Recovery method for isobutene in cracking process of methyl tert-butyl ether

A technology of methyl tert-butyl ether and isobutene, which is applied in the field of separation and recovery of isobutene, can solve the problems of no industrial use value and resource waste of light components at the top of the light removal tower, so as to improve resource utilization, avoid waste, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

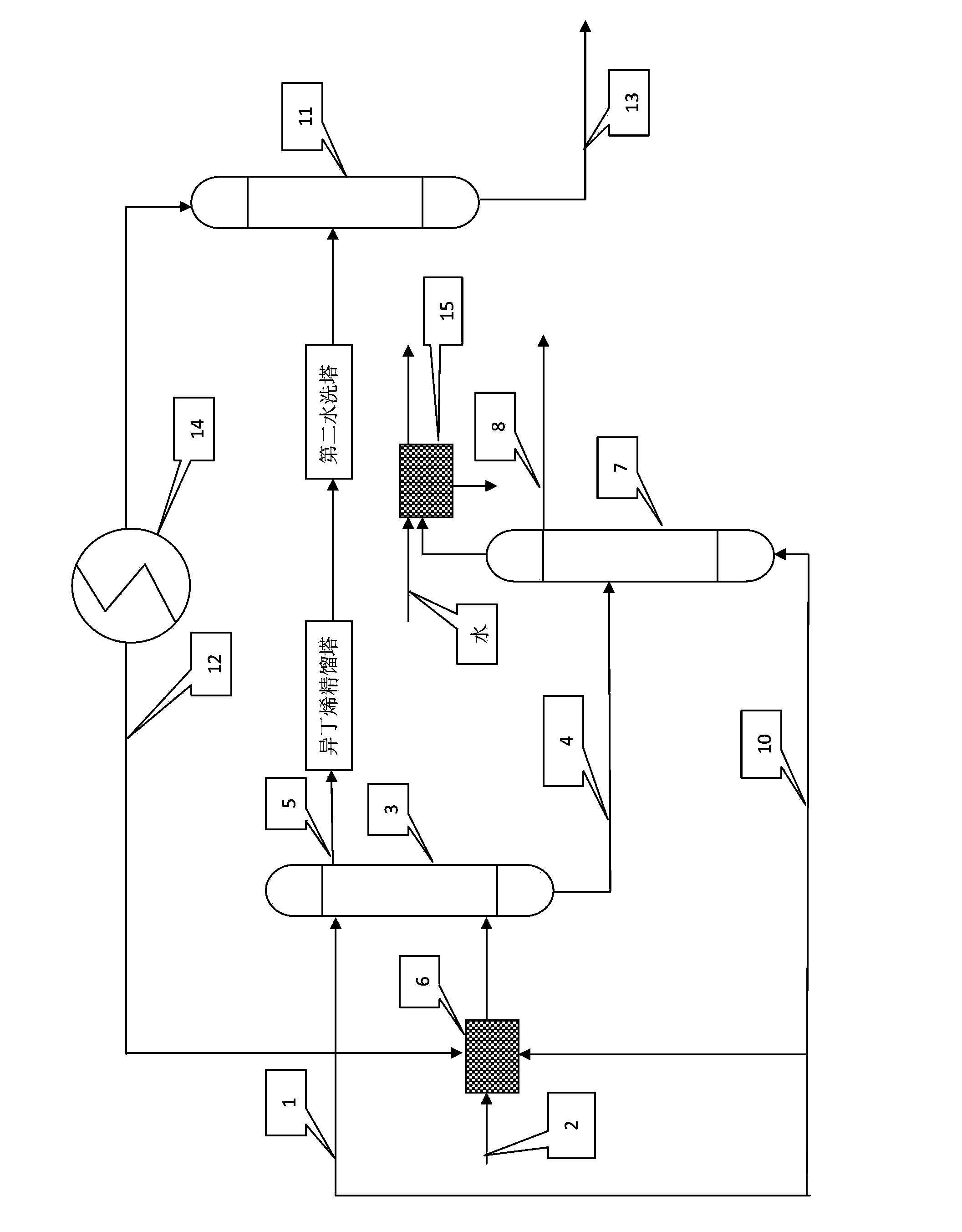

Method used

