Whole aeration cyclone vertical shaft

A shaft, the whole process technology, applied in the field of aeration and corrosion reduction, to achieve the effect of high operation safety, ingenious conception and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

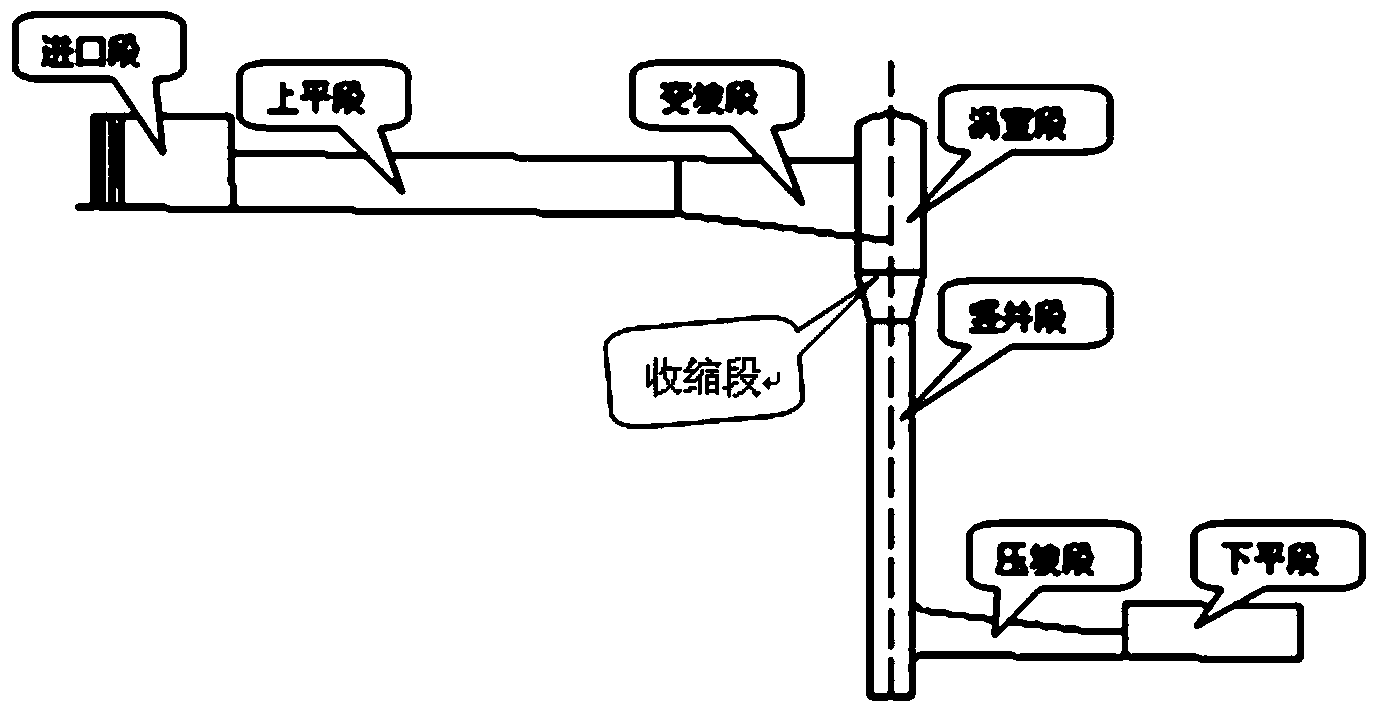

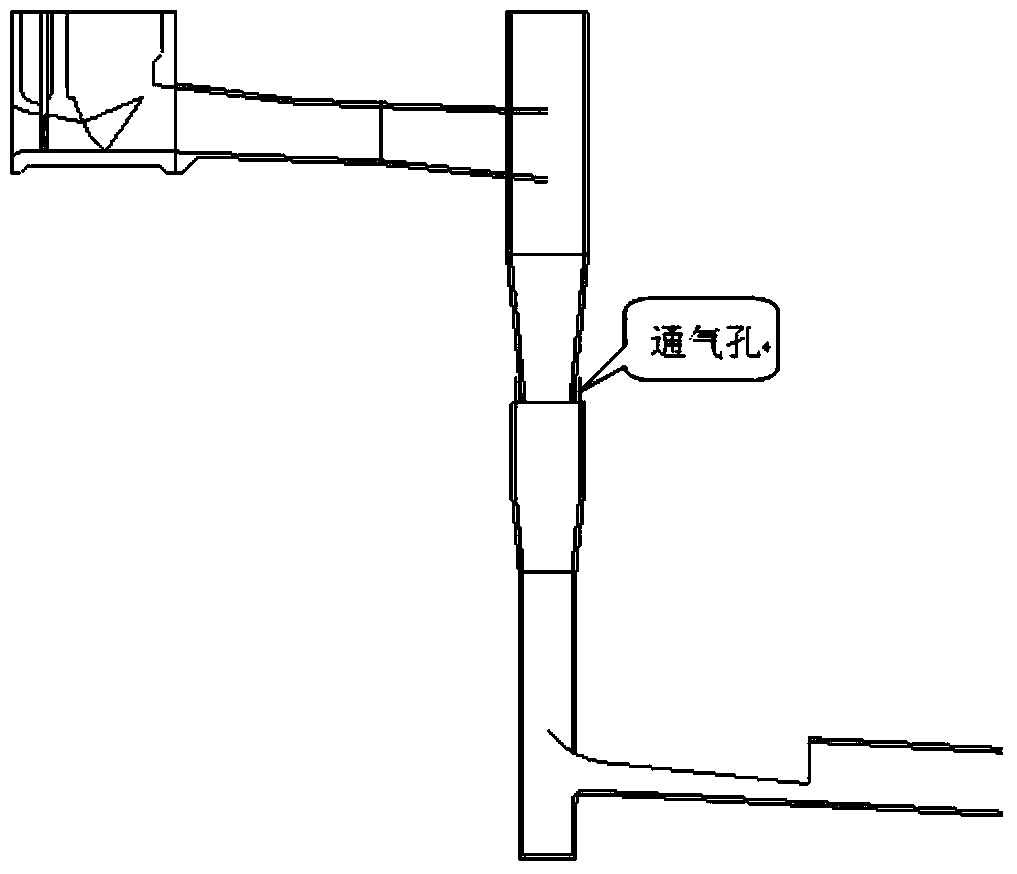

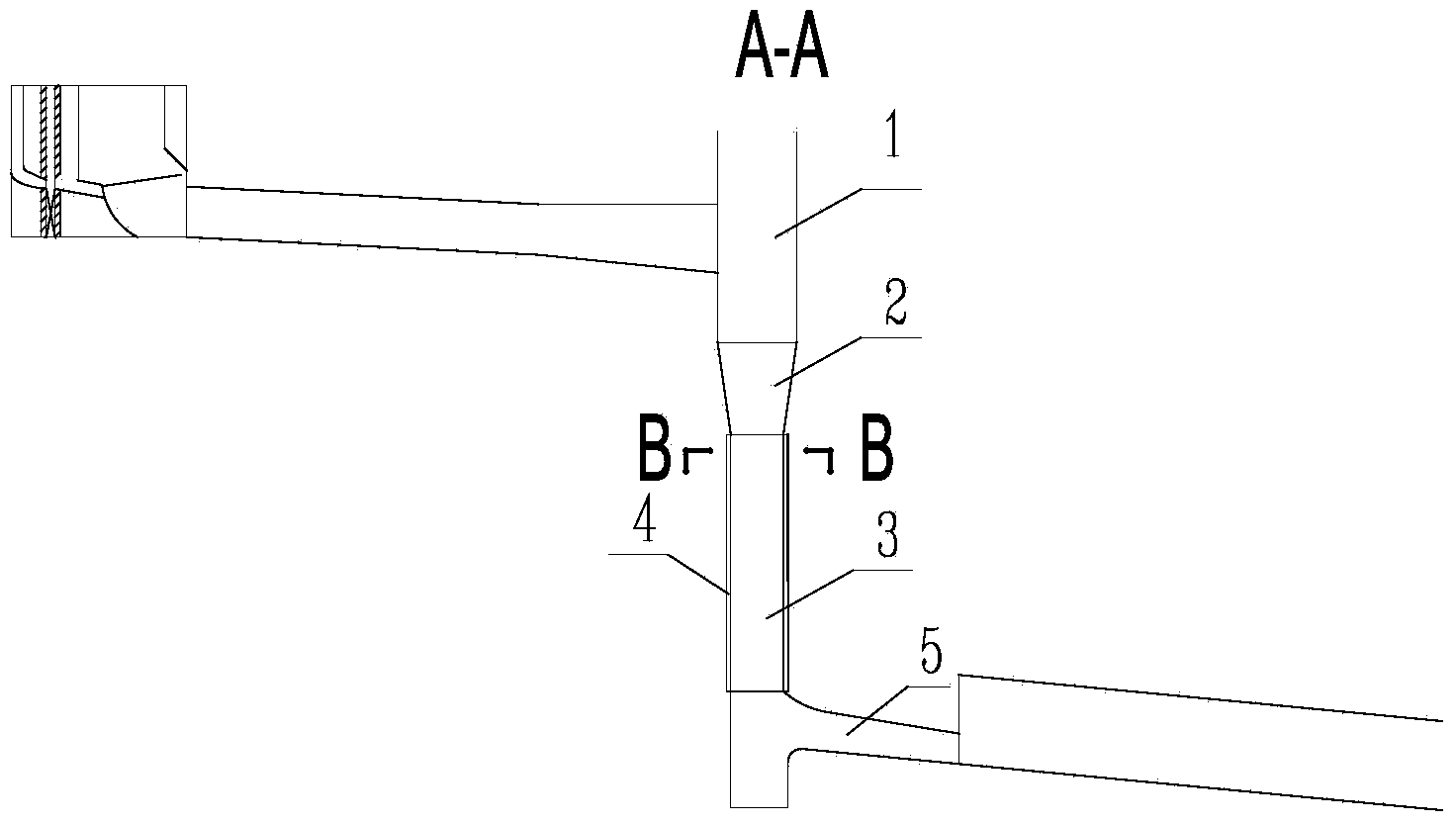

[0028] The swirl shaft of the whole process aeration provided in this embodiment is as follows: image 3 As shown, the swirl shaft is set on the vertical wall surface of the entire vertical shaft section 3 below the contraction section 2 of the conventional vertical shaft spillway and above the exit of the lower flat section 5 along the radial direction, and is provided with 2 channels running through the whole