Environment-friendly salt for ice and snow melting and preparation method thereof

A kind of salinity, environment-friendly technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problem of high price, achieve the effect of low cost, low corrosion, and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

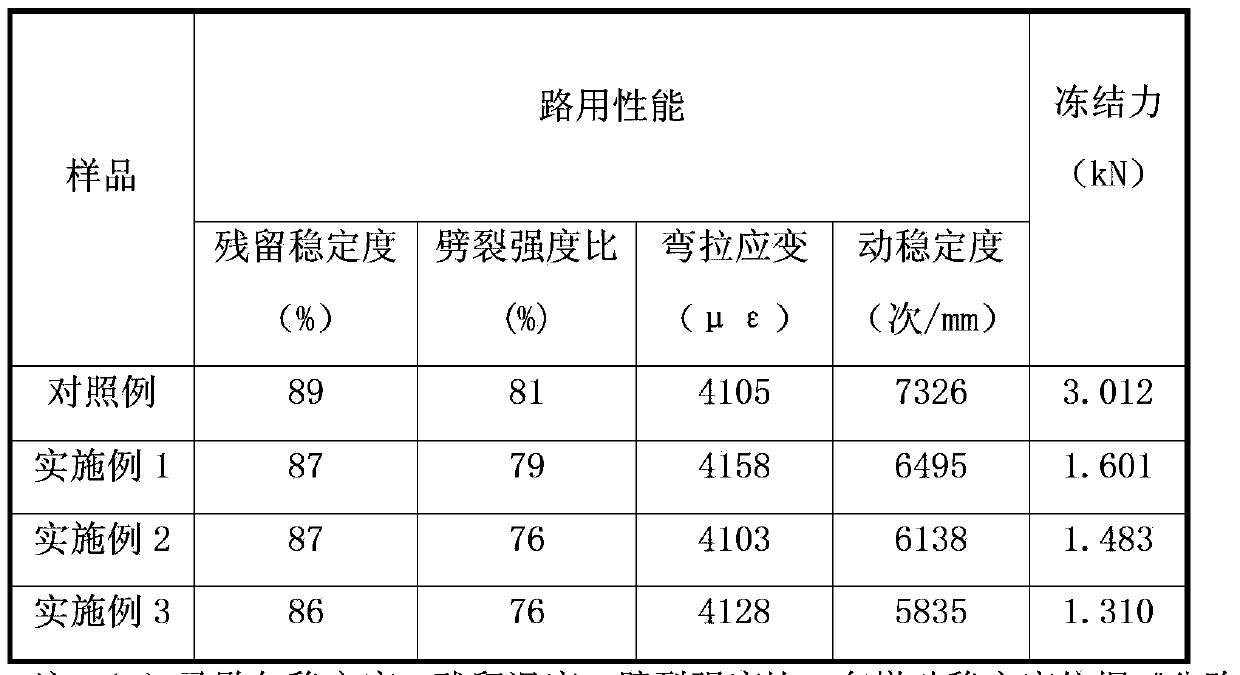

Embodiment 1

[0038] A method for preparing environment-friendly snow melting salt, the method comprises the following steps:

[0039] Step 1, take the following components according to weight percentage:

[0040] Magnesium acetate 10g, calcium acetate 30g, calcium oxide 5g, basalt 30g, aluminate coupling agent 15g, silica gel 10g;

[0041] Step 2, put the weighed magnesium acetate, calcium acetate, calcium oxide and silica gel into a stirring pot, and stir evenly at room temperature (25°C) for 5 minutes;

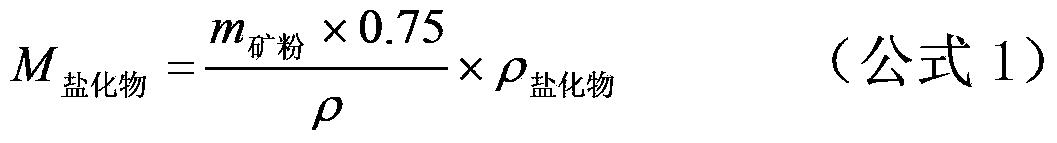

[0042] Step 3: put the product stirred in Step 2 into a mineral powder briquetting machine and grind it for 10 minutes, then mix it evenly with a modifier, put it in an oven after mixing, and keep it at a constant temperature for 3 hours at 120°C to obtain a mixture;

[0043]Step 4, put the basalt into the mineral powder briquetting machine and grind for 15 minutes, then add the ground porous mineral material and the mixture obtained in Step 3 to the ball mill and grind for 15 minutes t...

Embodiment 2

[0046] The preparation method of this embodiment is as follows:

[0047] Step 1, take the following components according to weight percentage:

[0048] Magnesium acetate 15g, calcium acetate 45g, calcium oxide 2g, basalt 23g, aluminate coupling agent 5g, silica gel 10g.

[0049] Step 2, put the weighed magnesium acetate, calcium acetate, calcium oxide and silica gel into a stirring pot, and stir evenly at room temperature (25°C) for 10 minutes;

[0050] Step 3: put the product stirred in Step 2 into a mineral powder briquetting machine and grind it for 20 minutes, then mix it evenly with a modifier, put it in an oven after mixing, and keep it at a constant temperature for 3 hours at 140°C to obtain a mixture;

[0051] Step 4, put the basalt into the mineral powder briquetting machine and grind for 20 minutes, then add the ground porous mineral material and the mixture obtained in Step 3 to the ball mill and grind for 20 minutes to obtain powder granular salt;

[0052] Step 5...

Embodiment 3

[0054] The preparation method of this example is the same as that of Example 1, except that the components weighed in Step 1 are: 13.3g of magnesium acetate, 31.7g of calcium acetate, 5g of calcium oxide, 10g of basalt, and aluminate coupling agent 20g, silica gel 20g.

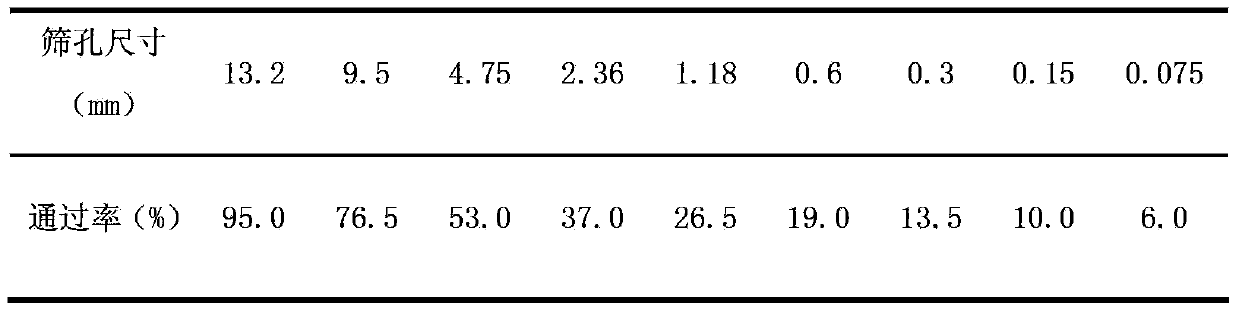

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com