Method for testing bolt joint surface contact damping characteristics

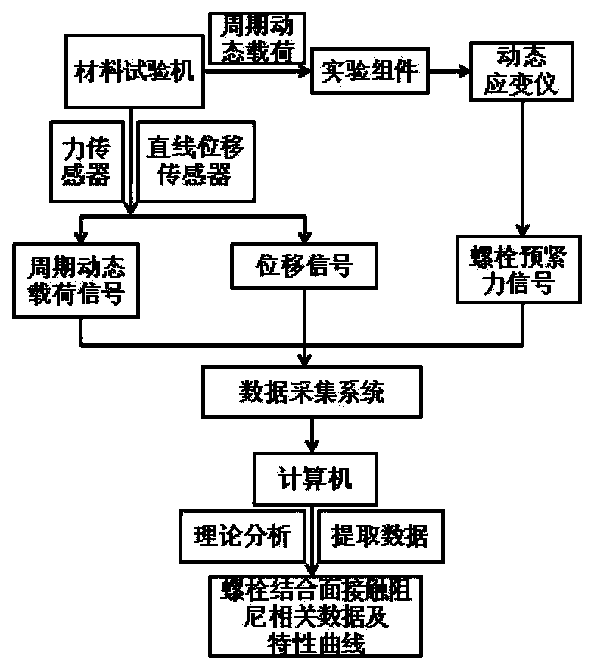

A bolt joint surface, contact damping technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problems of measurement and identification of the difficulty of separating the joint surface damping, and achieve the analysis method is simple and feasible, The effect of easy separation and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

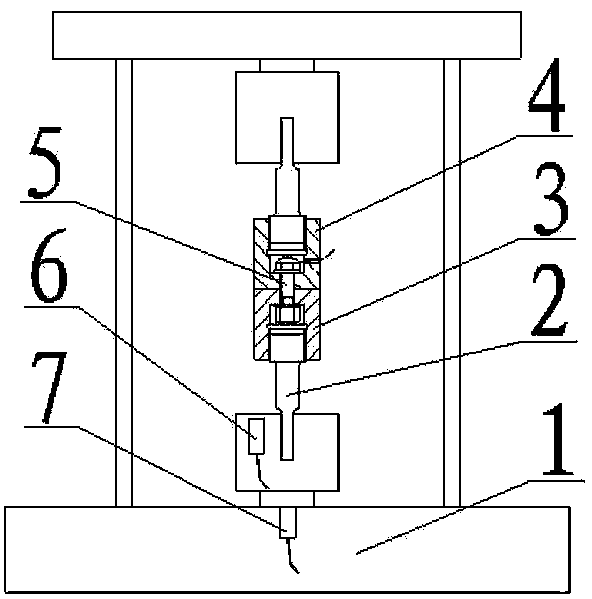

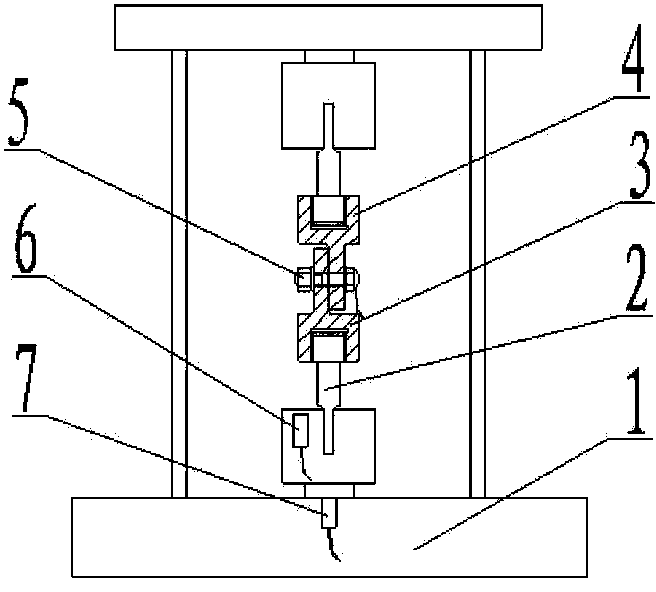

[0039] The device and method for testing the contact damping characteristics of the bolt joint surface of the present invention will be further described in detail below in conjunction with the working principle and the structural drawings.

[0040] Such as figure 2 with image 3 , the two screw rods 2 are threadedly connected with the upper test piece 4 and the lower test piece 3 respectively, and the active end surface of the upper test piece 4 and the active end surface of the lower test piece 3 fit together to form a joint surface. The high-strength bolts 5 pass through the through holes of the upper and lower test pieces 4 and 3 and are perpendicular to the joint surface, and exert force on the high-strength bolts 5 to form a pre-tightening force on the joint surface. In this way, the experimental assembly of the contact damping characteristics of the bolt joint surface is formed. The bolt joint surface formed by the mutual fitting of the upper specimen 4 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com