Thin-film transistor and producing method thereof

A technology of thin-film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, and electrical components. The effect of stability and good interface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

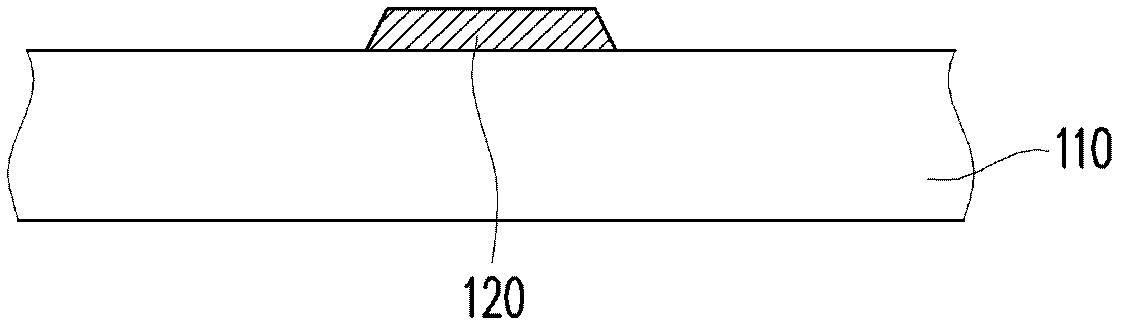

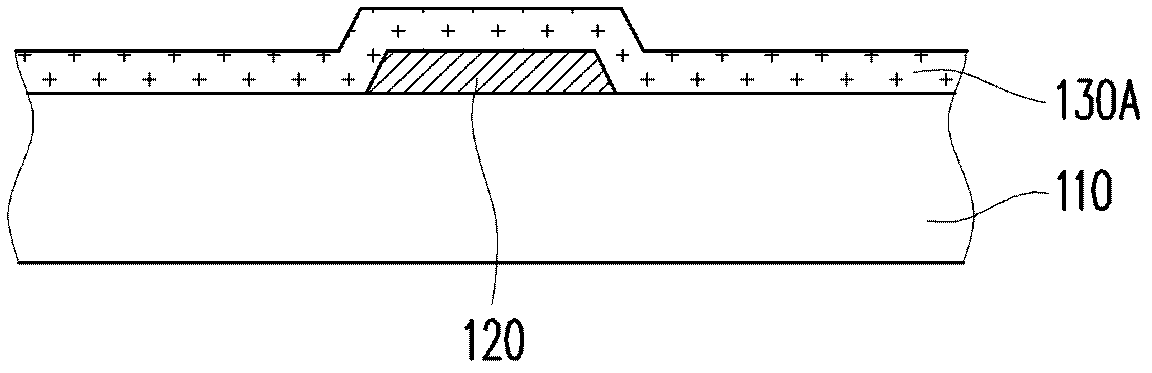

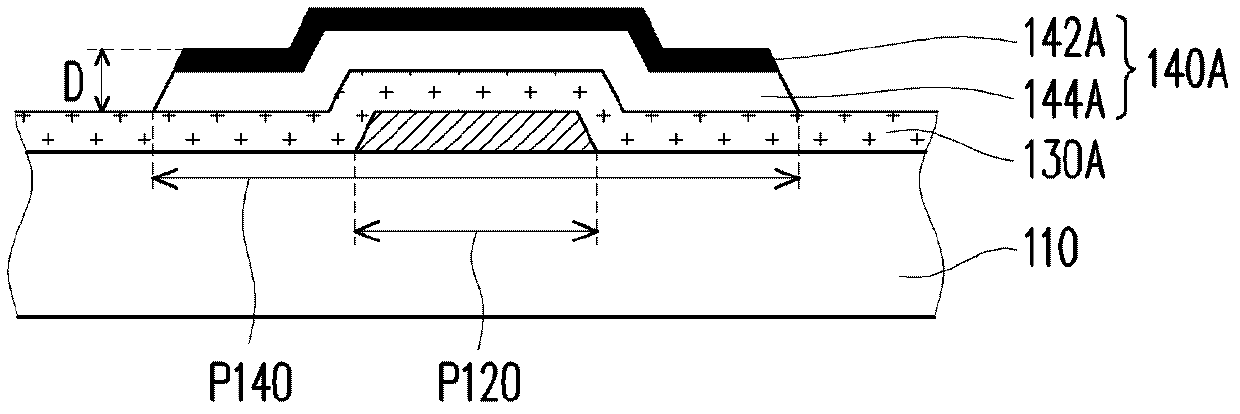

[0048] Figure 1A to Figure 1F It is a schematic cross-sectional view of the manufacturing process of a thin film transistor according to an embodiment of the present invention.

[0049] Please refer to Figure 1A , firstly, a substrate 110 is provided, and a gate 120 is formed on the substrate 110, wherein the gate 120 can be made of a metal stack or a single metal layer, and its material is, for example, aluminum or copper with good conductivity and other metals. Of course, according to actual needs, the grid 120 can be made of non-metal conductive material.

[0050] Please refer to Figure 1B , forming a gate insulating layer 130A on the substrate 110 , and making the gate insulating layer 130A cover the gate 120 . The material of the gate insulating layer 130A is, for example, an inorganic material (such as silicon oxide, silicon nitride, silicon oxynitride, silicon aluminum oxide, or a stacked layer of at least two of the above materials), an organic material, or a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com