Device for cutting label sleeves from film tubes, device for mounting label sleeves and method for mounting label sleeves using the device

A technology of label sleeves and film tubes, which is applied in the directions of labeling, labeling, and labeling short rigid containers, etc., which can solve the problems of intensive maintenance, machine noise, and high belt wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

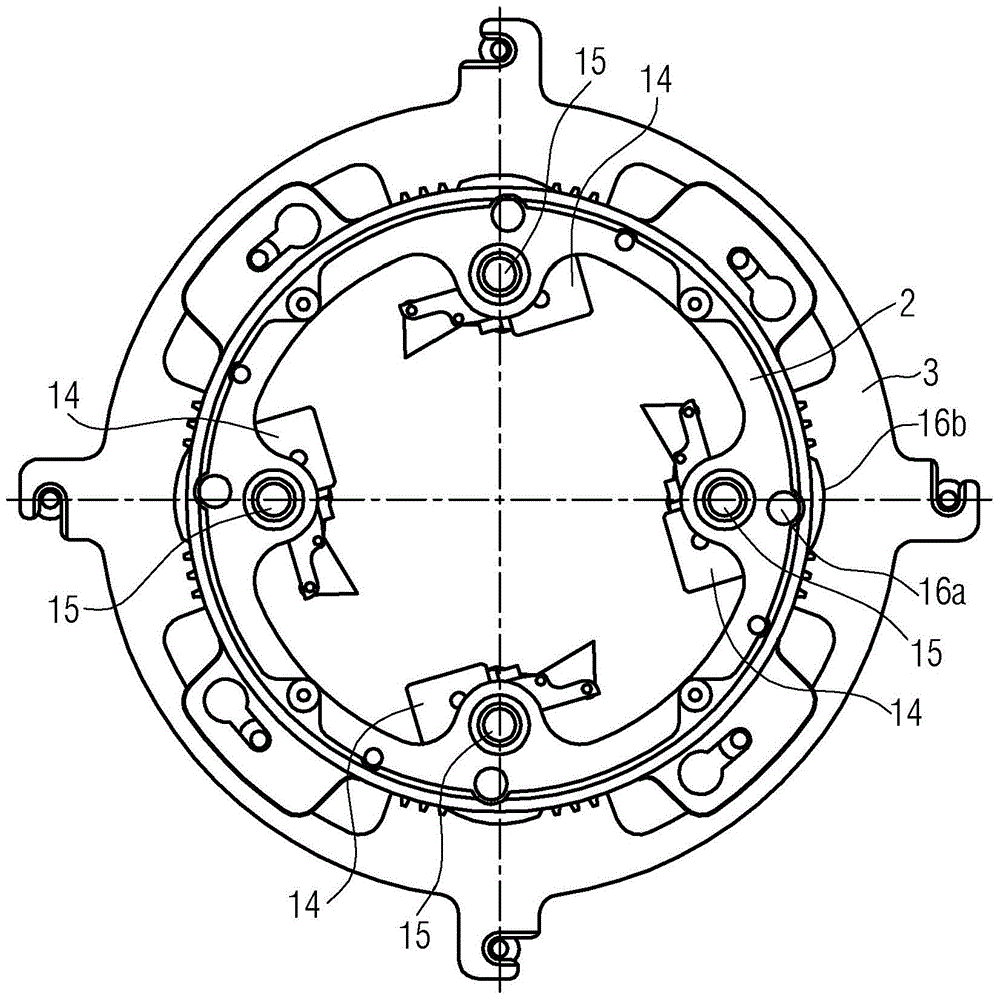

[0033] exist Figure 1a A device for cutting label sleeves from film tubes is shown in the direction of the axes of the knife holder and the knife manipulating ring. exist Figure 1a Can be seen here are the knife handling ring 3 , the knife holder 2 and the cutting knife 14 , which are mounted rotatably about an axis 15 . In this case, the cutting tool 14 is coupled mechanically, for example via pins 16 a , to the tool actuating ring 3 . The optionally present pivotable limiting region 16 b can limit the movement possibilities of the pin 16 , for example. exist Figure 1a The arrangement shown in can be operated in such a way that the tool handling ring and the tool carrier are run with toothed belts. If at least the tool steering ring or the tool holder is driven directly, then in Figure 1a The facility shown in can be included in a device according to the invention for cutting label sleeves from film tubes.

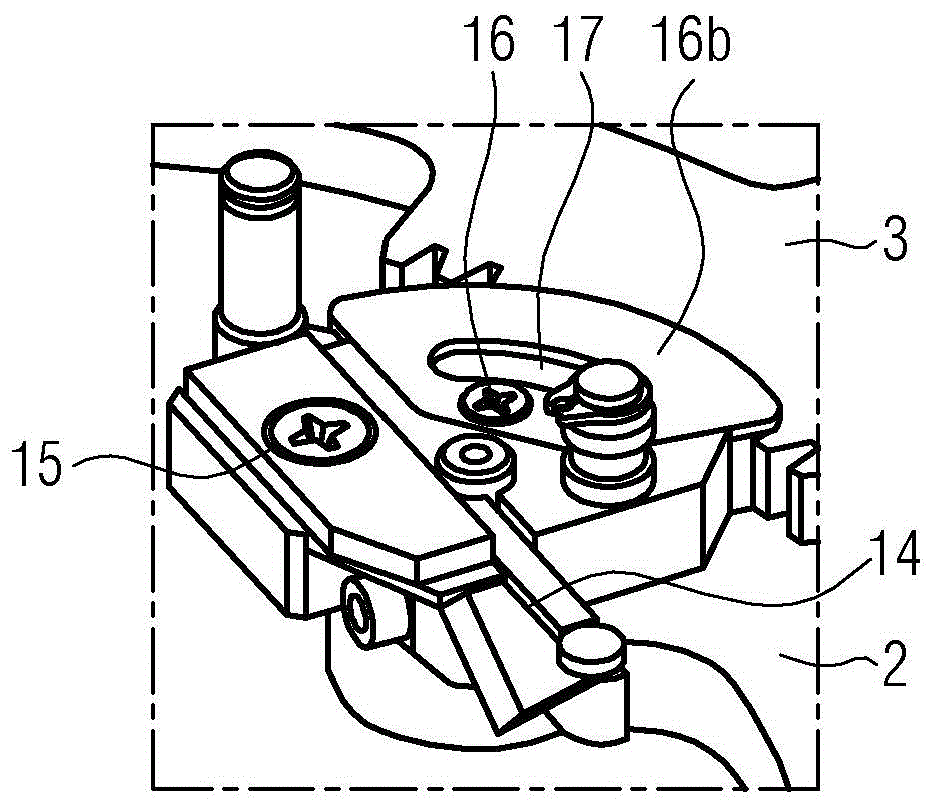

[0034] exist Figure 1b A detail of the device for cutting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com