Image

Examples

Embodiment 1

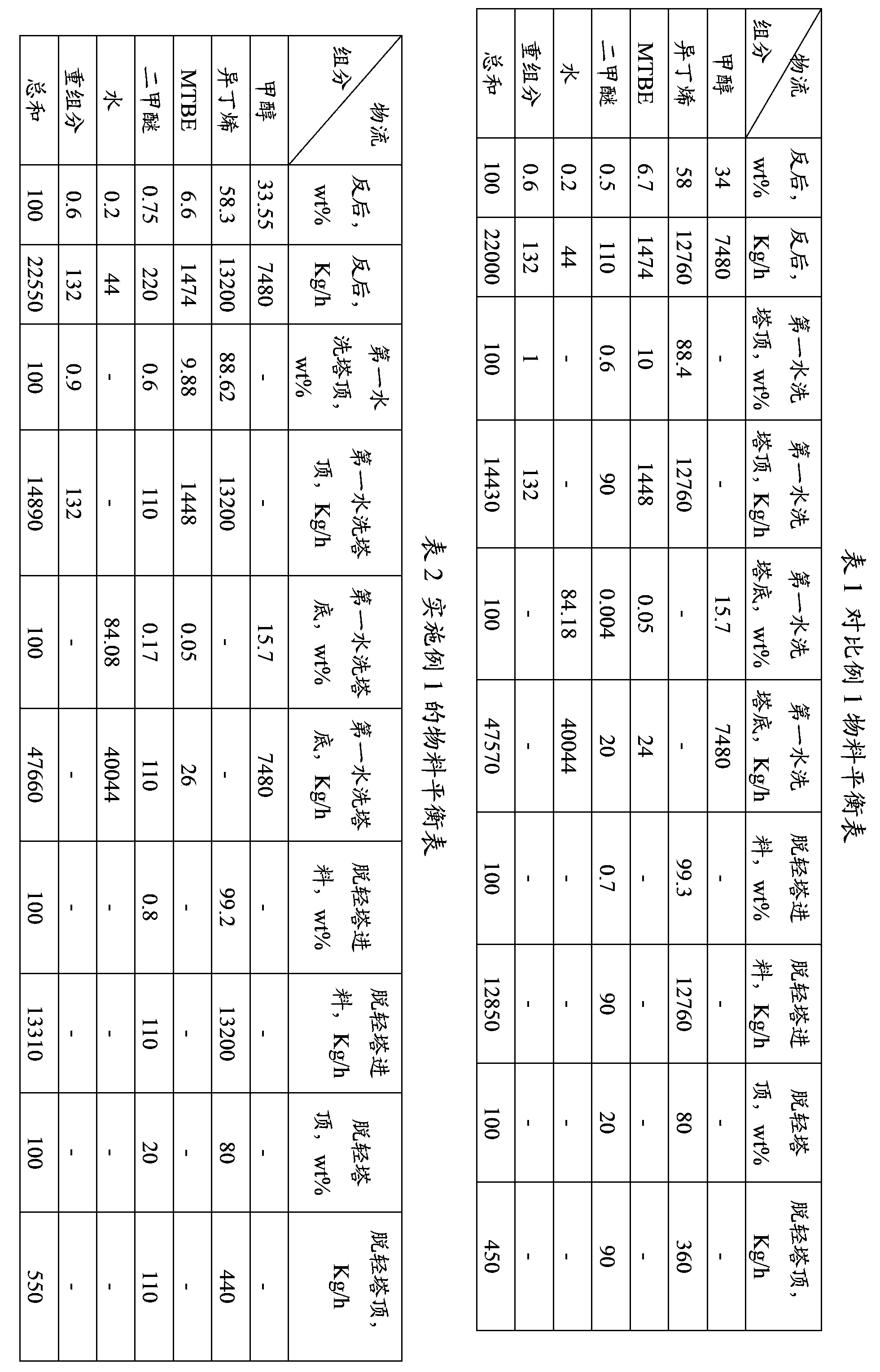

[0027] With comparative example 1, the difference is that a static mixer is arranged at the bottom of the first water washing tower, and the stream comprising dimethyl ether and isobutylene at the top of the light removal tower after decompression is mixed with the back material and water in a static state. Mix well in the container, and then pass into the first water washing tower. See Table 2 and Table 3 for the data.

