Preparation method of freeze-dried apple slices

A technology for apple slices and freeze-drying is applied in the field of food processing, which can solve the problems of loss of apple nutrients, poor slice shape, surface drying and shrinkage of apple slices, etc., and achieves the effect of reducing cost and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Technological process: select apples that are free from disease and rot—cleaning—sterilization—removing cores—cutting—plating—freeze-drying—packaging.

[0020] Process steps:

[0021] 1. Choose apples that are free from disease and rot, and after cleaning, sterilization, peel off the skin, stems and cores mechanically or manually.

[0022] 2. Cut into slices or fan shapes.

[0023] 3. Spreading tray: spread the apple slices evenly in the material tray, and then transfer to the shelf of the material cart.

[0024] 4. Push the material trolley into the freeze-drying bin, start the condensing system one hour before feeding to make it operate normally, the temperature of the refrigerant in the material circulation reaches below -30°C, turn on the vacuum pump unit, and the vacuum degree must reach 133.3 within 30 minutes Below Pa, the material is frozen at this time.

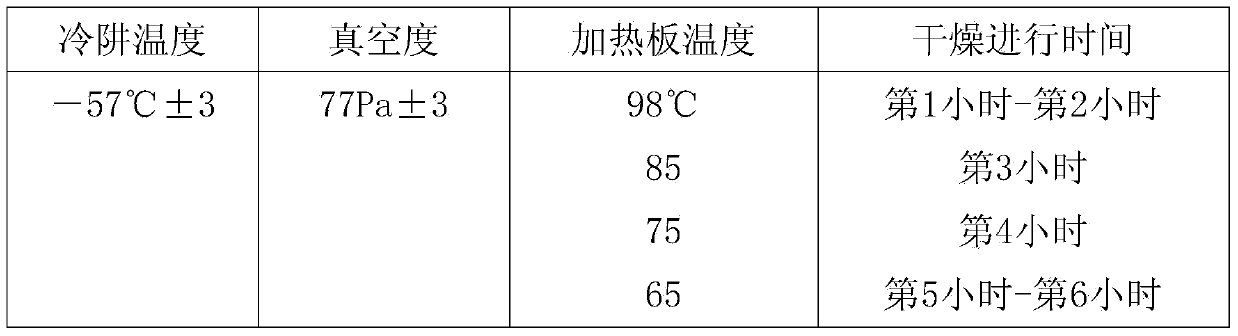

[0025] 5. Turn on the heating system and heat according to the set temperature (as shown in Table 1). Wh...

Embodiment 2

[0030] Technological process: select apples that are free from disease and rot—cleaning—sterilization—removing cores—cutting—plating—freeze-drying—packaging.

[0031] Process steps:

[0032] 1. Choose apples that are free from disease and rot, and after cleaning, sterilization, peel off the skin, stems and cores mechanically or manually.

[0033] 2. Cut into slices or fan shapes.

[0034] 3. Color protection: Soak the sliced apple slices in 10% sugar water for 20 minutes.

[0035] 4. Laying the tray: Take out the apple slices and spread the apple slices evenly in the material tray.

[0036] 5. Push the material trolley into the freeze-drying bin, start the condensing system 1 hour before feeding to make it work normally, the temperature of the refrigerant in the material circulation reaches below -30°C, turn on the vacuum pump unit, and the vacuum degree must reach 133.3 within 30 minutes Below Pa, the material is frozen at this time.

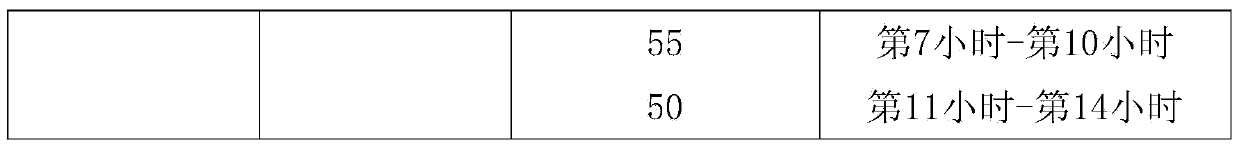

[0037] 6. Turn on the heating syst...

Embodiment 3

[0041] Technological process: select apples that are disease-free and non-rotten—cleaning—sterilization—core removal—slicing—drying—laying—freeze drying—packaging.

[0042] Process steps:

[0043] 1. Choose apples that are free from disease and rot, and after cleaning, sterilization, peel off the skin, stems and cores mechanically or manually.

[0044] 2. Cut into slices or fan shapes.

[0045] 3. To protect the color, soak the sliced apple slices in 10% sugar water for 20 minutes.

[0046] 4. Take out the apple slices, put the apple slices into a draining mesh bag, and turn on the water spinner for 1 minute.

[0047] 5. Spreading tray: Spread the apple slices evenly in the material tray after the water is shaken.

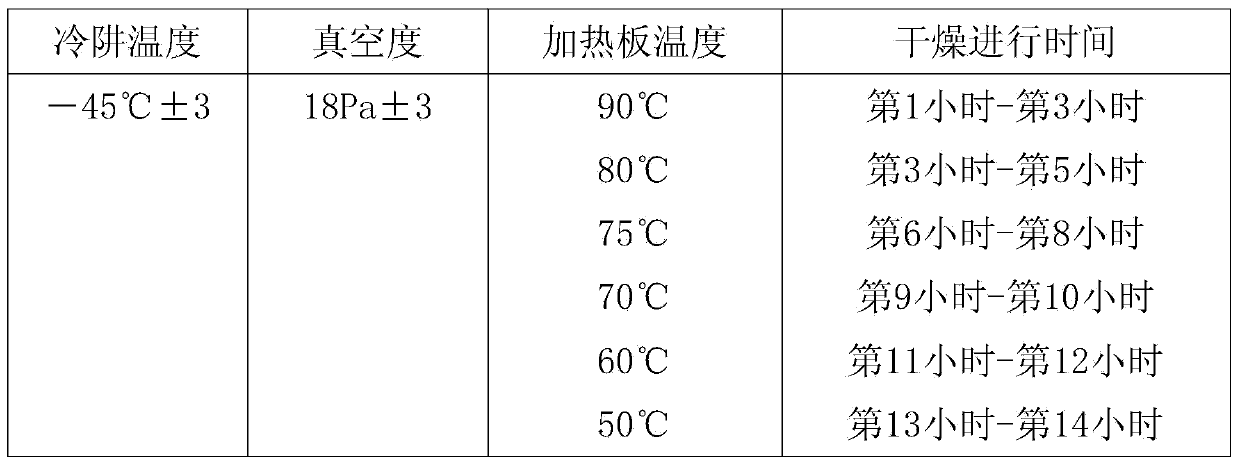

[0048] 6. Push the material cart into the freeze-drying bin, start the condensing system 1 hour before feeding to make it operate normally, the temperature of the refrigerant in the material circulation reaches below -30°C, turn on the vacuum pump unit, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com