Air cooling tower X-shaped pillar construction method

A construction method and air-cooling tower technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as no longer suitable for local conditions and large loss of circulating water, so as to avoid deformation or even collapse accidents, improve quality, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

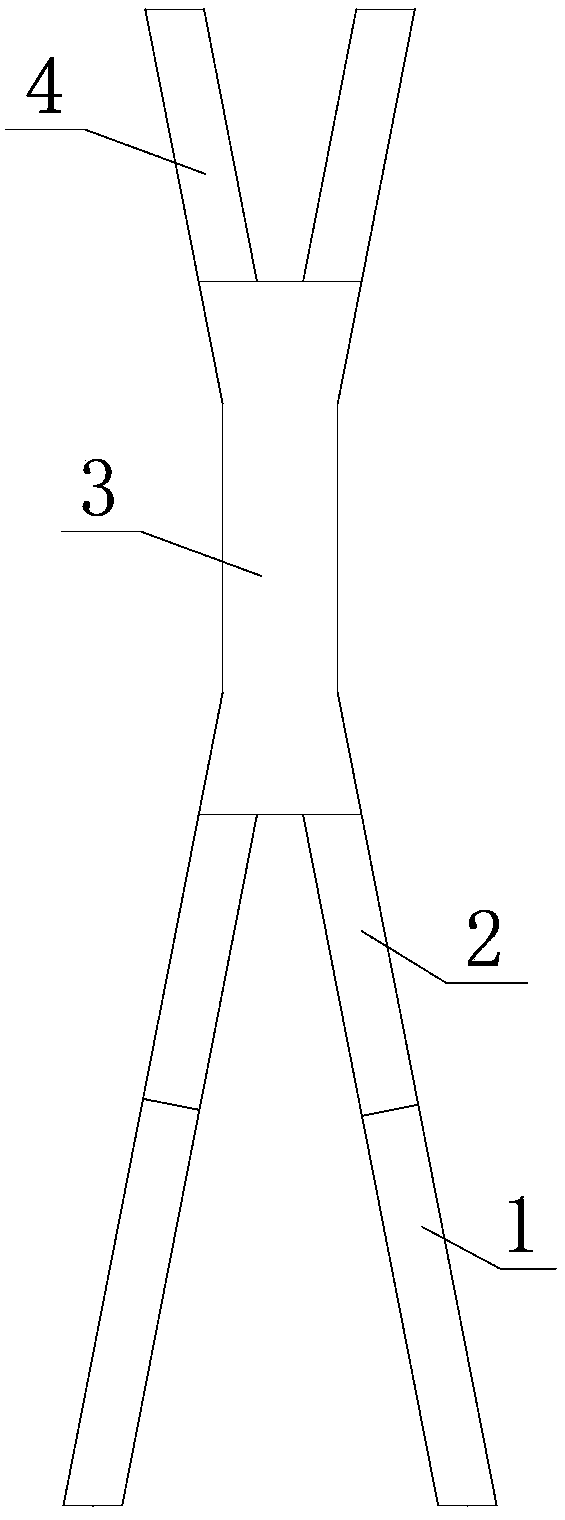

[0025] The X-shaped column construction method of the air cooling tower of the present invention comprises the following steps:

