Method for forging and sleeve packaging of ultra-large type nickel-base superalloy turbine disc

A technology of nickel-based superalloys and superalloys, which is used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can meet the requirements of the forging process for the temperature control accuracy of the forgings, and achieve the effects of not easily falling off, improving the microstructure and mechanical properties, and reducing the risk of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

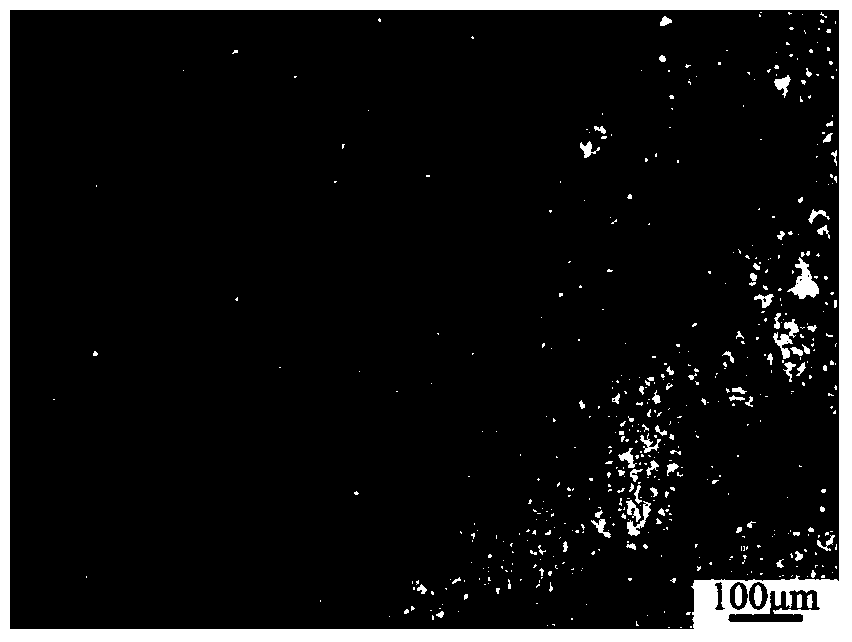

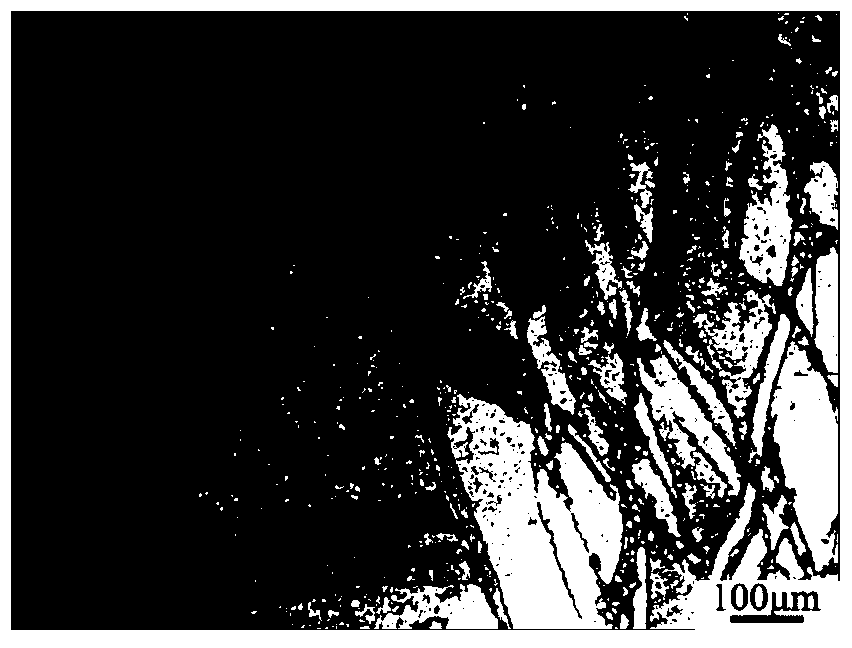

[0049] The regular Φ600mm×1260mm cylindrical rod blank was heated and kept, the initial grain size was 150μm, and the actual composition of the selected superalloy was measured as C: 0.06%; Al: 1.42%; Ti: 3.15%; Co: 13.5%; Cr: 20.0%; Mo: 4.1%; Ni balance.

[0050] Step 1. The initial cylindrical superalloy billet is heated and kept warm.

[0051] Put the high-temperature alloy billet bar in the effective area of the electric furnace, and pad it with refractory bricks below to ensure that the high-temperature alloy billet is heated evenly. The heating temperature of the electric furnace is controlled at 1060 ° C and kept for 15 hours.

