Continuously-running moving bed chemical-looping reaction system

A moving bed reactor and reaction system technology, which is applied in the fields of clean energy utilization and energy saving and emission reduction, can solve problems such as difficulty in oxygen carrier transportation, and achieve the effect of increasing the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

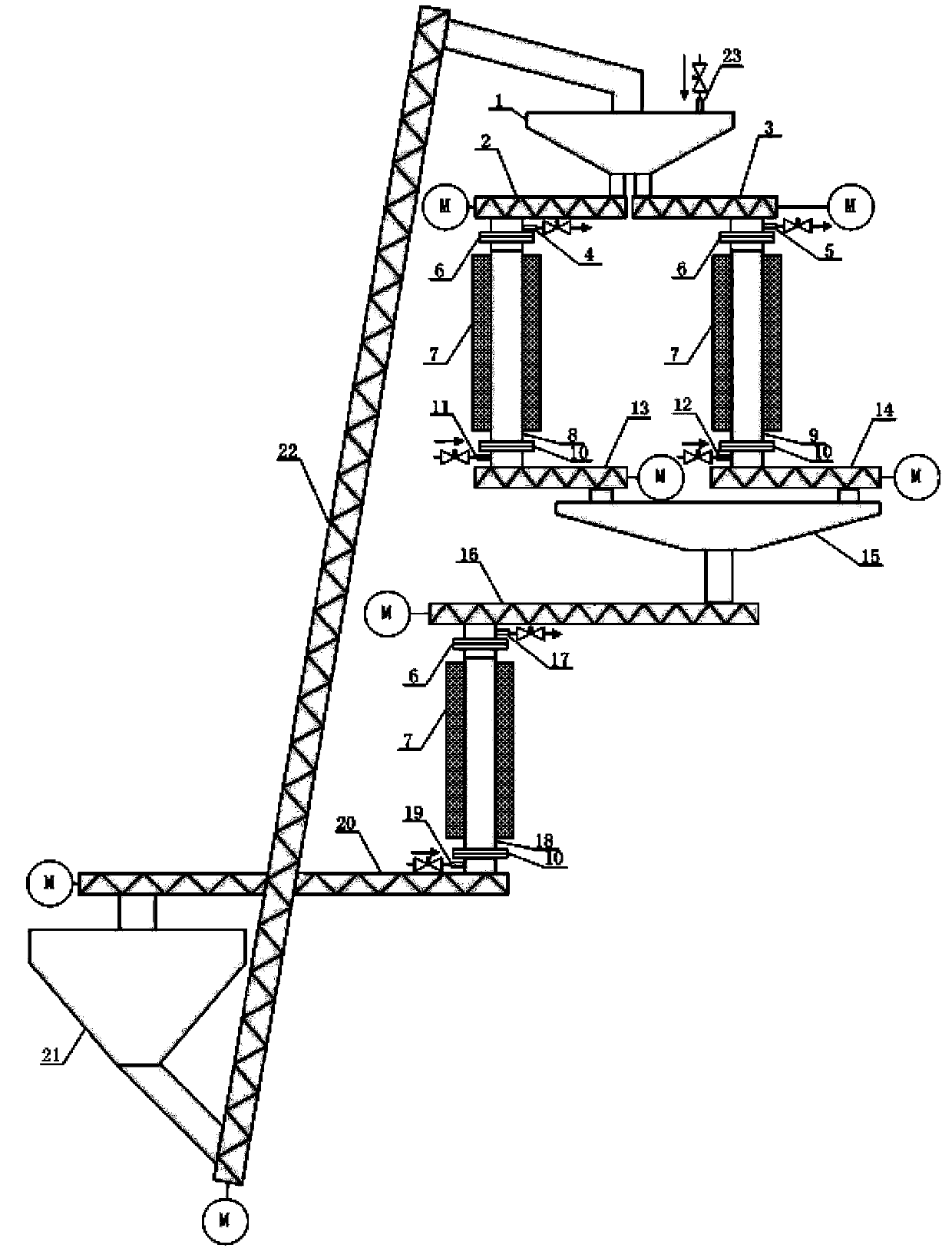

[0025] The moving bed chemical chain reaction system and its working process according to the present invention will be described below with reference to the accompanying drawings.

[0026] image 3 It is a schematic structural diagram of a continuously operating moving bed chemical chain reaction system according to an embodiment of the present invention.

[0027] Such as image 3 As shown, the continuously operating moving bed chemical chain reaction system includes an upper storage tank (1), a middle storage tank (15), a lower storage tank (21), and three moving bed reactors—hydrogen production reactor ( 8), the air reactor (9), the fuel reactor (18), and the screw driving mechanism, each moving bed reactor is respectively provided with the moving bed reactor inlet pipe (11, 12, 19) and the moving bed reactor row Trachea (4, 5, 17).

[0028]The screw drive mechanism includes a screw feeder (2, 3, 16) located at the top of each moving bed reactor, a screw discharger (13, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com