Charging basket for thermal treatment of synchronizer gear hub

A synchronizer and material technology, which is applied in heat treatment furnaces, heat treatment equipment, lighting and heating equipment, etc., can solve problems such as serious deformation, and achieve uniform carburized layer, reduced deformation, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

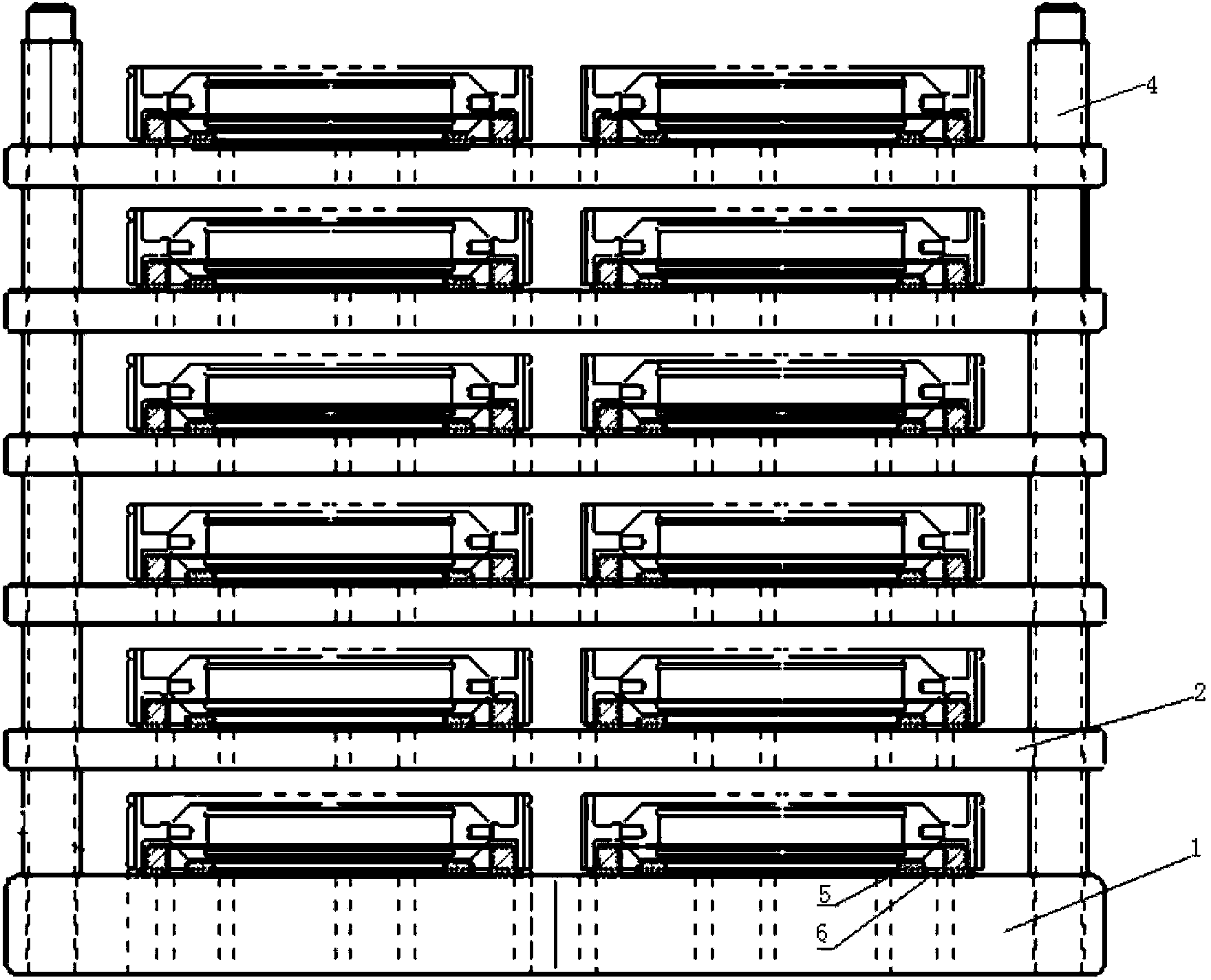

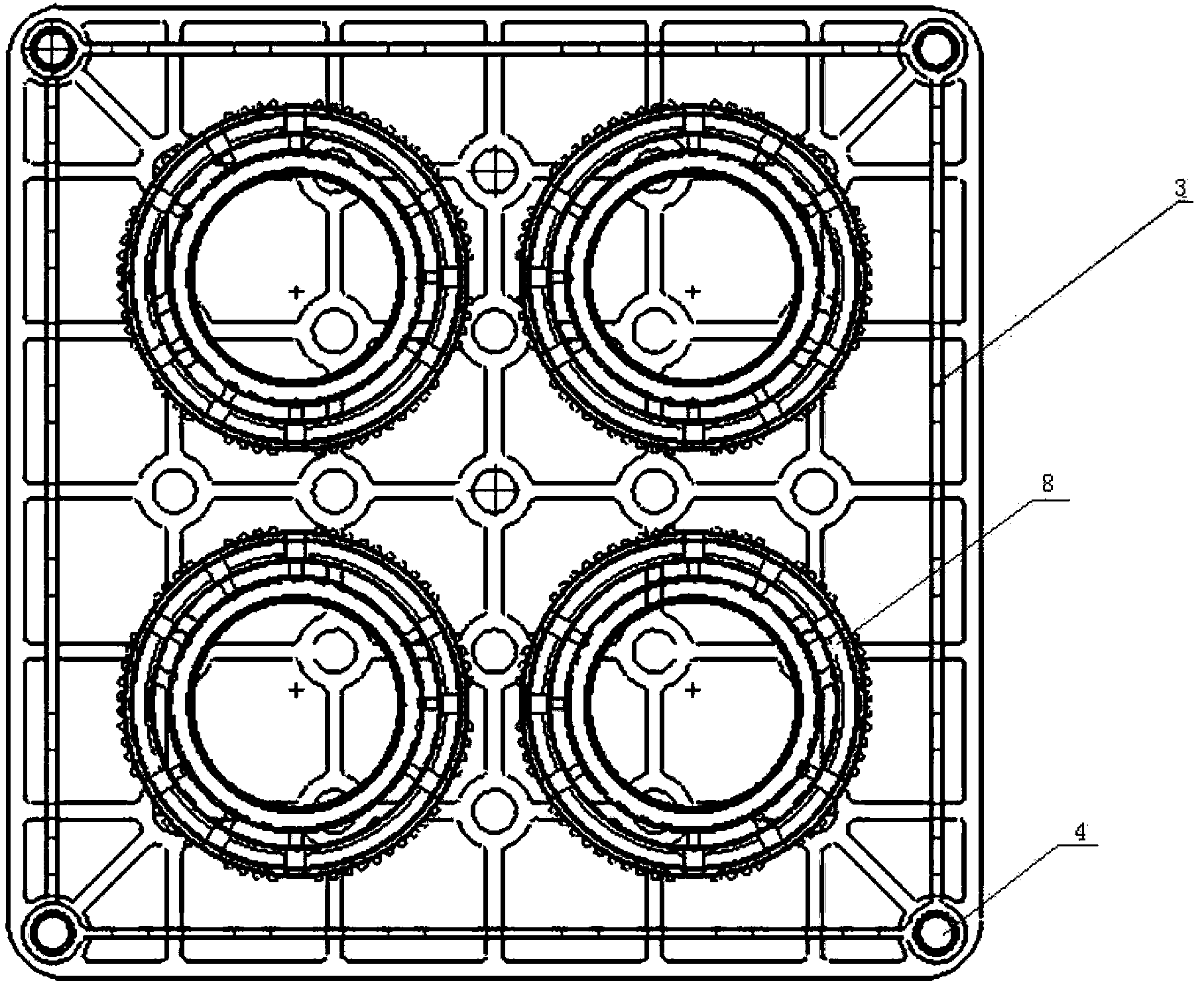

[0021] Such as figure 2 , 3 As shown, the present invention provides a material basket for heat treatment of the synchronizer gear hub 8, which includes a main bottom plate 1 of the material basket and five flat plates 2, and the main bottom plate 1 of the material basket and each flat plate 2 are arranged at intervals from bottom to top, They are connected by four basket columns 4, and four workpiece gasket groups are respectively arranged on the main bottom plate 1 of the basket and each flat disk 2. On the main base plate 1 of the material basket and each flat plate 2, a material basket coaming plate 3 is arranged between every two adjacent material basket columns 4, and forms a rectangle.

