Solid electrolyte membrane and lithium ion battery

A technology of solid-state electrolyte membrane and solid-state electrolyte, applied in secondary batteries, circuits, electrical components, etc., can solve problems affecting lithium ion conductivity, poor crystallinity, lithium ion diffusion blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Li 2 S, P 2 S 5 with GeS 2 According to the molar ratio of 5:1:1, it is placed in a high-energy ball milling device to be ball-milled until uniform, and the powder after ball-milling is obtained;

[0057] Then the ball-milled powder was placed in a quartz tube filled with argon, and treated at 600 °C for 8 h to obtain Li 10 GeP 2 S 12 Crystalline particles, followed by slow cooling to room temperature;

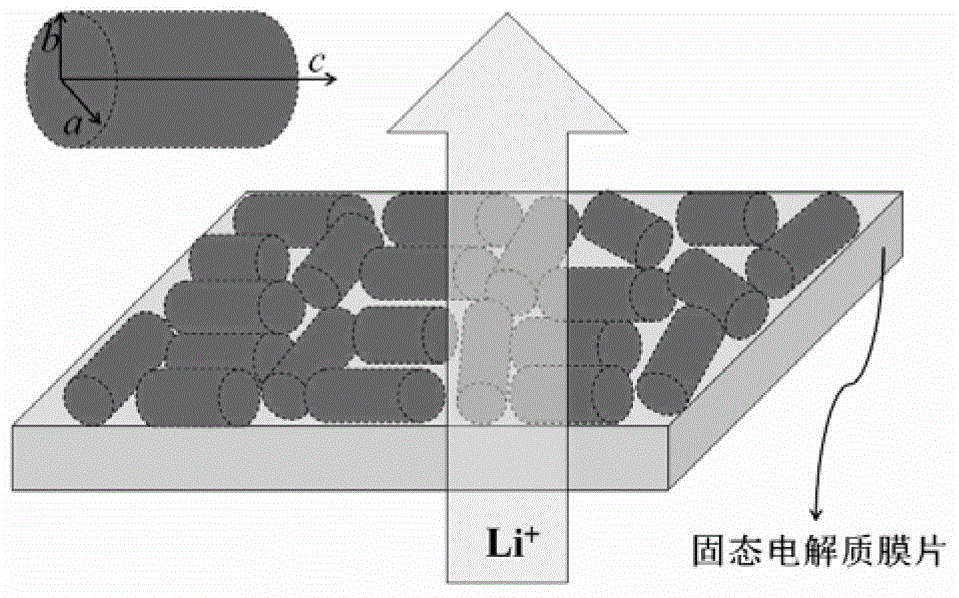

[0058] will get Li 10 GeP 2 S 12 The crystal particles and the binder silicone grease are kept at 200°C for 5 hours, and then placed on a vibrating table at a temperature of 200°C in a rectangular quartz tube (the bottom is sealed and the top is open, and the thickness of the rectangle is 0.05mm). , the vibrating table drives the quartz tube to vibrate 30,000 times at a frequency of 300 times / min, and compacts it into a diaphragm. After the completion, the quartz tube is broken and the diaphragm is taken out (thickness is 0.05mm); the measured Li 10 GeP 2 S ...

Embodiment 2

[0060] Li 2 S, P 2 S 5 with GeS 2 According to the molar ratio of 5:1:1, it is placed in a high-energy ball milling device to be ball-milled until uniform, and the powder after ball-milling is obtained;

[0061] Then the ball-milled powder was placed in a quartz tube filled with argon, and treated at 600 °C for 8 h to obtain Li 10 GeP 2 S 12 Crystalline particles, followed by slow cooling to room temperature;

[0062] will get Li 10 GeP 2 S 12 The crystal particles and the binder silicone grease are kept at 200°C for 4 hours, and then placed on a vibrating table at a temperature of 200°C in a rectangular quartz tube (the bottom is sealed and the top is open, and the thickness of the rectangle is 0.05mm). , the vibrating table drives the quartz tube to vibrate 30,000 times at a frequency of 300 times / min, and compacts it into a diaphragm. After the completion, the quartz tube is broken and the diaphragm is taken out (thickness is 0.05mm); the measured Li 10 GeP 2 S 12...

Embodiment 3

[0064] Li 2 S, P 2 S 5 with GeS 2 According to the molar ratio of 5:1:1, it is placed in a high-energy ball milling device to be ball-milled until uniform, and the powder after ball-milling is obtained;

[0065] Then the ball-milled powder was placed in a quartz tube filled with argon, and treated at 600 °C for 8 h to obtain Li 10 GeP 2 S 12 Crystalline particles, followed by slow cooling to room temperature;

[0066] will get Li 10 GeP 2 S 12 The crystal particles and the binder silicone grease are kept at 200°C for 2 hours, and then placed on a vibrating table at a temperature of 200°C in a rectangular quartz tube (the bottom is sealed and the top is open, and the thickness of the rectangle is 0.05mm). , the vibrating table drives the quartz tube to vibrate 30,000 times at a frequency of 300 times / min, and compacts it into a diaphragm. After the completion, the quartz tube is broken and the diaphragm is taken out (thickness is 0.05mm); the measured Li 10 GeP 2 S ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com