Nutrient kudzuvine root slurry and preparation method thereof

A technology of kudzu root pulp and nutrition, which is applied in the field of kudzu root processing products and its preparation, and can solve the problems of no nutrition kudzu root pulp in patent literature and non-patent literature reports, poor brewability of kudzu root powder, loss of kudzu root nutrients, etc. , to achieve high raw material utilization rate, increase silky feeling, and prolong the effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Put the fresh kudzu root powder into a high-temperature frying pan, and fry at a temperature of 160°C for 20 minutes.

[0028] (2) Pass the fried pueraria powder, maltodextrin, yam powder, rice flour, xylitol, and sucralose through a 160-mesh sieve, weigh 60 parts of pueraria powder, 20 parts of maltodextrin, 10 parts of rice flour, and yam 5 parts of kudzu powder, 4.97 parts of xylitol and 0.03 part of sucralose are mixed evenly to make kudzu root nutrition powder.

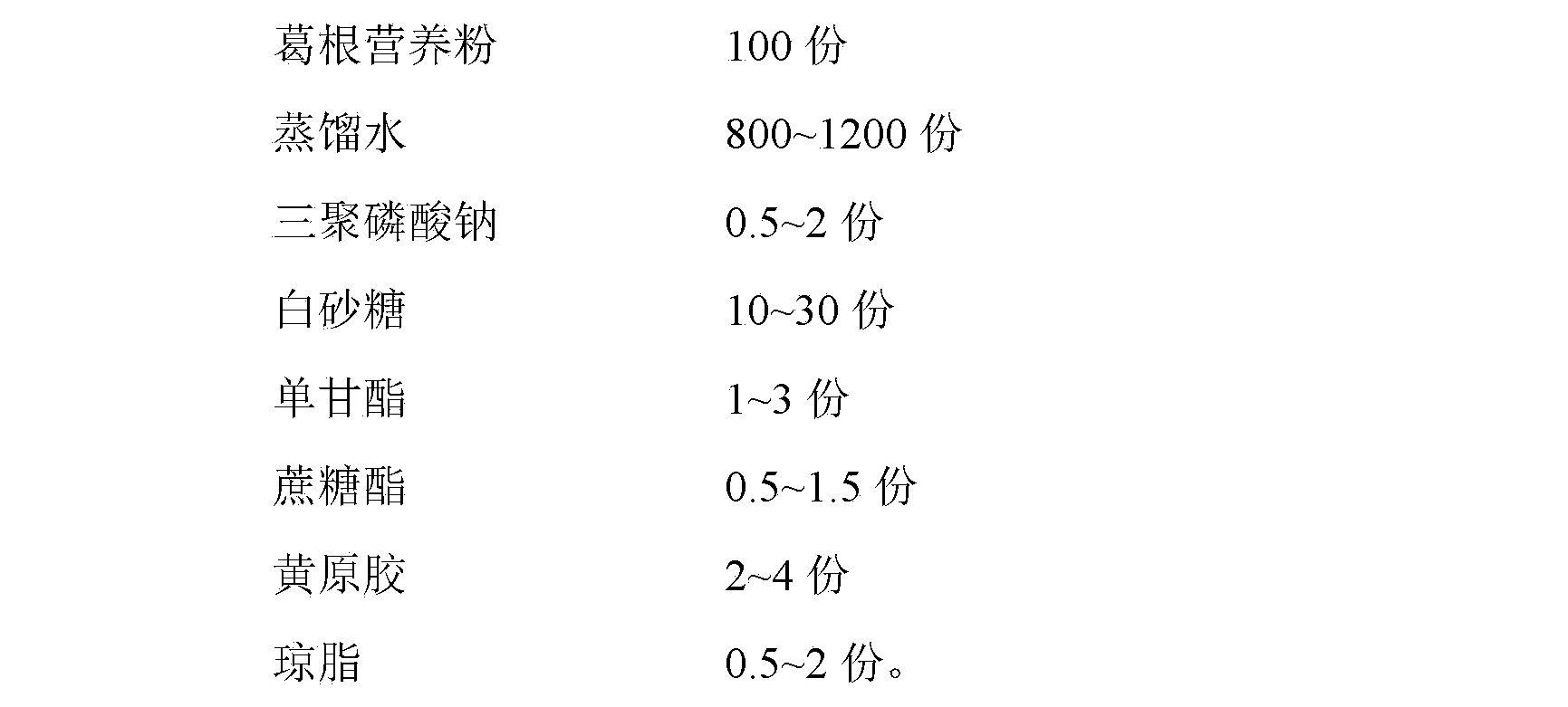

[0029] (3) Mix 100 parts of the above pueraria nutrient powder with 0.5 parts of sodium tripolyphosphate, 10 parts of white sugar, 1 part of monoglyceride, 0.5 part of sucrose ester, 2 parts of xanthan gum and 0.5 part of agar, and add 800 parts of distilled water , to be prepared into nutritious kudzu root pulp.

[0030] (4) Put the pueraria root pulp above on the electric furnace, and ripen it at 70°C for 8 minutes.

[0031] (5) Homogenize the kudzu root pulp that has been subjected to the above ag...

Embodiment 2

[0033] (1) Put the fresh kudzu root powder into a high-temperature frying pan, and fry at a temperature of 140°C for 30 minutes.

[0034] (2) Pass the fried pueraria powder, maltodextrin, yam powder, rice flour, xylitol, and sucralose through a 120-mesh sieve, weigh 40 parts of pueraria powder, 30 parts of maltodextrin, 20 parts of rice flour, and yam 7 parts of kudzu powder, 2.99 parts of xylitol and 0.01 part of sucralose are mixed evenly to make kudzu root nutrition powder.

[0035] (3) Mix 100 parts of the above pueraria nutrient powder with 2 parts of sodium tripolyphosphate, 30 parts of white sugar, 3 parts of monoglyceride, 1.5 parts of sucrose ester, 4 parts of xanthan gum and 2 parts of agar, and add 1200 parts of distilled water , to be prepared into nutritious kudzu root pulp.

[0036] (4) Put the pueraria root pulp above on an electric furnace, and ripen it at 85°C for 4 minutes.

[0037] (5) Homogenize the kudzu root pulp that has been aged above through a collo...

Embodiment 3

[0039] (1) Put the fresh kudzu powder into a high-temperature frying pan, and fry it at 150°C for 25 minutes.

[0040] (2) Pass the fried pueraria powder, maltodextrin, yam powder, rice flour, xylitol, and sucralose through a 140-mesh sieve, weigh 50 parts of pueraria powder, 25 parts of maltodextrin, 15 parts of rice flour, and yam 6 parts of kudzu powder, 3.98 parts of xylitol and 0.02 part of sucralose are mixed evenly to make kudzu root nutrition powder.

[0041] (3) Mix 100 parts of the above pueraria nutrient powder with 1 part of sodium tripolyphosphate, 15 parts of white sugar, 1.5 parts of monoglyceride, 0.75 part of sucrose ester, 2.5 parts of xanthan gum and 1 part of agar, and add 900 parts of distilled water , to be prepared into nutritious kudzu root pulp.

[0042] (4) Put the pueraria root pulp above on the electric furnace, and ripen it at 75°C for 6 minutes.

[0043] (5) Homogenize the kudzu root pulp that has been processed above through a colloid mill and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com