Touch panel glass splitter

A touch panel and dismantling machine technology, applied in the mechanical field, can solve problems such as missing products, poor effects, and affecting use, and achieve the effect of saving materials, simple structure, and overall exquisiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

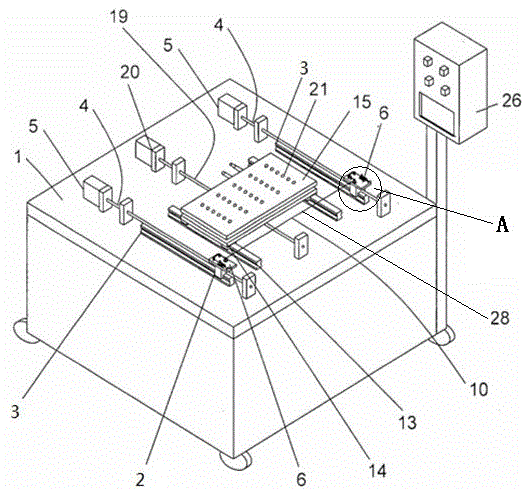

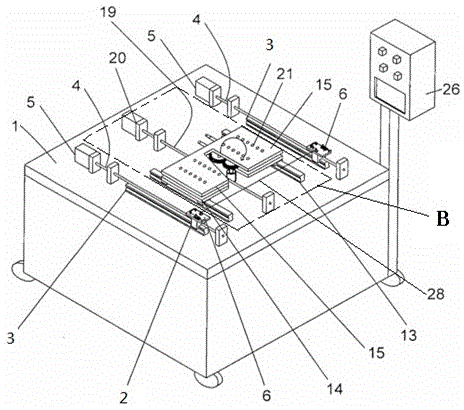

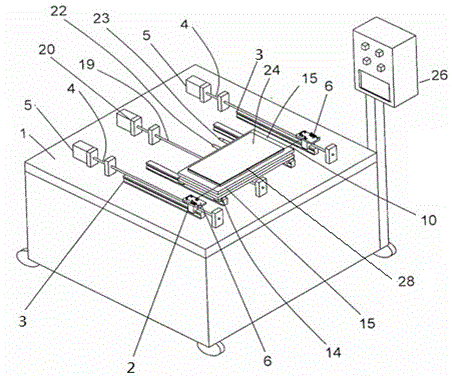

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 4 Shown is a touch panel glass splitting machine, including a bed platform 1, a first pair of slide rails 3 are arranged in parallel on the bed platform 1, and a slide table 2 is respectively arranged on the first pair of slide rails 3. The sliding table 2 is provided with a cutting line device for cutting and separating the touch panel 24; the sliding table 2 can move on the first pair of slide rails 3 respectively through the cooperative drive of the lead screw group 4 and the rear motor 5;

[0027] Such as figure 2 and Figure 6 As shown, a second pair of slide rails 13 is arranged in the middle of the first pair of slide rails 3, and a stage 14 is arranged on the second pair of slide rails 13, and a vacuum stage 15 for carrying and fixing a touch panel 24 is arranged on the stage 14. A fourth motor 18, a driving gear 17 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com