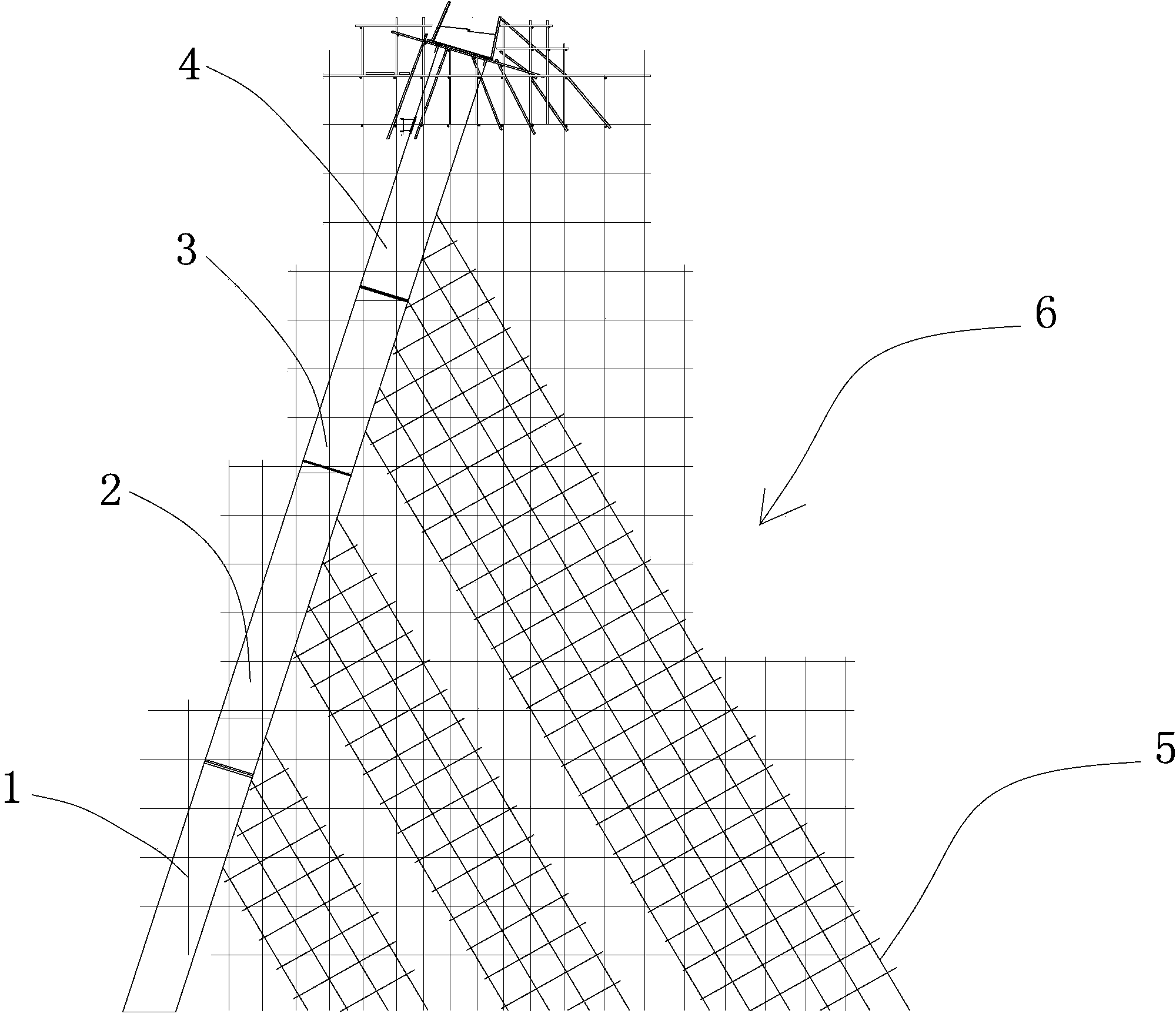

[0026] a. Calculate the construction load during the construction of the X-column of the air-cooling tower according to the construction drawings of the X-column of the air-cooling tower, and calculate the erection density of the scaffold 6 according to the construction load;

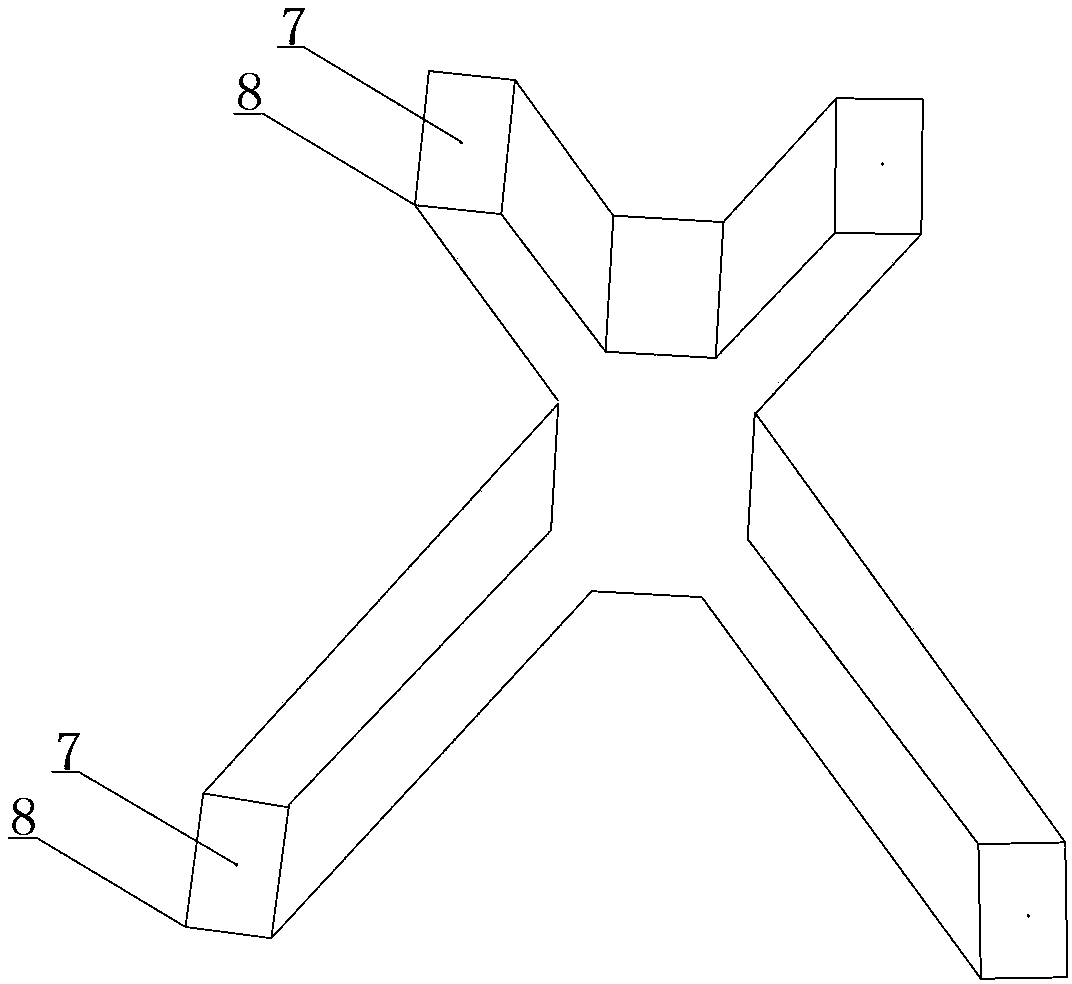

[0027] b. Use computer software to draw a three-dimensional diagram of the X-shaped column of the air-cooling tower in proportion, project the central control point 7 and the control point 8 at the corner of the air-cooling tower X-shaped column on the upper and lower ends of the air-cooling tower to the annular foundation 9, and use the software to mark output data;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com