Thermochromism coating with variable emissivity and preparation method thereof

A thermochromic and emissivity technology, applied in chemical instruments and methods, layered products, metal layered products, etc., to achieve the effects of overcoming low yield, easy large-scale production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

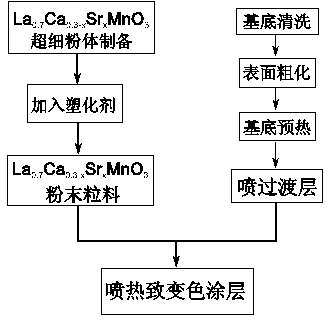

Method used

Image

Examples

Embodiment 1

[0027] Step 1, the commercially available nickel-based alloy is cleaned by ultrasonic vibration with absolute ethanol, dried, and the surface is roughened with corundum particles of 80-120 microns, and then put into the plasma spraying sample stage, and after being preheated by the plasma flame, Spray a NiCrAl transition layer with a thickness of 90 microns.

[0028] Step 2, weigh 31.5397 grams of La respectively according to the stoichiometric ratio 2 o 3 , 5.5368 g CaCO 3 , 4.083 g SrCO 3 , and 24.0469 g MnO 2 Raw material powder, prepared La 0.7 Ca 0.2 Sr 0.1 MnO 3 The bulk material is ground into an ultrafine powder with an average particle size of 10 microns by using a high-energy ball mill.

[0029] Step 3: Add 3 grams of polyvinyl alcohol into a beaker filled with 97 grams of deionized water, place it in a constant temperature water bath at 80°C, stir thoroughly until the polyvinyl alcohol is completely dissolved, and obtain a plasticized polyvinyl alcohol with ...

Embodiment 2

[0033] Step 1. Clean the commercially available stainless steel substrate with anhydrous ethanol ultrasonic vibration and then dry it. Use corundum particles of 80-120 microns to roughen the surface, and then put it into the plasma spraying sample stage. A transition layer of NiCrAl with a thickness of 100 microns.

[0034] Step 2, weigh 31.2997 grams of La respectively according to the stoichiometric ratio 2 o 3 , 4.5331 g CaCO 3 , 5.4702 g SrCO 3 , and 23.8639 g MnO 2 Raw material powder, prepared La 0.7 Ca 0.165 Sr 0.135 MnO 3 The bulk material is ground into an ultrafine powder with an average particle size of 9.7 microns by using a high-energy ball mill.

[0035] Step 3: Add 8 grams of polyvinyl alcohol into a beaker filled with 92 grams of deionized water, place it in a constant temperature water bath at 80°C, stir thoroughly until the polyvinyl alcohol is completely dissolved, and obtain a plasticized polyvinyl alcohol with a concentration of 8% after cooling. ...

Embodiment 3

[0043] Step 1: Clean the commercially available zirconia substrate with anhydrous ethanol ultrasonic vibration, dry it, put it into the plasma spraying sample stand, and spray a layer of NiCrAlY transition layer with a thickness of 90 microns after preheating by the plasma flame.

[0044] Step 2, weigh 31.2997 grams of La respectively according to the stoichiometric ratio 2 o 3 , 4.5331 g CaCO 3 , 5.4702 g SrCO 3 , and 23.8639 g MnO 2 Raw material powder, prepared La 0.7 Ca 0.165 Sr 0.135 MnO 3 The bulk material is ground into an ultrafine powder with an average particle size of 9.7 microns by using a high-energy ball mill.

[0045] Step 3: Add 5 grams of polyvinyl alcohol into a beaker containing 95 grams of deionized water, place it in a constant temperature water bath at 80°C, stir well until the polyvinyl alcohol is completely dissolved, and obtain a plasticized polyvinyl alcohol with a concentration of 5% after cooling. agent for later use.

[0046] Step 4: Add 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com