Low-emissivity coated laminated skylight glass

A low-emissivity coating, skylight glass technology, applied in glass/slag layered products, layered products, chemical instruments and methods, etc. Achieve the effect of saving production cost, improving stability and improving thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0053] Embodiment 5 adopts such as Figure 5 The film structure of the single-silver low-emissivity coated glass shown is as follows from the glass substrate 1 upwards: lower dielectric layer 301 / first lower barrier layer 302 / first infrared reflection layer 303 / first upper barrier layer 304 / upper dielectric Layer 313 / protective layer 314. Wherein, the first lower barrier layer 302 is divided into a first sublayer 3021 of the first lower barrier layer and a second sublayer 3022 of the first lower barrier layer.

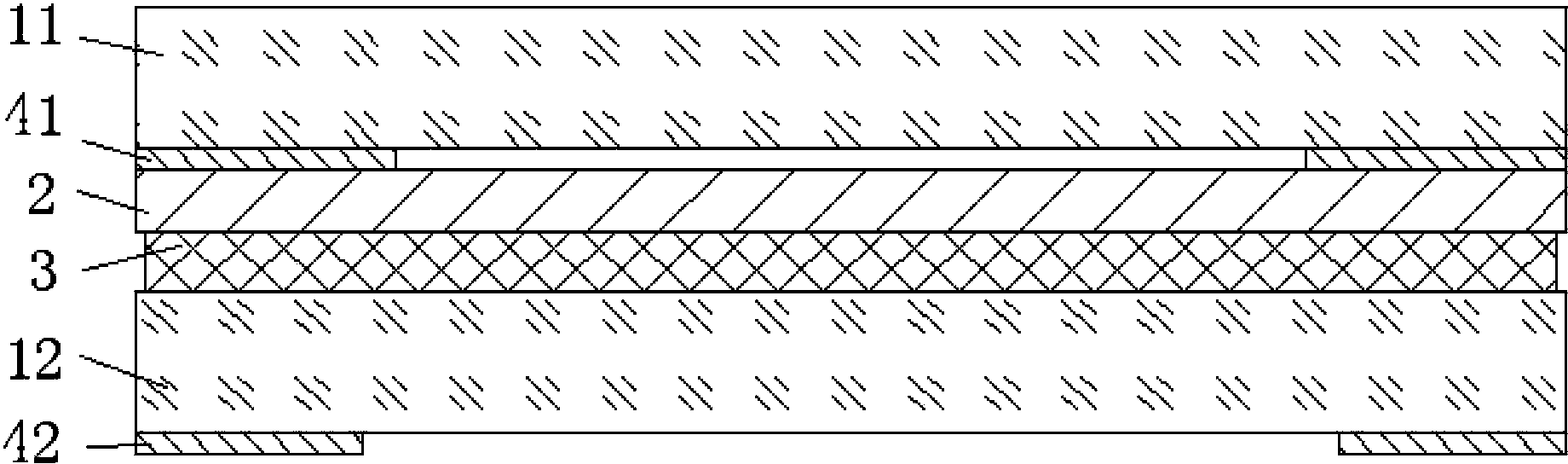

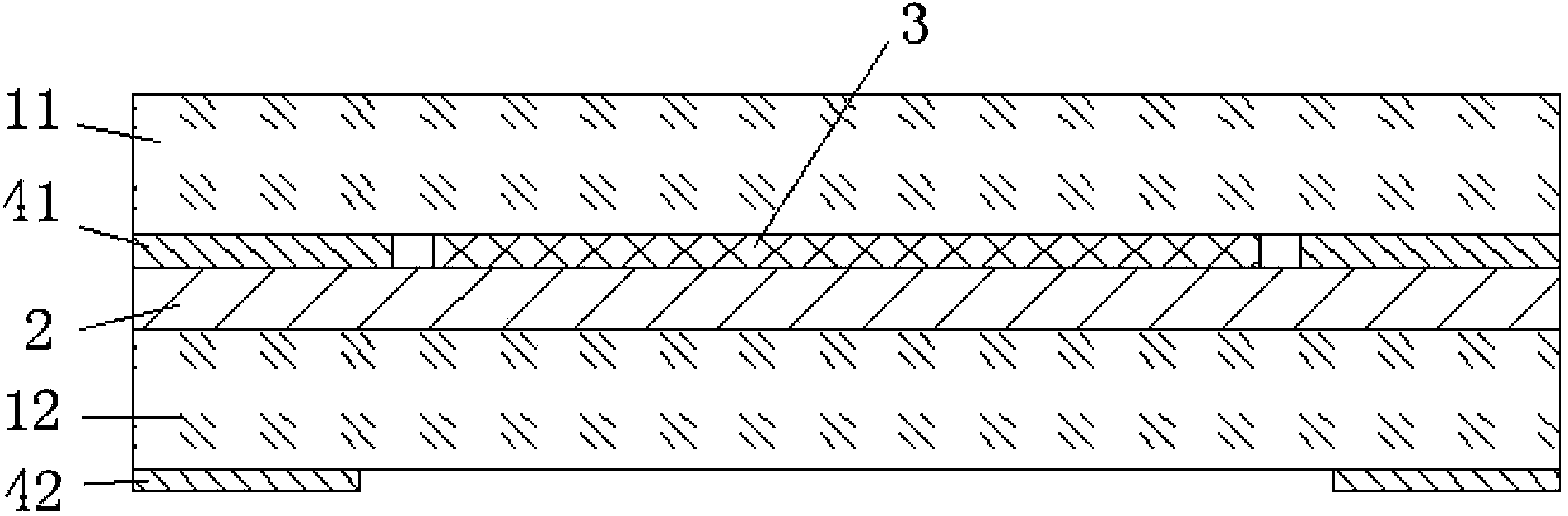

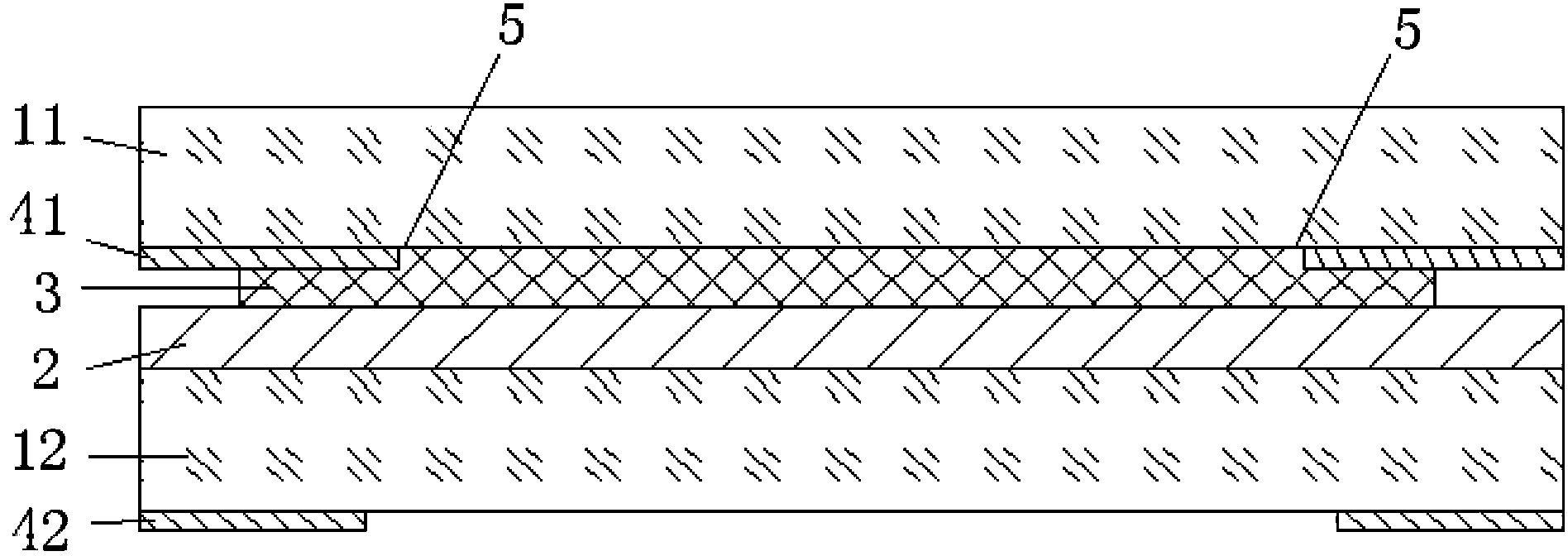

[0054] Such as image 3 As shown, the first glass substrate 11 is made of transparent float glass with a thickness of 2.0 mm. After cutting, edging, washing, drying, screen printing, and sintering, it is washed and dried again by a coating washing machine, and then the Chinese patent 200920077797 is adopted. .X’s shielding technology shields the first ink edge 41 set on the surface of the first glass substrate 11, and finally the first glass substrate 11 and the shie...

Embodiment 6

[0061] Embodiment 6 adopts such as Image 6 The three-silver low-emissivity coated glass shown has a film system structure from the glass substrate 1 upwards: lower dielectric layer 301 / first lower barrier layer 302 / first infrared reflection layer 303 / first upper barrier layer 304 / first Dielectric layer 305 / second lower barrier layer 306 / second infrared reflective layer 307 / second upper barrier layer 308 / second dielectric layer 309 / third lower barrier layer 310 / third infrared reflective layer 311 / third upper barrier layer 312 / upper dielectric layer 313 / protective layer 314. Wherein, the first lower barrier layer 302 is divided into the first sublayer 3021 of the first lower barrier layer and the second sublayer 3022 of the first lower barrier layer, and the second lower barrier layer 306 is divided into the first sublayer 3022 of the second lower barrier layer. The sublayer 3061 and the second sublayer 3062 of the second lower barrier layer, the third lower barrier layer 310 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com