Device and method for carrying out in-situ testing on transport properties of conductor materials at high temperature and high pressure

A high-temperature, high-pressure, in-situ testing technology, which is applied in the fields of high-pressure science and technology and material science, can solve problems such as inappropriateness and large measurement errors, and achieve the effects of small experimental errors, high success rate, and large sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

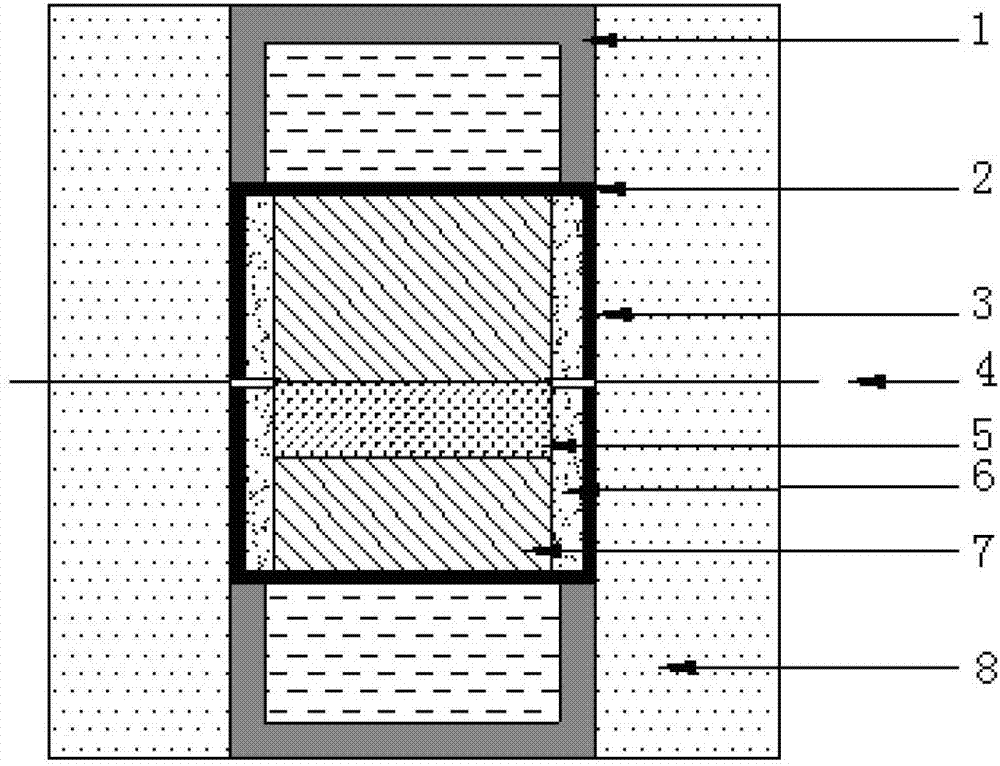

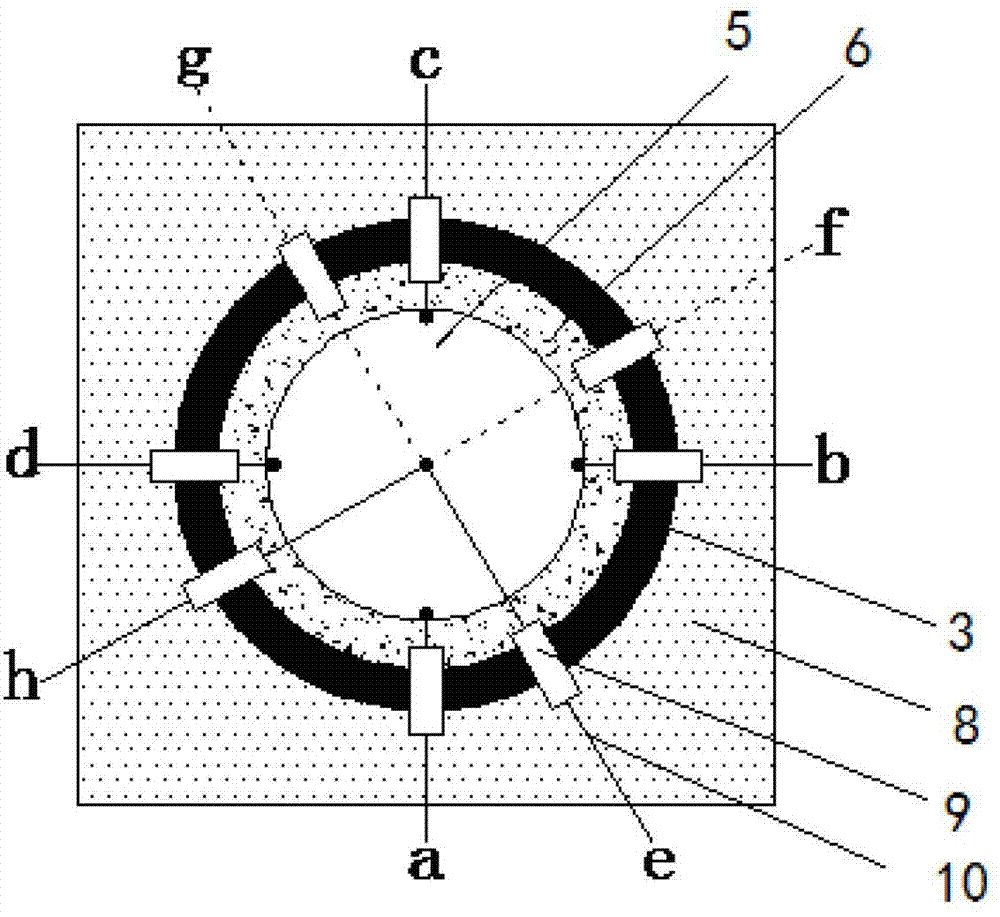

[0030] The structure of the device for in-situ testing of the transport properties of conductor substances under high temperature and high pressure is composed of figure 1 and figure 2 give. exist figure 1 and figure 2 Among them, 1 is a steel cap, 2 is a graphite sheet, 3 is a graphite tube, 4 is a copper wire (a total of 4 copper wires are counted as a, b, c, d), 5 is a sample, 6 is an MgO insulating tube, 7 is MgO insulating sheet, 8 is pyrophyllite block, 9 is ceramic tube, and 10 is thermocouple (two pairs of thermocouples can choose NiCr-NiAl thermocouple, e, h are the positive pole and negative pole of a pair of thermocouple f, g are another positive and negative terminals of a pair of thermocouples).

[0031] according to figure 1 , 2 As shown, the same as the assembly block synthesized by high temperature and high pressure, the side wall of the assembly block is composed of pyrophyllite block 8, graphite tube 3, and MgO insulating tube 6, and the two ends of t...

Embodiment 2