process. Air sill 4, the aeration sill 4 gradually closes to the wall surface formed by the original radius of shaft 3 with a smooth curved surface after sudden expansion, see Figure 4 . The aeration sill 4 provided can ensure that when the water flow rotates against the wall, an aeration cavity 6 will be generated, so that the water flowing through the wall of the entire shaft 3 is aerated water flow with a high concentration of gas, so as to completely avoid the aeration of the shaft. Cavitation erosion damage occurs on the wall surface.

[0029] From Figure 5 It...

Embodiment 2

[0031] The swirl shaft of the whole process aeration provided in this embodiment is as follows: Figure 6 As shown, the difference from the fully aerated cyclone shaft given in Example 1 is that the two aeration sills 4 provided in the shaft section 3 extend all the way to the bottom plate of the shaft, which is conducive to simple construction. All the other reasons are identical with embodiment 1, slightly.

Embodiment 3

[0033] The swirl shaft of the whole process aeration provided in the present embodiment is as follows: Figure 7 , 8 As shown, the difference from the full-process aerated swirl shaft given in Example 1 is that: 1) the two aeration sills 4 set in the shaft section 3 extend all the way to the bottom plate of the shaft; 2) the shaft section 3 is provided with There are 4 aeration sills, and the 4 aeration sills are evenly distributed in the circumferential direction of the shaft section. All the other reasons are identical with embodiment 1, slightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com