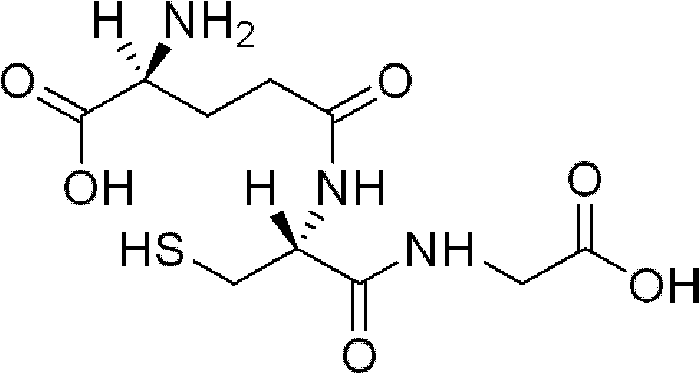

Method for separating and purifying reduced glutathione (GSH) from reduced glutathione contained fermentation leaching liquid

A technology for separation and purification of glutathione, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve problems such as no mention of purity information, and achieve the effects of mild conditions, easy operation, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 2L of GSH extract, containing 12.8g of GSH. Adjust the extract to pH 4.0 and purify it with gel-type strong base anion exchange resin FPA40, wash the resin with 3 times the volume of the resin in deionized water, then desorb with 0.1mol / L hydrochloric acid, and collect the desorbed concentration higher than 1mg / ml liquid and concentrated to 200ml. Adjust the concentrated solution to pH 2.8 with halogen-containing non-polar adsorption resin SP207, wash the resin with 3 times the resin volume of deionized water, desorb with 2% ethanol aqueous solution, and collect the reduced form after comprehensively considering the influence of yield and purity. Glutathione concentration: the ratio (R / O) of oxidized glutathione concentration is greater than 20 desorption solution and concentrated to 30ml, stir at room temperature and add a small amount of seed crystals and then add 15ml ethanol, continue to stir until the mother liquor concentration Significantly lower again, sto...

Embodiment 2

[0039]Take 2L of GSH fermentation broth, containing GSH12.1g. Adjust the extract to pH 4.0, use gel-type strong base anion exchange resin FPA40, wash the resin with deionized water 3 times the volume of the resin, then desorb with 0.1mol / L hydrochloric acid, and collect the desorption solution with a concentration higher than 1mg / ml And concentrated to 200ml. Adjust the concentrated solution to pH 2.8 with halogen-containing non-polar adsorption resin SP207, wash the resin with 3 times the resin volume of deionized water, desorb with 2% ethanol, and collect reduced glutathione concentration: oxidized glutathione Concentrate the desorption liquid with a ratio of glycylidene concentration greater than 20 to 30ml, stir at room temperature and add a small amount of seed crystals, then add 15ml of ethanol, continue to stir until the concentration of the mother liquor no longer decreases significantly, stop stirring, filter, and dry the crystals to obtain crystals 5.9 g, observed u...

Embodiment 3

[0041] Take 2L of GSH extract, containing 12.1g of GSH and 11.3g of glutathione. Adjust to pH 4.0 and purify with macroporous strong base anion exchange resin IRA900, wash the resin with deionized water 3 times the volume of the resin, desorb with 0.1mol / L hydrochloric acid, collect the desorbed solution with a concentration higher than 1mg / ml and concentrate to 200ml. Adjust the pH of the concentrated solution to 2.8 and purify it with halogen-containing non-polar adsorption resin SP207, wash the resin with 3 times the volume of the resin in deionized water, desorb with 2% ethanol, collect the desorbed solution with an R / O ratio greater than 20 and concentrate to 25ml, stir at room temperature and add a small amount of seed crystals, then add 12.5ml of ethanol, continue to stir until the concentration of the mother liquor no longer significantly decreases, stop stirring, filter, and dry the crystals to obtain 5.0g of crystals, with a total yield of 41.3%. The weight of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com