Carpet cleaning agent and preparation method thereof

A cleaning agent and carpet technology, applied in the field of cleaning agents, can solve the problems of no sterilization function, inability to effectively remove carpet dust, stains, dirt, etc., and achieve the effects of good sterilization effect, prevention of secondary pollution, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

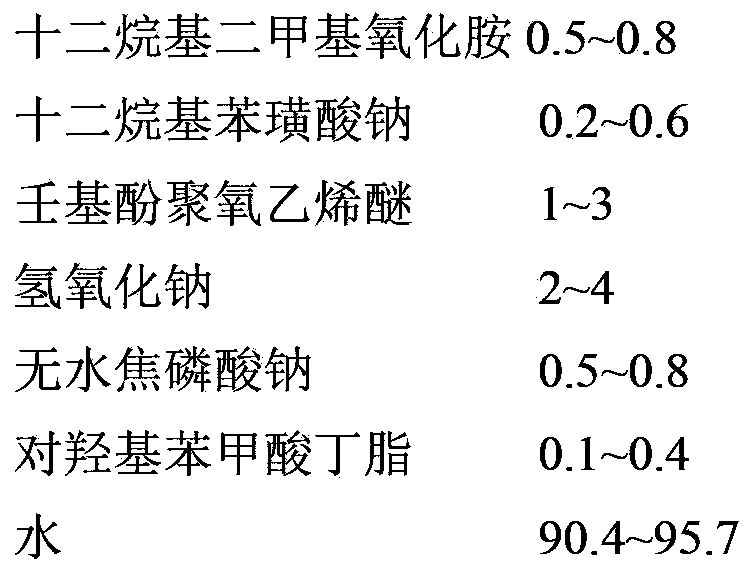

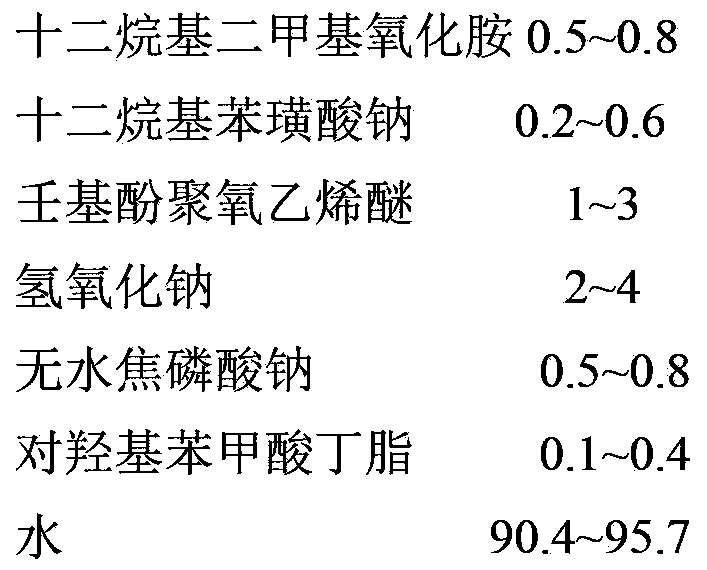

[0018] A kind of carpet cleaning agent, composition is as follows:

[0019] 95.7kg water, 0.5kg dodecyl dimethyl amine oxide, 0.2kg sodium dodecylbenzenesulfonate, 1kg nonylphenol polyoxyethylene ether, 2kg sodium hydroxide, 0.5kg anhydrous sodium pyrophosphate, 0.1 kg Butyl p-hydroxybenzoate.

[0020] The preparation method of above-mentioned carpet cleaning agent, step is as follows:

[0021] (1) Put 77.7kg of water, 0.5kg of dodecyl dimethyl amine oxide, 0.2kg of sodium dodecylbenzene sulfonate, and 1kg of nonylphenol polyoxyethylene ether into the reaction kettle in sequence, and fully stir until completely dissolved to obtain mixture, set aside.

[0022] (2) Put 18kg of water, 2kg of sodium hydroxide, 0.5kg of anhydrous sodium pyrophosphate, and 0.1kg of butyl p-hydroxybenzoate into another reaction kettle in sequence, and stir until completely dissolved to obtain a mixture.

[0023] (3) When the mixture in step (2) is cooled to room temperature, add the mixture in ste...

Embodiment 2

[0025] A kind of carpet cleaning agent, composition is as follows:

[0026] 452kg water, 4kg dodecyl dimethyl amine oxide, 3kg sodium dodecylbenzenesulfonate, 15kg nonylphenol polyoxyethylene ether, 20kg sodium hydroxide, 4kg anhydrous sodium pyrophosphate, 2kg p-hydroxybenzoic acid butyl fat.

[0027] The preparation method of above-mentioned carpet cleaning agent, step is as follows:

[0028] ⑴Put 372kg of water, 4kg of dodecyl dimethyl amine oxide, 3kg of sodium dodecylbenzene sulfonate, and 15kg of nonylphenol polyoxyethylene ether into the reaction kettle in sequence, stir well until completely dissolved, and obtain a mixture for later use .

[0029] (2) Put 80kg of water, 20kg of sodium hydroxide, 4kg of anhydrous sodium pyrophosphate, and 2kg of butyl p-hydroxybenzoate into another reaction kettle in sequence, and stir until completely dissolved to obtain a mixture.

[0030] (3) When the mixture in step (2) is cooled to room temperature, add the mixture in step (1) a...

Embodiment 3

[0032] A kind of carpet cleaning agent, composition is as follows:

[0033] 930kg water, 7kg dodecyl dimethyl amine oxide, 4kg sodium dodecylbenzenesulfonate, 20kg nonylphenol polyoxyethylene ether, 30kg sodium hydroxide, 6kg anhydrous sodium pyrophosphate, 3kg p-hydroxybenzoic acid butyl fat.

[0034] The preparation method of above-mentioned carpet cleaning agent, step is as follows:

[0035] (1) Put 753kg of water, 7kg of dodecyl dimethyl amine oxide, 4kg of sodium dodecylbenzene sulfonate, and 20kg of nonylphenol polyoxyethylene ether into the reaction kettle in turn, stir fully until completely dissolved, and obtain a mixture for later use .

[0036] (2) Put 177kg of water, 30kg of sodium hydroxide, 6kg of anhydrous sodium pyrophosphate, and 3kg of butyl p-hydroxybenzoate into another reaction kettle in sequence, and stir until completely dissolved to obtain a mixture.

[0037] (3) When the mixture in step (2) is cooled to room temperature, add the mixture in step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com