[0033] The assembly block synthesized by high pressure is according to the structure of embodiment 1 (ie figure 1 , 2 structure of the assembly block shown) was assembled and placed in the press. Connect the four side anvils with the DC power supply and the measuring instrument with wires. Set the pressure and temperature, start running, and start heating when the press reaches the set pressure. Wait for the temperature in the center of the cavity to be constant (generally after ten minutes of heating) to start resistivity measurement.

[0034] see figure 2 , current I ab Flow from a to b, and measure the voltage drop V at d and c dc , record the relative resistance value R A =V dc / I ab ; current I bc Flow from b to c, the voltage drop V is measured at a and d ad , record the relative resistance value R B =V ad / I bc . Then the relationship between sample resistivity ρ, sample thickness d and relative resistance value is:

[0035] exp(-πR A d / ρ)+exp(-π( B d / ...

Embodiment 3

[0037] The assembly block synthesized by high pressure is according to the structure of embodiment 1 (ie figure 1 , 2 The structure of the assembled block shown) was assembled and placed in a press in which the upper or lower surface of sample 5 passed through the center of the assembled block. Connect the four side anvils to the instrument for measuring potential difference with wires. After setting the pressure and temperature, start to run. When the press reaches the set pressure, it starts to heat. After heating for ten minutes, wait for the temperature in the center of the cavity to be constant, and start to measure the Seebeck coefficient.

[0038] see figure 2 , respectively measure the potential difference V between the positive poles of the two pairs of thermocouples ef and the potential difference between the negative electrode V hg ;according to the formula V ef =(S NiCr -S) ΔT,V hg =(S NiAl -S) ΔT, simultaneous: S=S NiAl -[V ef( S NiAl -S NiCr ) / (V ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com