Pressurization electric lubricating grease injector

A technology of grease injection machine and driving motor, which is applied in the direction of pressure lubricant, engine lubrication, engine components, etc., and can solve the problems of time-consuming and labor-intensive filling, increased production costs, and repetitive labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

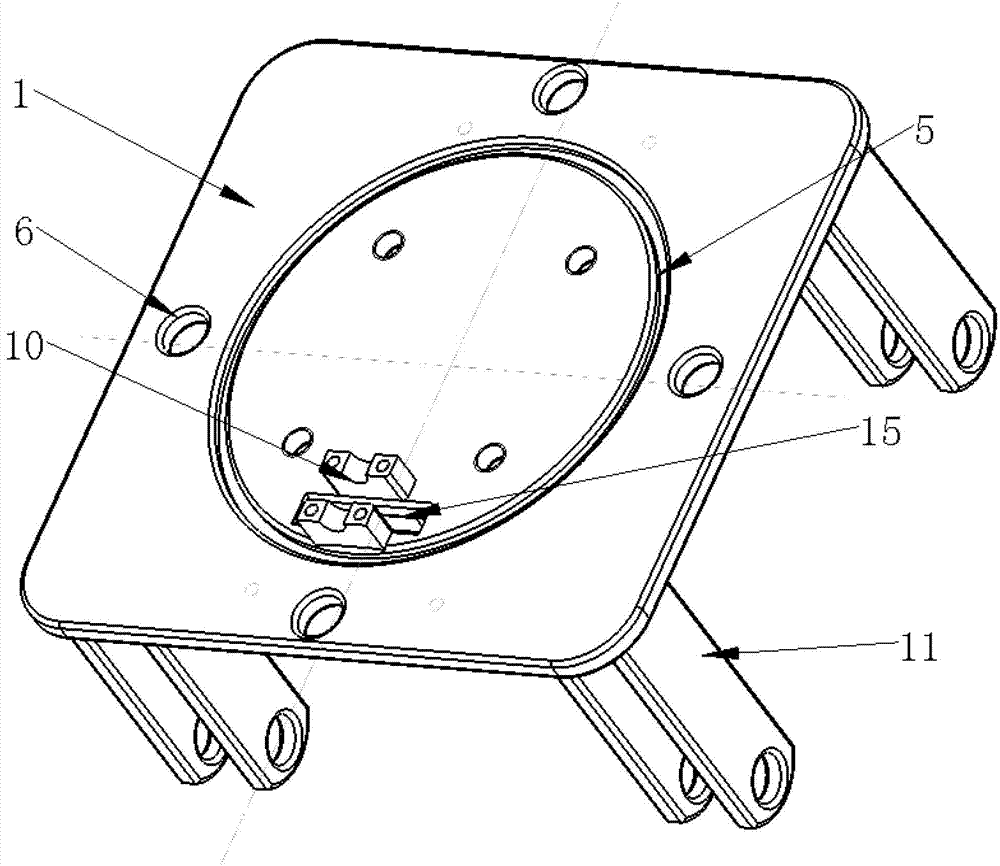

[0029] exist figure 1 Among them, a circular oil cylinder groove 5 and a cylinder fixing bolt hole 6 are processed on the top end surface of the fixed bottom plate 1, and the circular oil cylinder groove 5 and the oil cylinder fixing bolt hole 6 fully guarantee the sealing and connection reliability of the oil cylinder. Oil cylinder 7 is housed in circular oil cylinder groove 5 grooves, is provided with connecting boss 8 and oil cylinder lug 9 on oil cylinder 7 one end, in order to facilitate the assembly with oil cylinder head. Oil cylinder 7 upper end is equipped with oil cylinder cover 2, seals by O type seal ring between oil cylinder cover 2 and oil cylinder 7, thus has guaranteed the tightness of oil cylinder and can also make oiling machine oil injection pressure bigger and safer. In the circular space formed in the middle of the circular oil cylinder groove 5, there are respectively provided with fixing bolt holes 6 for fixing the jack, and two driven shaft brackets 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com