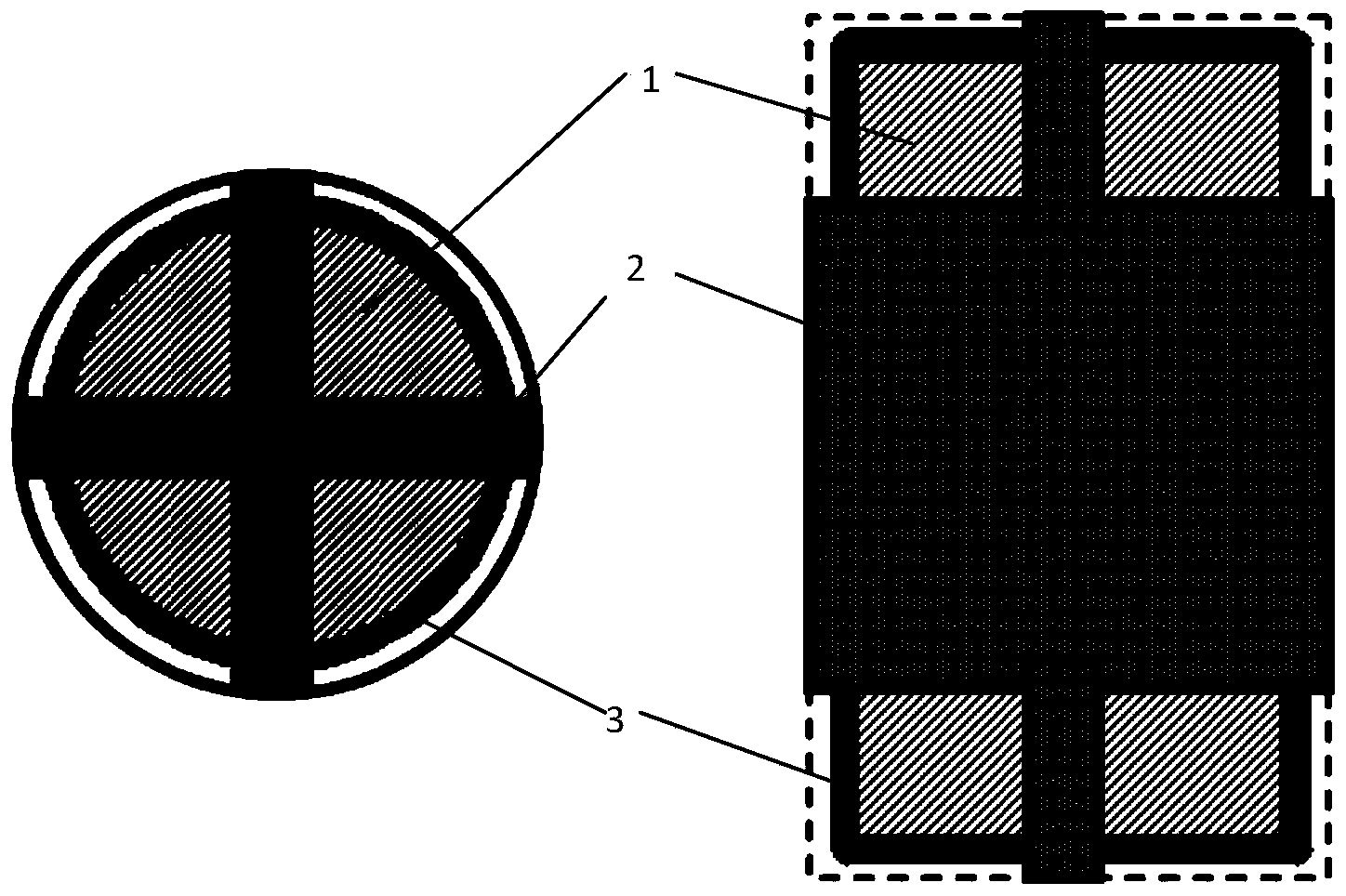

[0052] Step 2. After the billet is heated and kept warm, the billet is taken out for heat wrapping.

[0053] After heating the superalloy billet, take it out of the furnace and wrap it quickly. Firstly, soft wrap: wrap the superalloy billet with insulation cotton, and use a high-temperature adhesive to bond the superalloy billet and the insul...

Embodiment 2

[0061] In this example, a cylindrical rod blank of Φ508mm×1200mm was used for heating and heat preservation, and its initial grain size was 150 μm, and the actual composition of the selected superalloy was measured as C: 0.06%; Al: 1.45%; Ti: 3.10%; Co : 13.2%; Cr: 19.3%; Mo: 4.4%; Ni balance.

[0062] The difference between its sheath and forging process and embodiment 1 is:

[0063] The heating temperature of the electric furnace in step 1 is controlled at 1030°C, and the holding time is 10h;

[0064] The heating temperature of the electric furnace in step 3 is controlled at 1030° C., and the holding time is 3 hours;

[0065] Other steps are identical to Example 1. After testing, the room temperature, high temperature tensile properties and durability properties all meet the technical requirements.

Embodiment 3

[0067] In this example, a cylindrical rod blank of Φ600mm×1240mm was used for heating and heat preservation, and its initial grain size was 135 μm, and the actual composition of the selected superalloy was measured as C: 0.07%; Al: 1.38%; Ti: 3.5%; Co : 13.0%; Cr: 19.5%; Mo: 4.3%; Ni balance.

[0068] The difference between the sheathing and forging process and that of Example 1 is that the thickness of the soft sheathing in step 2 is 5mm, and the thickness of the stainless steel strip of the hard sheathing is 1.5mm.

[0069] Other steps are identical to Example 1. After testing, the room temperature, high temperature tensile properties and durability properties all meet the technical requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

| Height h | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com