Method for bonding metal member and resin member

A technology for metal components and resin components, applied in metal processing equipment, connection, welding equipment, etc., to achieve the effect of preventing the reduction of joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

[0107]

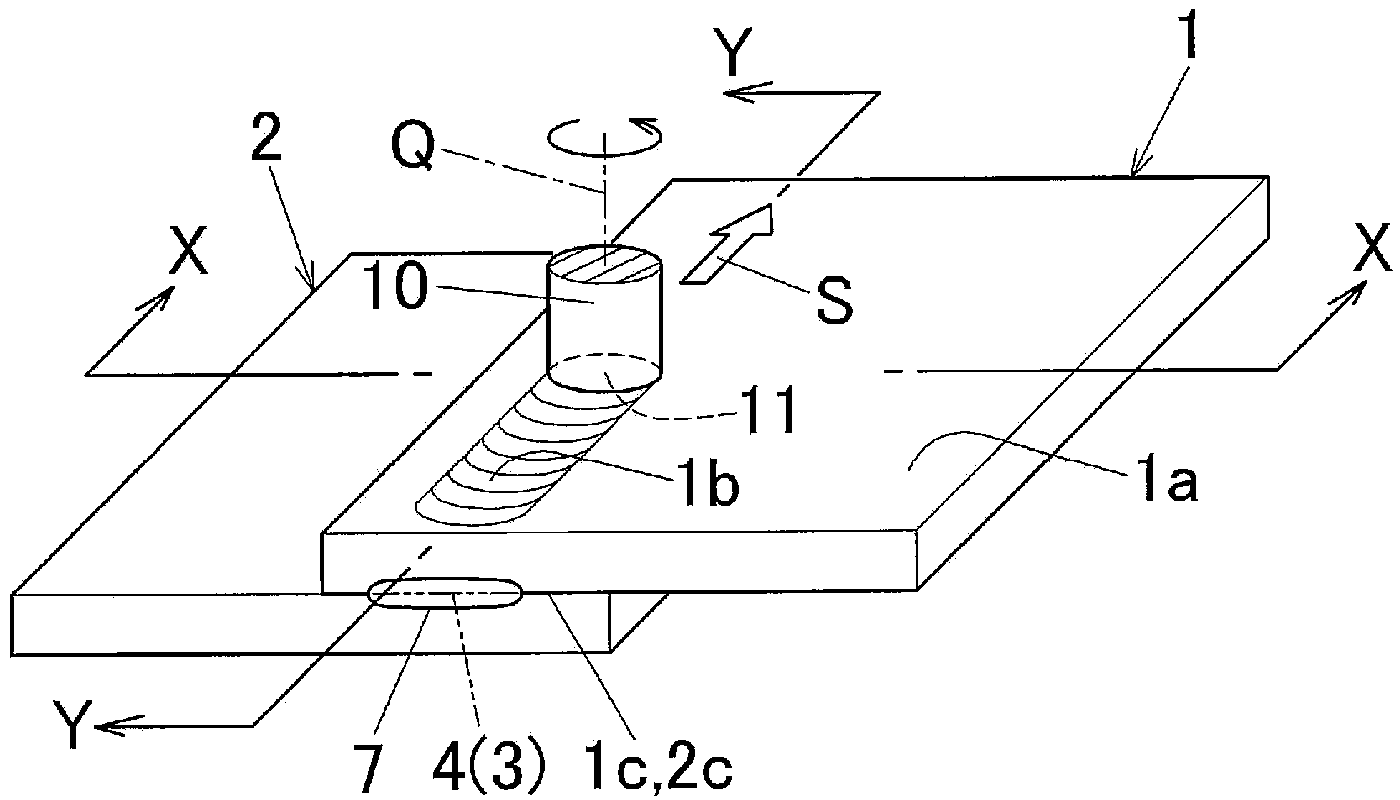

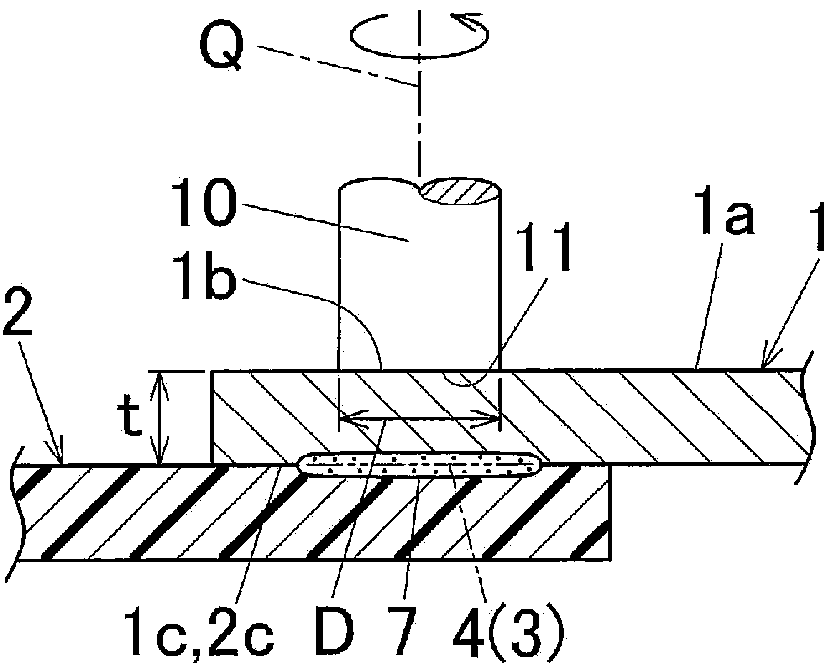

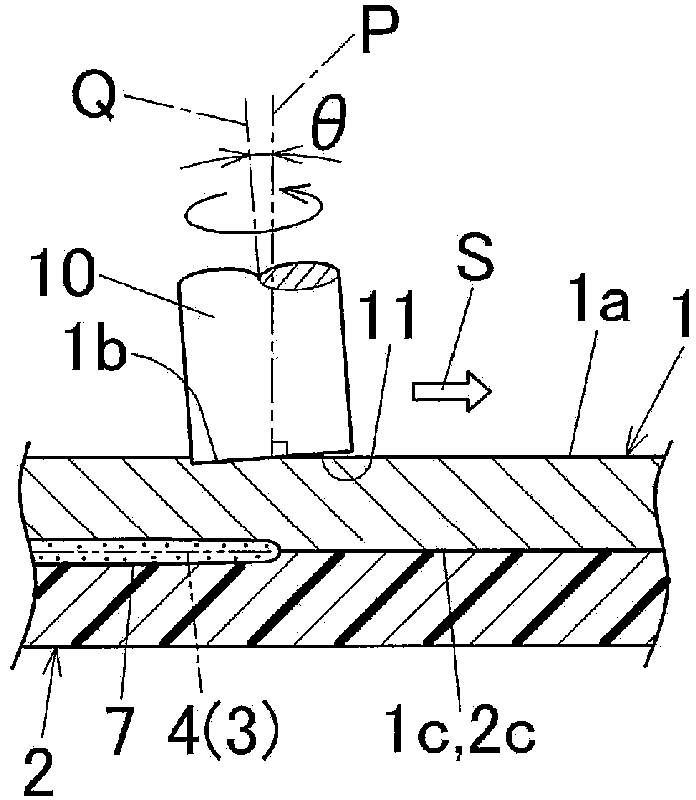

[0108] The flat metal member 1 made of various materials and the flat resin member 2 made of various materials were prepared. The materials of the prepared metal member 1 and resin member 2 are shown in the columns of "material of metal member" and "material of resin member" in Table 1, respectively.

[0109] In the "Material of Metal Member" column in Table 1, the symbols described after the term "aluminum alloy" are aluminum alloy symbols. In addition, "A2017" of the aluminum alloy symbol is a wrought alloy, while "AC4C" is a cast material. In addition, the term "anodized" means that the entire surface of the aluminum alloy metal member has been anodized by a known method. The symbol "AZ31" written after the term "magnesium alloy" is the symbol for magnesium alloy. The melting point of aluminum alloy A2017 is 640°C, and the melting point of AC4C is 610°C. The melting point of the magnesium alloy AZ31 is 632°C. The dimensions of the metal members 1 are all 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com