Embodiment 2

[0031] The same as Comparative Example 2, the difference is that a static mixer is arranged at the bottom of the first water washing tower, and the stream comprising dimethyl ether and isobutylene at the top of the light removal tower after decompression is statically mixed with the back material and water Mix well in the container, and then pass into the first water washing tower. See Table 5 and Table 3 for the data.

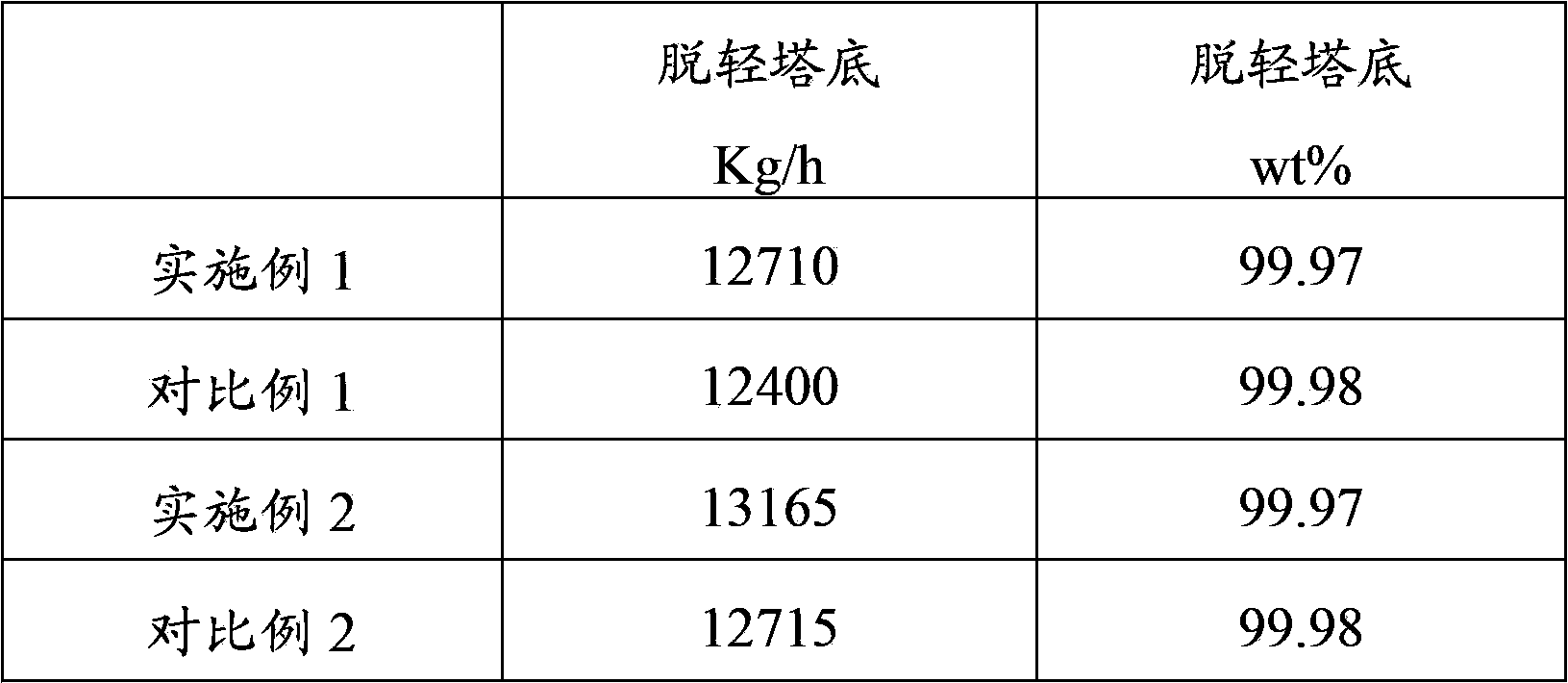

[0032] table 3

[0033]

[0034] It can be known from the data in the table that the separation and recovery of isobutene according to the method provided by the present invention increases the output of isobutene and improves the economic benefit under the premise of ensuring that the isobutene with a purity greater than 99.9% is obtained at the bottom of the light removal tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com