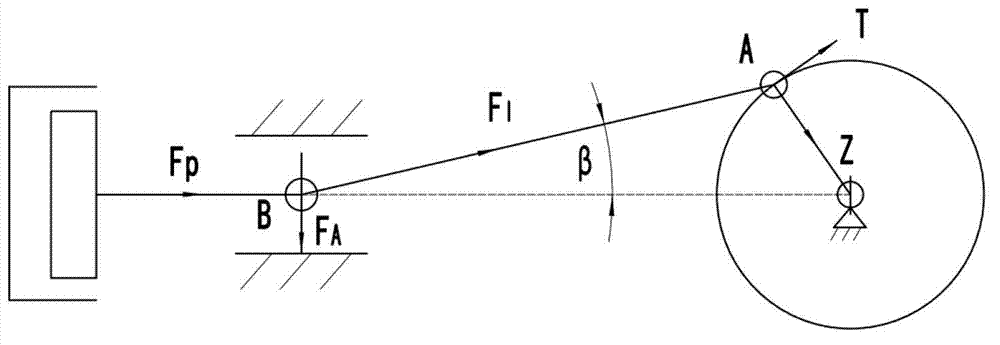

[0068] 1 Dynamic analysis of the crank-link mechanism

[0069] The main content involved in the dynamic analysis of the crank connecting rod mechanism is to analyze the motion law and force of the crank connecting rod mechanism of the compressor, which will provide the basis for the finite element analysis of the crankshaft later.

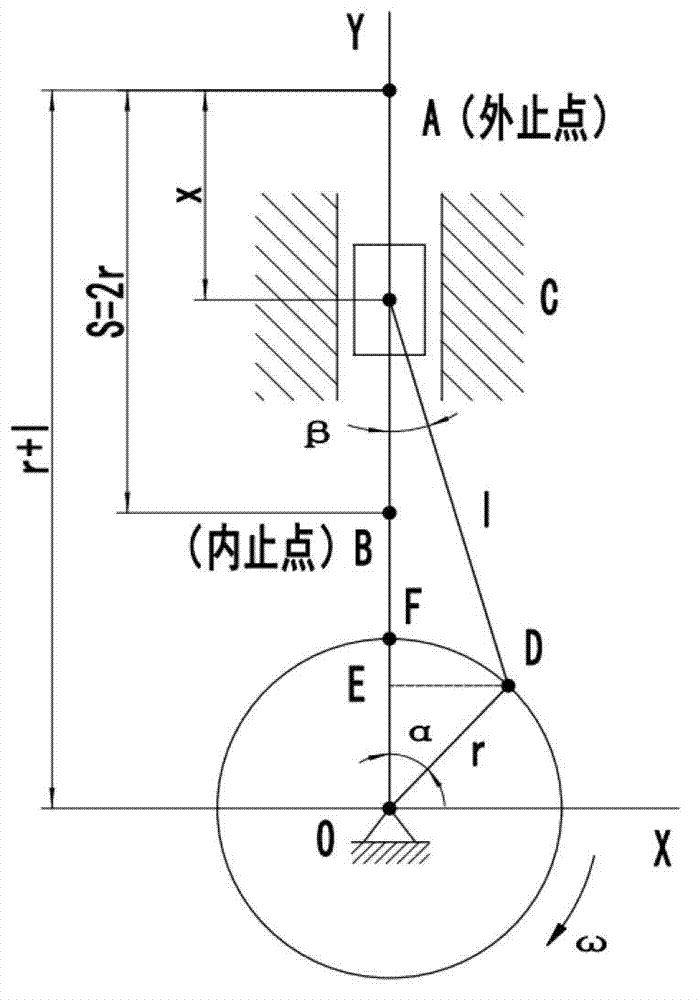

[0070] 1..1 Kinematic relationship of crank linkage mechanism

[0071] The working principle of the reciprocating piston compressor is mainly to convert the rotary motion of the prime mover into the reciprocating motion of the compressor piston by using the crank connecting rod mechanism. When analyzing the work of the crank connecting rod mechanism, in fact, the angular velocity is a variable due to the uneven torque. When studying the torsional vibration of the crankshaft and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com