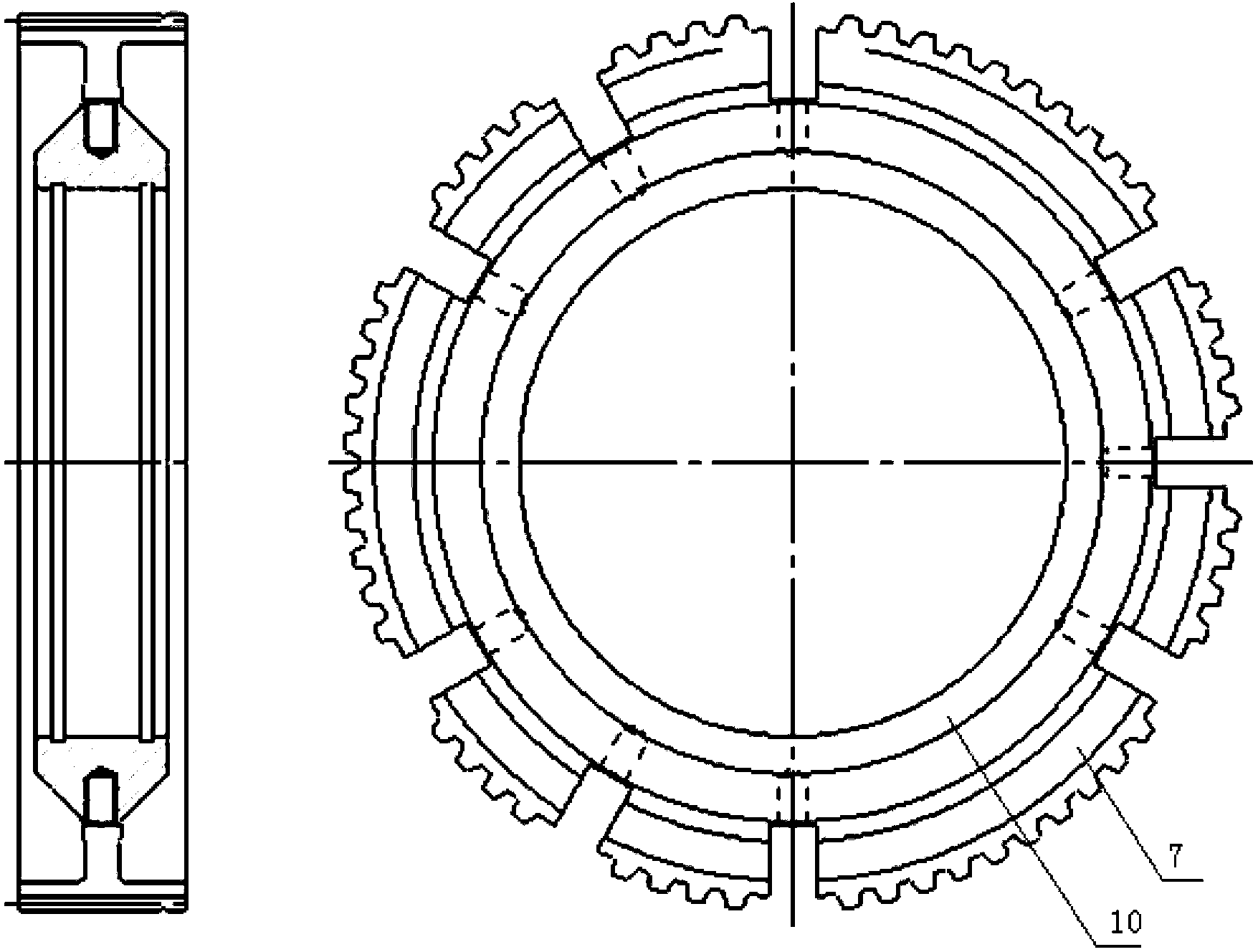

[0022] The workpiece gasket set includes a workpiece load-bearing inner washer 5 and a workpiece outer washer 6 sleeved on the outside of the workpiece load-bearing inner washer 5. There is a distance between the workpiece load-bearing inner washer 5 and the workpiece outer washer 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com