Antiskid woven cloth and preparation method thereof

A technology of woven cloth and anti-skid layer, applied in the field of woven cloth, can solve problems such as hidden safety hazards and ineffective use of storage space, and achieve the effect of maintaining beautiful appearance, simple processing method, and good processing formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Implementation example 1 A kind of preparation method of non-slip woven cloth, comprises steps:

[0019] 1). Drawing and weaving the low-density polyethylene material to form low-density polyethylene woven fabric;

[0020] 2). Preparation of anti-skid layer blend material;

[0021] 3). The anti-slip layer blend material prepared in step 2) is extruded and compounded by extrusion casting machine.

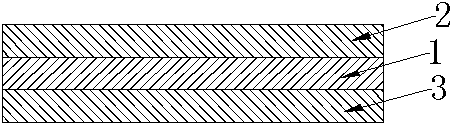

[0022] On the substrate low-density polyethylene woven fabric prepared by the above method, the inner and outer surfaces of the low-density polyethylene woven fabric are compounded to form a layer of anti-skid layer, that is, the outer anti-skid layer 2 and the inner anti-skid layer 3 can be obtained. Non-slip low-density polyethylene woven cloth.

[0023] 4). Roll, cut and pack the products produced in step 3).

[0024] The step 1) the warp and weft density of the low-density polyethylene woven cloth is 10×10, and the low-density polyethylene

[0025] The thickness of t...

Embodiment 2

[0030] Implementation example 2 A kind of preparation method of non-slip woven cloth, comprises steps:

[0031] 1). Drawing and weaving linear low density polyethylene material to form linear low density polyethylene woven fabric;

[0032] 2). Preparation of anti-skid layer blend material;

[0033] 3). The non-slip layer blend prepared in step 2) is extruded and compounded using an extrusion casting machine.

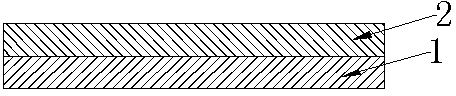

[0034] Formula coating is on the linear low density polyethylene woven cloth 1 prepared by the above method, and forms an outer anti-slip layer 2 on the linear low density polyethylene woven cloth. A non-slip linear low-density polyethylene woven cloth can be obtained.

[0035] 4). Rewind, cut and pack the products produced in step 3).

[0036] The warp and weft density of the linear low-density polyethylene woven cloth in the step 1) is 10×10, and the thickness of the linear low-density polyethylene woven cloth layer is 60g / m 2 .

[0037] The method for preparing...

Embodiment 3

[0042] Implementation example 3 A kind of preparation method of non-slip woven cloth, comprises steps:

[0043] 1). Drawing and weaving linear low density polyethylene material to form linear low density polyethylene woven fabric;

[0044] 2). Preparation of anti-skid layer blend material;

[0045] 3). The non-slip layer blend prepared in step 2) is extruded and compounded using an extrusion casting machine.

[0046] The formula coating is on the base polypropylene weaving 1 prepared by the above method, and an outer anti-slip layer 2 is formed on the polypropylene weaving cloth. A non-slip polypropylene woven cloth can be obtained.

[0047] 4). Rewind, cut and pack the products produced in step 3).

[0048] The warp and weft density of the linear low density polyethylene in the step 1 is 8×8, and the thickness of the linear low density polyethylene woven cloth layer is 80g / m 2 .

[0049] The method for preparing the anti-slip layer material in the step 2) includes: fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com